Quick-drying core-shell structure hydroxy acrylic emulsion, preparation method and application thereof

A technology of structural hydroxyacrylic acid and methyl methacrylate, which is applied in coatings, polyurea/polyurethane coatings, etc., can solve the problems of high VOC content, high curing agent price, and complicated preparation process, and achieve gloss and vivid image The effect of high strength, faster drying speed and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A quick-drying core-shell structure hydroxyacrylic acid emulsion, which is obtained by performing two consecutive emulsion polymerizations of core layer monomers and shell layer monomers with a mass ratio of 1:1;

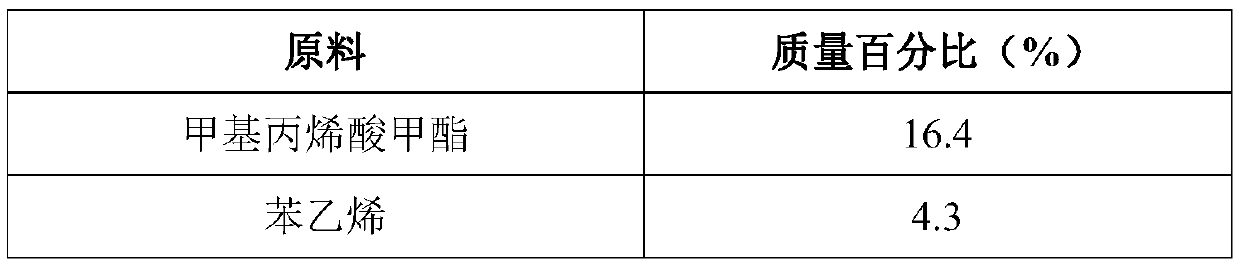

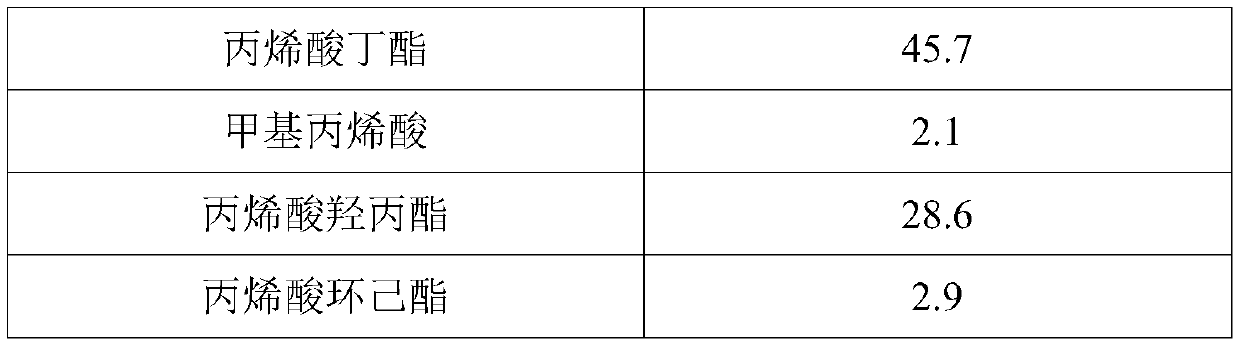

[0046] The composition of the nuclear layer monomer is shown in the following table:

[0047] Table 1 Composition of nuclear layer monomers

[0048] raw material Mass percentage (%) Methyl methacrylate 61 Styrene 15 Butyl acrylate 22.8 Ethylene glycol diacrylate 1.2

[0049] The composition of the shell monomer is shown in the table below:

[0050] Table 2 Composition table of shell monomer

[0051] raw material Mass percentage (%) Methyl methacrylate 6 Styrene 15 Butyl acrylate 44 Methacrylate 4 Hydroxyethyl methacrylate 23 Isobornyl Acrylate 8

[0052] The preparation method of the above-mentioned quick-drying type core-shell structure hydroxyacrylic acid emulsion c...

Embodiment 2

[0062] A quick-drying core-shell structure hydroxyacrylic acid emulsion, which is obtained by performing two consecutive emulsion polymerizations of core layer monomers and shell layer monomers with a mass ratio of 1:9;

[0063] The composition of the nuclear layer monomer is shown in the following table:

[0064] Table 3 Composition of nuclear layer monomers

[0065] raw material Mass percentage (%) Methyl methacrylate 94 Butyl acrylate 6

[0066] The composition of the shell monomer is shown in the table below:

[0067] The composition table of table 4 shell monomer

[0068] raw material Mass percentage (%) Methyl methacrylate 36.1 Butyl acrylate 38.8 acrylic acid 0.6 Hydroxypropyl Acrylate 16.7 Hydroxyethyl Acrylate 5.6 Isobornyl Methacrylate 2.2

[0069] The preparation method of the above-mentioned quick-drying type core-shell structure hydroxyacrylic acid emulsion comprises the following ste...

