Efficient composite phosphorus removal type farmland tail water treatment system and preparation method thereof

A composite phosphorus removal type and treatment system technology is applied in the field of high-efficiency composite phosphorus removal type farmland tail water treatment system and its preparation field, which can solve the problems of easy breeding of algae, affecting water supply safety, and limited effectiveness in reducing the total phosphorus index. Good sewage purification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

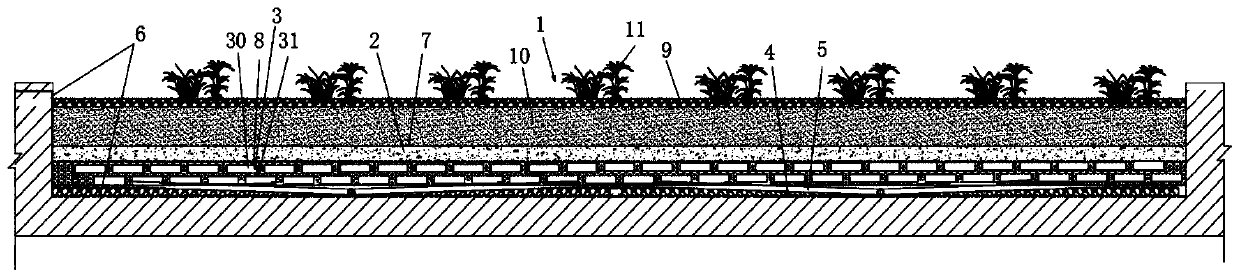

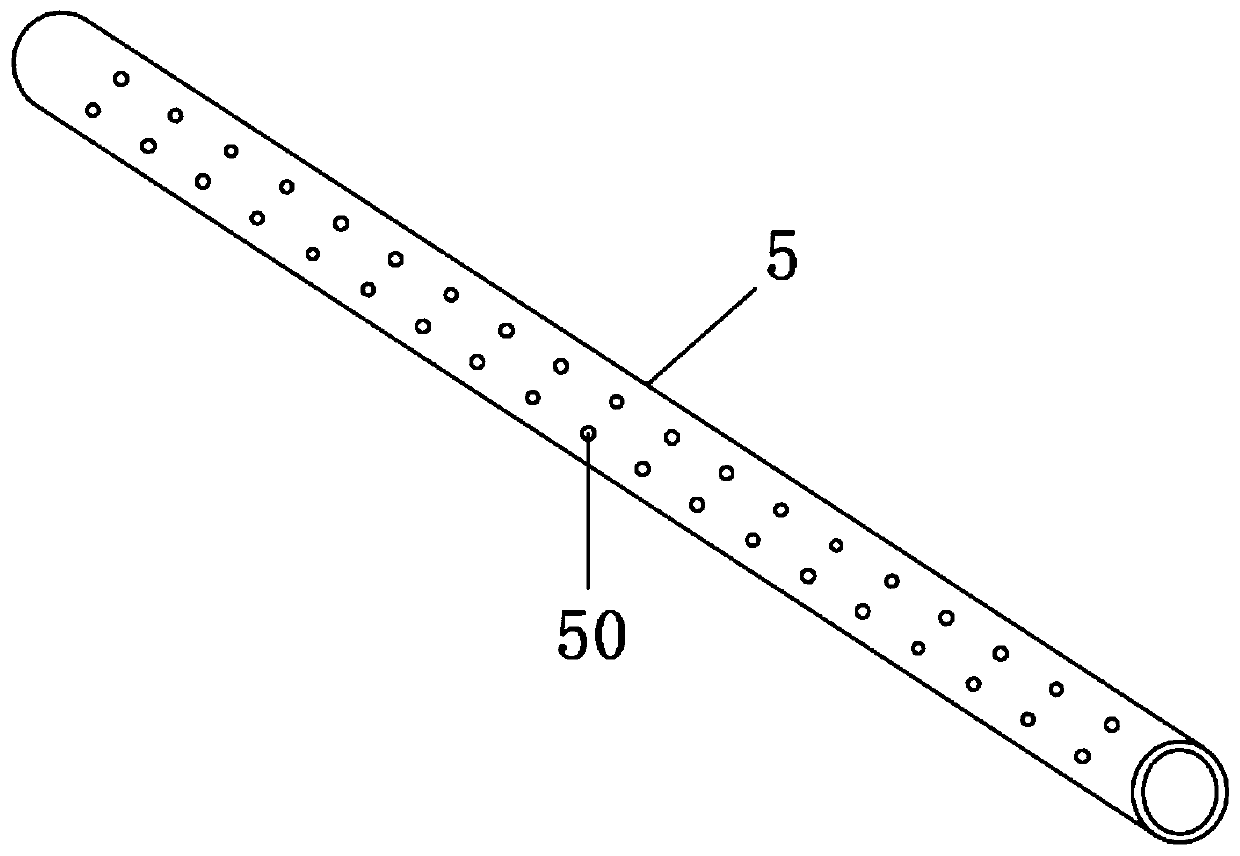

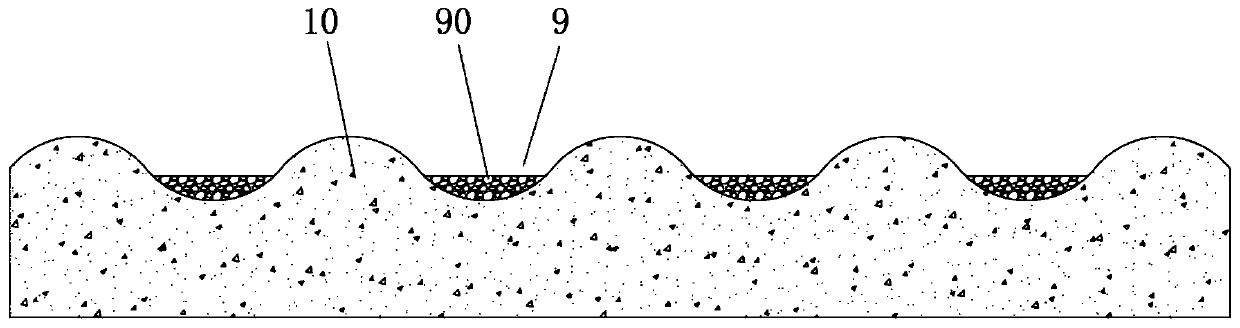

[0036] see Figure 1 to Figure 3 As shown, a preparation method of a high-efficiency composite phosphorus removal type farmland tail water treatment system comprises the following steps:

[0037] S1, 75% of gravel by weight, 6% of zero-valent iron with a diameter of 3mm, 4% of zero-valent aluminum with a diameter of 3mm, 8% of activated carbon powder and 7% of rice husk are uniformly mixed to obtain a dephosphorization mixture material; then the phosphorus-removing mixture is packed into a water-permeable geotextile bag and the opening is sealed to obtain an enhanced phosphorus-removing geotextile bag 30;

[0038] S2. Carry out earthwork excavation on the base position, then compact the bottom of the earthwork groove, the degree of compaction at the bottom of the earthwork groove is 97%; lay the anti-seepage cloth 6 on the bottom and side of the compacted earthwork groove, and then Lay crushed stone material 4 with a particle size of 12mm on the top of the anti-seepage cloth ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| osmotic coefficient | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com