Scratch-resistant special coating and preparation method thereof

A scratch-resistant and coating technology, used in polyester coatings, polyether coatings, coatings, etc., can solve the problems of unsatisfactory scratch resistance, easy precipitation of coatings, easy cracking of coatings, etc., and achieves excellent thixotropy and Wetting, excellent scratch resistance, breakage avoidance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

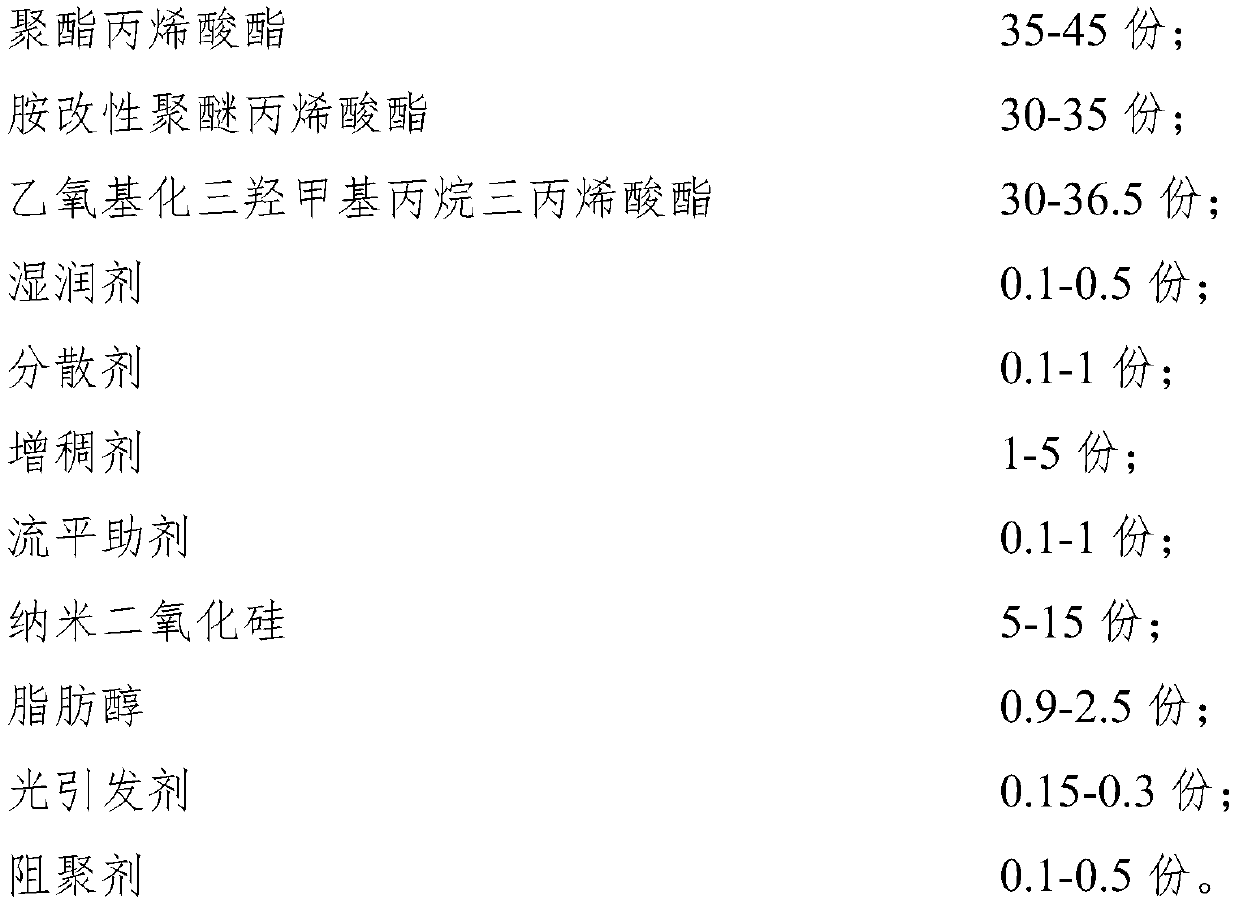

[0029] In the embodiment of the present invention, a scratch-resistant special coating includes the following raw materials in parts by weight:

[0030]

[0031]

[0032] A method for preparing a scratch-resistant special paint, comprising the following steps:

[0033] (1) Add polyester acrylate and amine-modified polyether acrylate to reactor A in sequence, and stir for 10-20min at a speed of 400-500r / min; , a dispersant, a thickener, a leveling aid and a polymerization inhibitor are added to the reactor A, and stirred for 30 minutes at a speed of 250-300r / min to obtain a solvent;

[0034] (2) Add nano-silica and aliphatic alcohol to autoclave B and react at 225-230° C. for 3 hours to obtain ethanol solvent;

[0035] (3) Slowly add the ethyl solvent into the reactor A, and stir for 20-30min at a speed of 400-450r / min;

[0036] (4) Add photoinitiator and ethoxylated trimethylolpropane triacrylate into reaction kettle A in sequence, and stir at 100-150 r / min for 20-25 m...

