Modified rice husk biochar and preparation method and application thereof

A technology of biochar and chaff, which is used in carbon preparation/purification, application, fertilizer mixture, etc., can solve the problems of excessive heavy metals, food safety, etc., and achieve the effect of increasing specific surface area, increasing mineral elements, and passivating soil cadmium

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

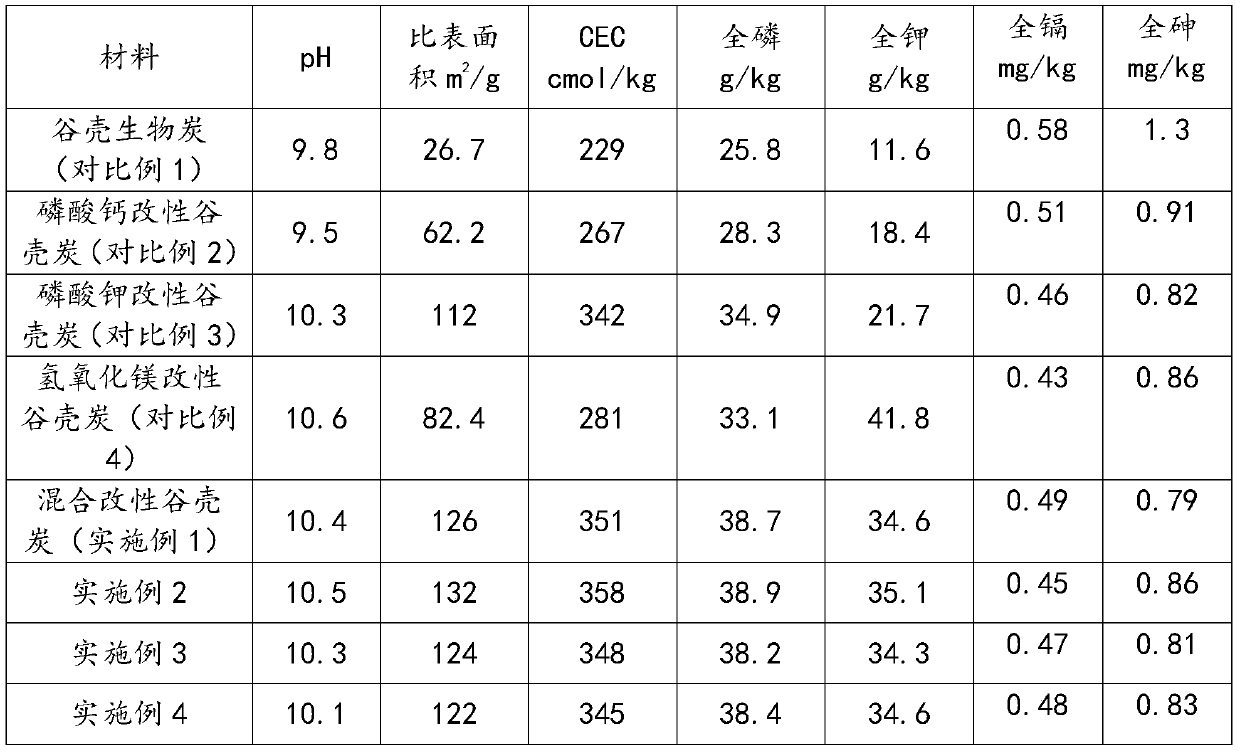

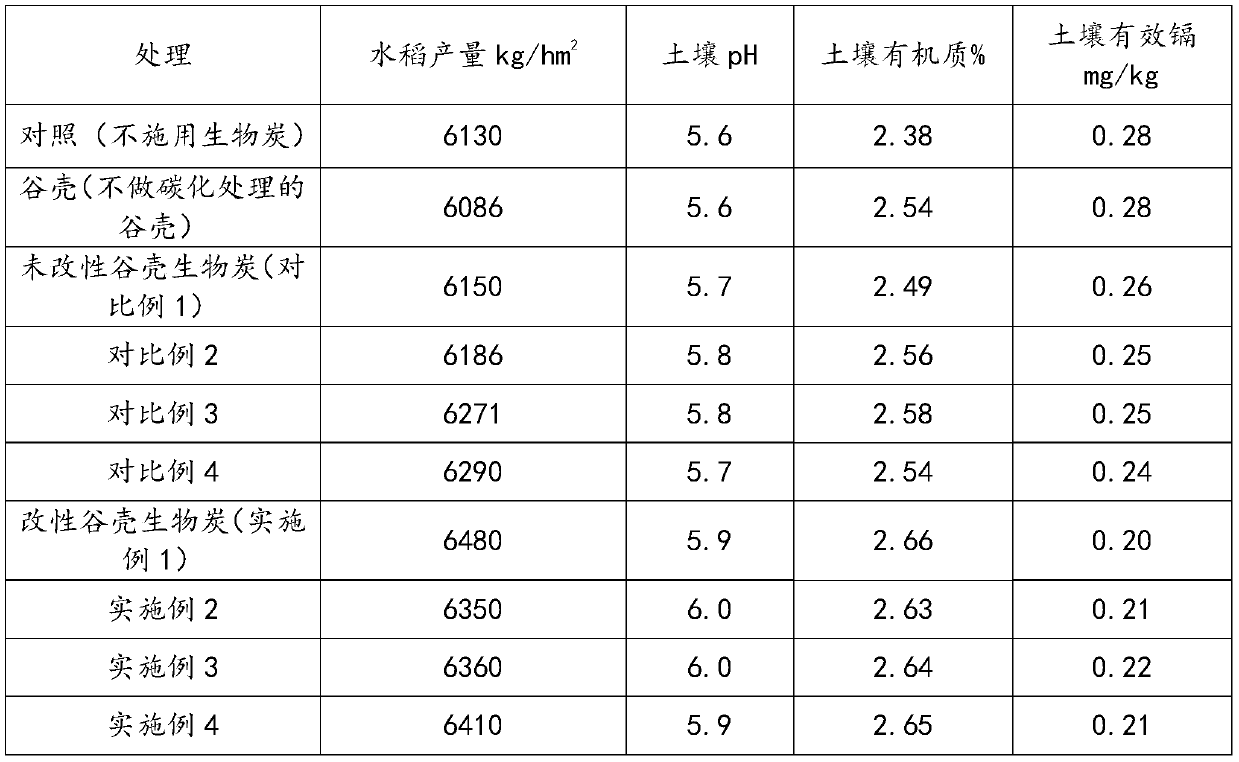

[0024] The present embodiment provides a kind of preparation method of modified rice husk biochar, comprising the following steps:

[0025] Step 1. Carbonizing chaff to obtain chaff biochar: thermally decompose the dried chaff at 300°C for 2-4 hours in an oxygen-free environment to prepare chaff biochar, and grind it through a 300-mesh sieve for later use;

[0026] Step 2. Modification of rice husk biochar: Add the rice husk biochar obtained in step 1 to the modified salt, stir and shake for 24 hours, filter, and dry at 100°C; then pyrolyze and modify it under nitrogen at 600°C for 30 minutes to prepare Obtain this modified rice husk biochar; The modified salt is 100mL of suspension prepared from calcium phosphate (10g), potassium phosphate (5g) and magnesium hydroxide (5g) with a weight ratio of 2:1:1 , the total mass of the modified salt is 40% of the rice husk biochar mass (50g).

Embodiment 2

[0028] The present embodiment provides a kind of preparation method of modified rice husk biochar, comprising the following steps:

