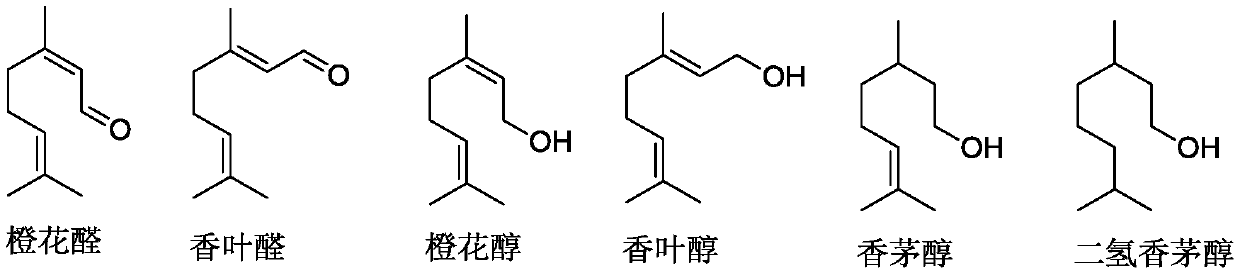

Method for preparing nerol and geraniol from citral

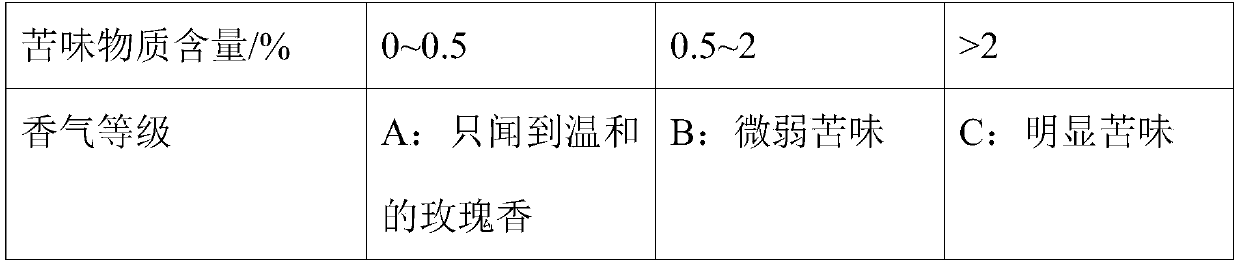

A technology of nerol and citral, which is applied in chemical instruments and methods, preparation of hydroxyl compounds, preparation of organic compounds, etc., can solve the problems of unenvironmental protection and large waste water in the production process, and achieve good industrial application value, high quality, The effect of eliminating bitterness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] According to the metal element: organic ligand: solvent molar ratio 3:1:20, weigh 2.07g ruthenium trichloride, 0.55g terephthalic acid and 4.87g N,N-dimethylformamide in tetrafluoroethylene In the lined autoclave, stir evenly, tighten and seal the autoclave, heat to 160 °C, keep the temperature for 72 hours, then cool down to 30 °C at a rate of 4 °C / min, open the autoclave and take a sample, which is recorded as MOFs-1.

[0059] The MOFs-1 were immersed in a petroleum ether solution with a silicon content of 5 wt%. The silicon source was tetraethyl orthosilicate. After vacuum impregnation for 15 hours, it was dried at 30°C for 15 hours, and then placed in a muffle furnace at a temperature of 3°C / Slowly raise the temperature to 500°C at a heating rate of min, and then calcine for 2 hours. At this point, a silicon deposition operation is completed. After the deposition is repeated 2 times, the finished catalyst 1# is obtained.

Embodiment 2

[0063] According to the metal element: organic ligand: solvent molar ratio 2:1:30, weigh 6.22g ruthenium trichloride, 2.49g terephthalic acid and 32.89g N,N-dimethylformamide in a PTFE liner In a pressure-resistant environment, stir evenly, tighten and seal the autoclave, heat it to 180°C, keep it warm for 12 hours, then cool it down to 30°C at a rate of 6°C / min, open the autoclave to take a sample, and record it as MOFs-2.

[0064] The MOFs-2 were immersed in a petroleum ether solution with a silicon content of 2wt%. The silicon source was tetraethyl orthosilicate. After vacuum impregnation for 20 hours, it was dried at 30°C for 20 hours, and then placed in a muffle furnace at 2°C / Slowly raise the temperature to 550°C at a heating rate of min, and then calcine for 1 hour. At this point, a silicon deposition operation is completed. After the deposition is repeated 3 times, the finished catalyst 2# is obtained.

[0065] The molar ratio of ruthenium, terephthalic acid and Si in...

Embodiment 3

[0068] According to the metal element: organic ligand: solvent molar ratio 4:1:25, weigh 10.37g ruthenium trichloride, 2.08g terephthalic acid and 22.84g N,N-dimethylformamide in a PTFE liner In a pressure-resistant environment, stir evenly, tightly seal the autoclave, heat it to 150°C, keep it warm for 50 hours, then cool it down to 30°C at a rate of 10°C / min, open the autoclave to take a sample, and record it as MOFs-3.

[0069] According to the method of equal volume impregnation, MOFs-3 was impregnated in petroleum ether solution with a silicon content of 8wt%. The silicon source was tetraethyl orthosilicate. After vacuum impregnation for 10 hours, it was dried at 30°C for 10 hours, and then placed in a muffle furnace. In the process, the temperature was slowly raised to 520°C at a heating rate of 4°C / min, and then calcined for 1.5 hours. At this point, a silicon deposition operation was completed, and the finished catalyst 3# was obtained after repeating the deposition 4 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com