Air heating reflux system for low-temperature starting of fuel cell and control method

A fuel cell and air heating technology, applied in the direction of fuel cell heat exchange, fuel cells, fuel cell additives, etc., can solve problems affecting safety, uneven heat distribution, stack damage, etc., to reduce air energy consumption loss, prolong service life, and prevent excessive discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

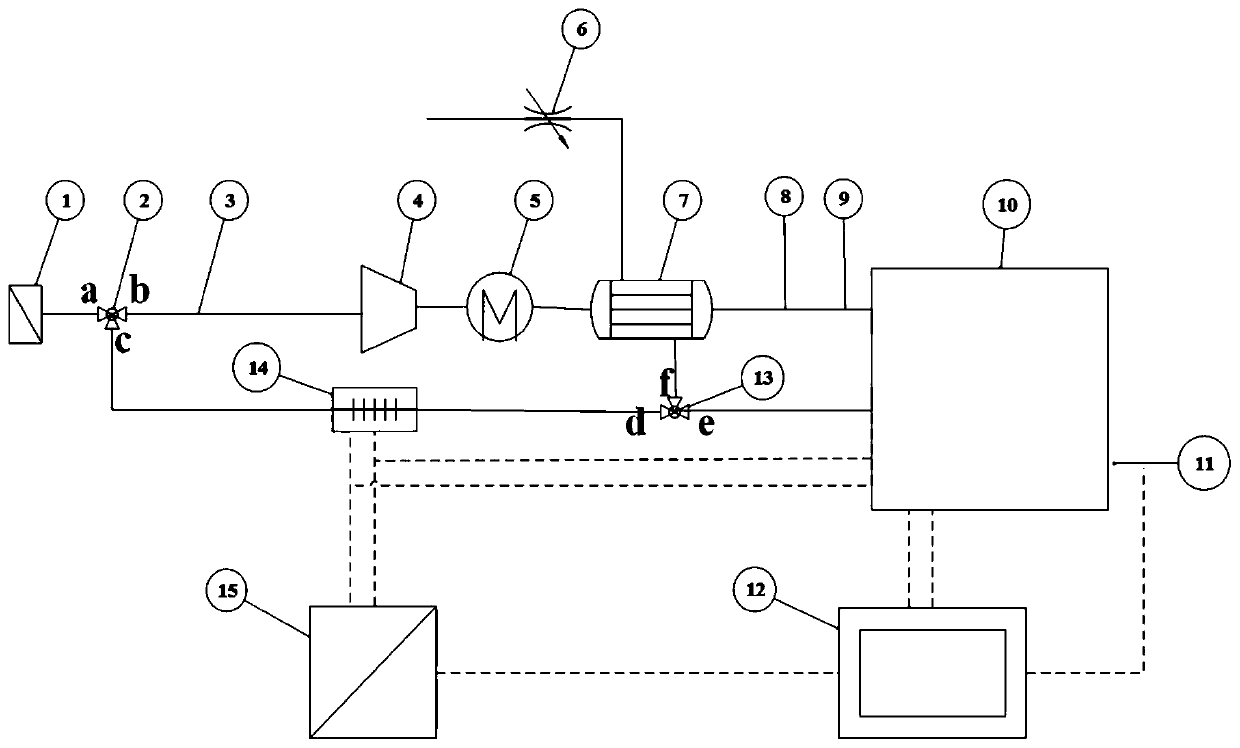

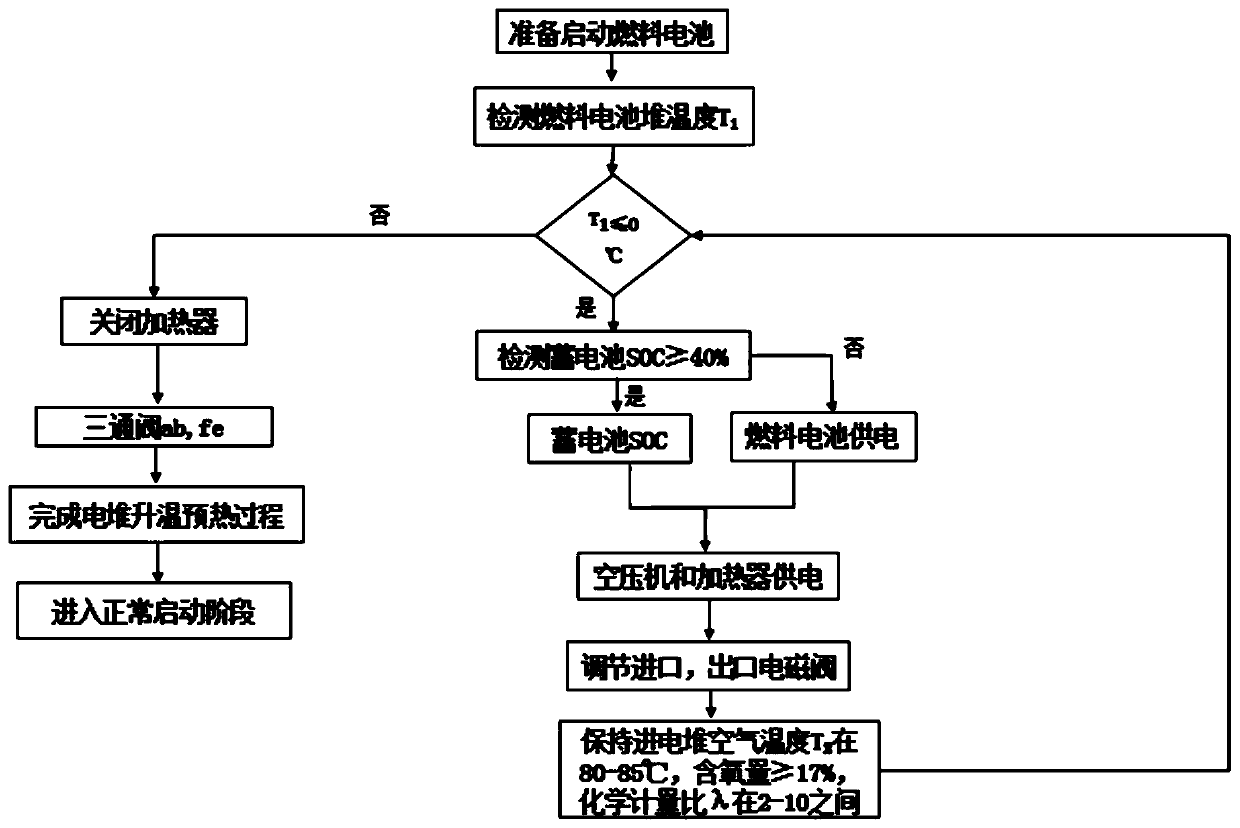

[0040] According to the prior art, the temperature of the compressed air will increase, and the heat of the compressed air can be directly transferred to the reaction surface of the catalyst with a fast heat transfer rate, so the heat can be used to heat the stack at low