[0029] Step 1. Carbonizing chaff to obtain chaff biochar: thermally decompose the dried chaff at 400°C for 2-4 hours in an oxygen-free environment to prepare chaff biochar, and grind it through a 100-mesh sieve for later use;

[0030] Step 2. Modification of rice husk biochar: add the rice husk biochar obtained in step 1 to the modified salt, stir and shake for 24 hours, filter, and dry at 100°C; then pyrolyze and modify it under 550°C nitrogen environment for 60 minutes to prepare Obtain the modified rice husk biochar; the modified salt is a suspension prepared from calcium phosphate (10g), potassium phosphate (7.5g) and magnesium hydroxide (5g) with a weight ratio of 2:1.5:1 100mL, the total mass of the modified salt is 45% of the rice husk biochar mass (50g).

Embodiment 3

[0032] The present embodiment provides a kind of preparation method of modified rice husk biochar, comprising the following steps:

[0033] Step 1, chaff carbonization to obtain chaff biochar: dry chaff is thermally cracked at 500°C for 2 to 4 hours in an oxygen-free environment to prepare chaff biochar, and grind it through a 500-mesh sieve for later use;

[0034] Step 2. Modification of rice husk biochar: add the rice husk biochar obtained in step 1 to the modified salt, stir and shake for 36 hours, filter, and dry at 100°C; then pyrolyze and modify it in a nitrogen environment of 550°C for 90 minutes to prepare Obtain this modified rice husk biochar; The modified salt is 100mL of suspension prepared from calcium phosphate (15g), potassium phosphate (10g) and magnesium hydroxide (5g) with a weight ratio of 3:2:1 , the total mass of the modified salt is 30% of the rice husk biochar mass (100g).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com