Embodiment 3

[0079] A quick-drying type core-shell structure hydroxyacrylic acid emulsion, which is obtained by two consecutive emulsion polymerizations of core layer monomers and shell layer monomers with a mass ratio of 3:7;

[0080] The composition of the nuclear layer monomer is shown in the following table:

[0081] Table 5 Composition of nuclear layer monomers

[0082] raw material Mass percentage (%) Methyl methacrylate 77.7 Styrene 6.6 Butyl acrylate 14.7 Ethylene glycol diacrylate 1

[0083] The composition of the shell monomer is shown in the table below:

[0084] The composition table of table 6 shell monomer

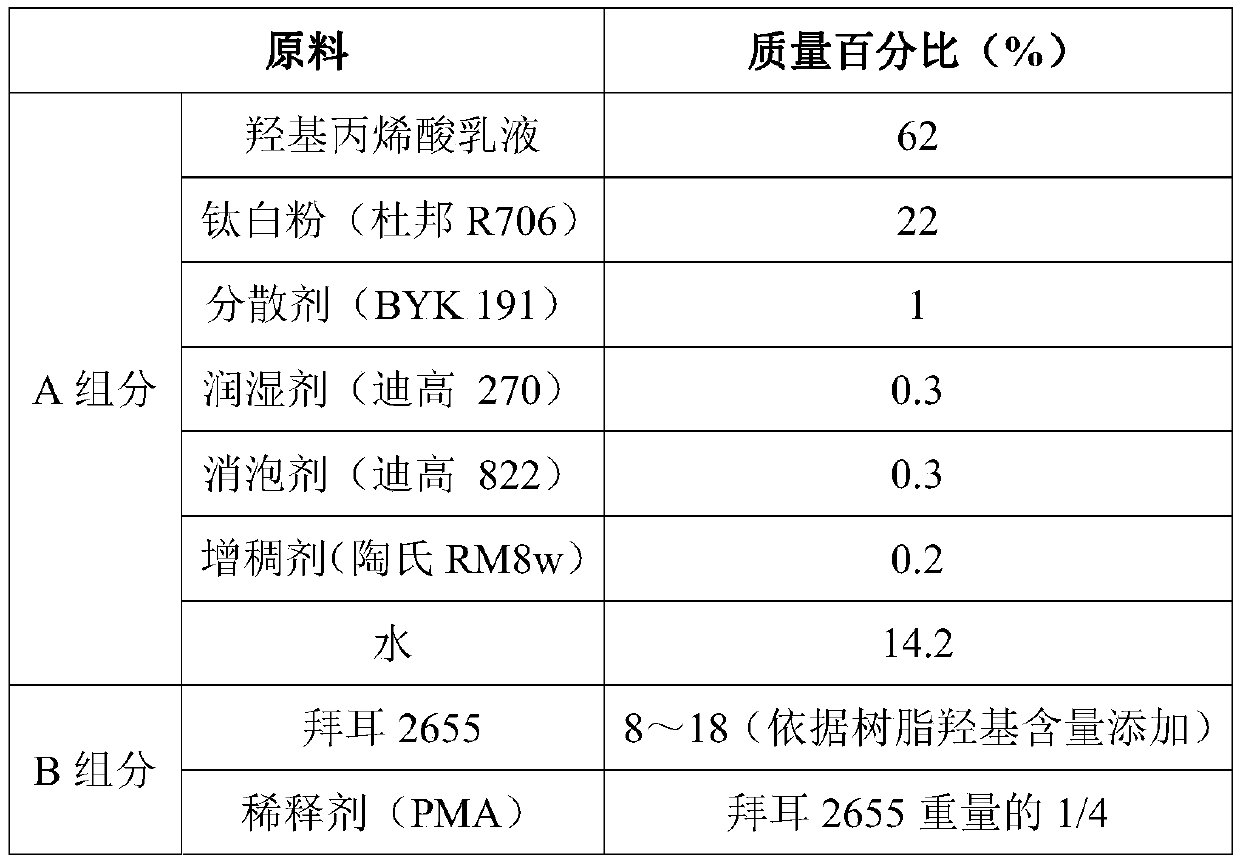

[0085]

[0086]

[0087] The preparation method of the above-mentioned quick-drying type core-shell structure hydroxyacrylic acid emulsion comprises the following steps:

[0088] 1) uniformly dispersing the core layer monomer and the alkylphenol polyoxyethylene ether sulfate with water to obtain a pre-emulsion A;

[0089] 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com