Embodiment 2

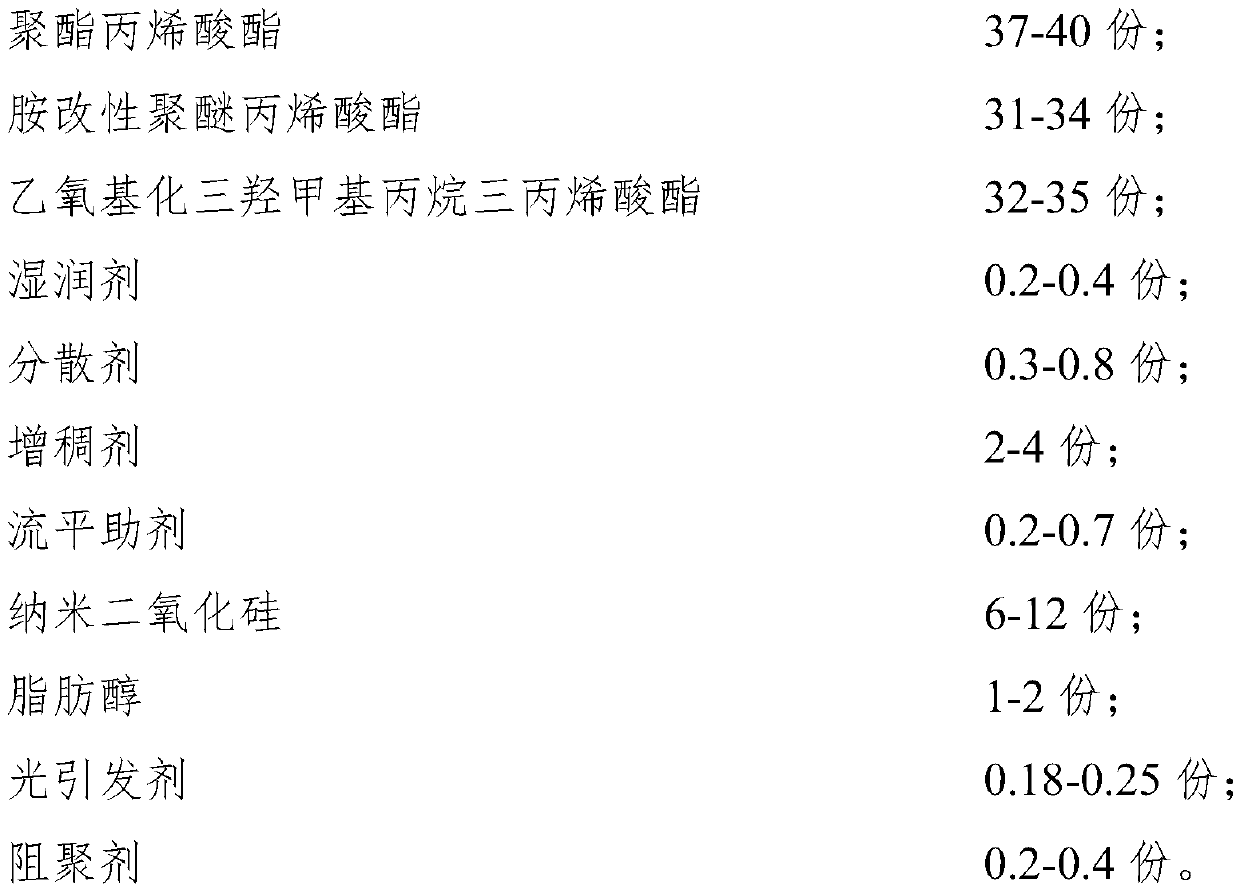

[0038] In the embodiment of the present invention, a scratch-resistant special coating includes the following raw materials in parts by weight:

[0039]

[0040] A method for preparing a scratch-resistant special paint, comprising the following steps:

[0041] (1) Add polyester acrylate and amine-modified polyether acrylate to reactor A in sequence, and stir for 10-20min at a speed of 450-500r / min; , a dispersant, a thickener, a leveling aid and a polymerization inhibitor are added to the reactor A, and stirred for 40-45min at a speed of 300-350r / min to obtain a solvent;

[0042] (2) Add nano silicon dioxide and aliphatic alcohol to autoclave B and react at 240-250° C. for 3h-3.5h to obtain ethanol solvent;

[0043] (3) Slowly add the ethyl solvent into the reactor A, and stir for 30-40min at a speed of 500-600r / min;

[0044] (4) Add photoinitiator and ethoxylated trimethylolpropane triacrylate into reaction kettle A in sequence, and stir for 25-30min at a rotating speed ...

Embodiment 3

[0046] In the embodiment of the present invention, a scratch-resistant special coating includes the following components by weight:

[0047]

[0048] A method for preparing a scratch-resistant special paint, comprising the following steps:

[0049] (1) Add polyester acrylate and amine-modified polyether acrylate to reactor A in turn, and stir for 10-20min at a speed of 400-450r / min; , a dispersant, a thickener, a leveling aid and a polymerization inhibitor are added to the reactor A, and stirred for 40-45min at a speed of 300-350r / min to obtain a solvent;

[0050](2) Add nano silicon dioxide and aliphatic alcohol to autoclave B and react at 225-230° C. for 3h-3.2h to obtain ethyl solvent;

[0051] (3) Slowly add the ethyl solvent into the reactor A, and stir for 20-30min at a speed of 400-500r / min;

[0052] (4) Add photoinitiator and ethoxylated trimethylolpropane triacrylate into reaction kettle A in sequence, and stir at 100-150 r / min for 20-25 min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com