A kind of method for preparing high f value oligopeptide using chlorella powder as raw material

A chlorella and oligopeptide technology, applied in the field of protein preparation, can solve the problems of imperfect process, easy formation of inclusion bodies, short synthetic sequence, etc., and achieves the effects of good solubility, reduced production cost and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Example 1 Obtaining of recombinant carboxypeptidase (CPA)

[0033] 1. Cloning of Aspergillus niger M00988 CPA and construction of expression vector

[0034] According to the carboxypeptidase gene sequence of NCBI Aspergillus niger, two pairs of primers CPA-F / CPA-R were designed, and the sequences are shown in Table 1.

[0035] Table 1 The sequences of primers for carboxypeptidase gene cloning

[0036]

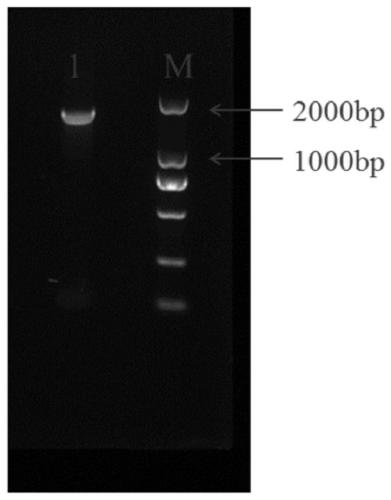

[0037] The DNA of Aspergillus niger M00988 (CGMCC No. 18828) was extracted as a template, and the sequence is shown in SEQ ID NO: 6. The target gene fragment CPA was obtained by PCR amplification with CPA-F / CPA-R primers. The PCR amplification conditions are: pre-denaturation at 94°C for 5 minutes, then denaturation at 94°C for 30 seconds, annealing at 68°C for 1 minute, extension at 72°C for 1 minute, 35 cycles, and extension at 72°C for 10 minutes to obtain a fragment with a size of about 1500 bp, which was detected by agarose electrophoresis Such as figure 1 s...

Embodiment 2

[0050] Example 2 Preparation of high F value oligopeptide

[0051] 1. Chlorella protein extraction

[0052] Accurately weigh a certain amount of chlorella powder, put it in a 250mL Erlenmeyer flask, add deionized water according to the appropriate amount of material-to-liquid ratio g / mL, stir, put it in a shaker, and swell at room temperature at 200rpm for 12 hours. Add an appropriate amount of solid sodium hydroxide to the swollen chlorella suspension, add slowly and keep stirring during the addition process. After completion, sonicate at a certain temperature and time. Next, use 0.1mol / L sodium hydroxide solution and hydrochloric acid solution to adjust the pH=7, centrifuge at 5000rpm 25°C for 10min, take the supernatant, measure the volume with a graduated cylinder and record it, then take 10mL from it into the Erlenmeyer flask to 1:4 (V / V) solid-liquid ratio, add 95% ethanol solution at 4°C, stir for 1min, and mix thoroughly. Centrifuge again at 5000 rpm at 25° C. for 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com