temperature. However, due to the need to reduce the power consumption and boosting capacity of the air compressor as much as possible at low temperatures, the pressure ratio Pr needs to be controlled between 1.1-1.3. The device 14 heats the inlet temperature to meet the requirements of the stacking temperature and flow rate at the same time.

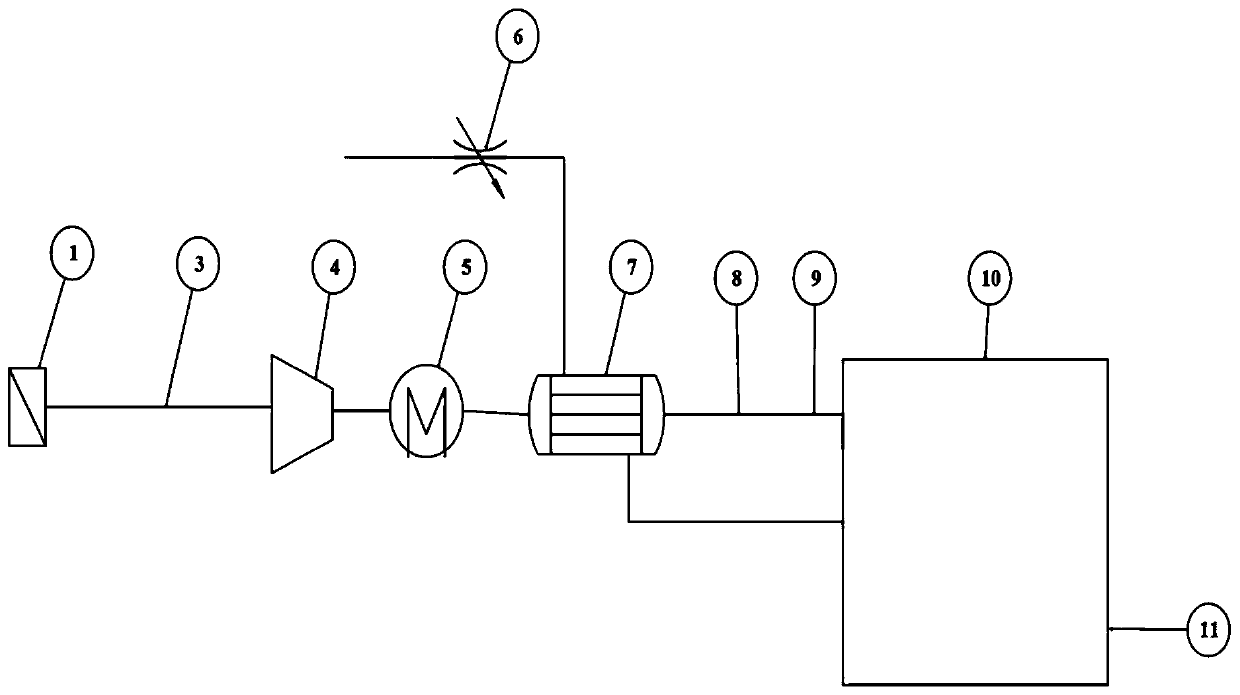

[0041] Such as figure 2 As shown, the present invention provides a fuel cell low-temperature starting air heating return system, which specifically includes: an air filter 1, an inlet three-way valve 2, a mass flow sensor 3, an air compressor 4, an intercooler 5, an outlet back pressure valve 6, Humidifier 7, stack inlet temperature sensor 8, stack inlet pressure senso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com