High-refractive-index transparent silica gel as well as preparation method and application thereof

A technology of high refractive index and silicone gel, applied in the field of silicone gel, can solve the problems of low toughness, low penetrability of silicone gel, weak force, etc., and achieve high light transmittance and high temperature stability, Suitable for large-scale production and application, the effect of good adhesion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0104] The present invention also provides a method for preparing the high-refractive-index transparent silica gel described in the above-mentioned technical solution, comprising the following steps:

[0105] a) Mix the phenyl-terminated vinyl silicone oil, the phenyl-terminated side-chain vinyl silicone oil and the platinum catalyst evenly, remove air bubbles, and obtain component A;

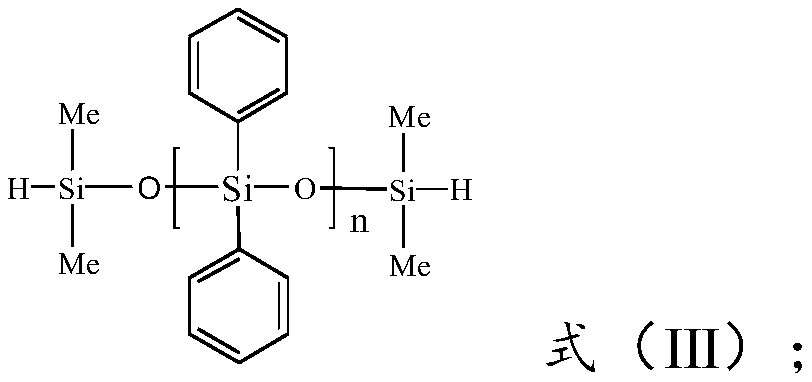

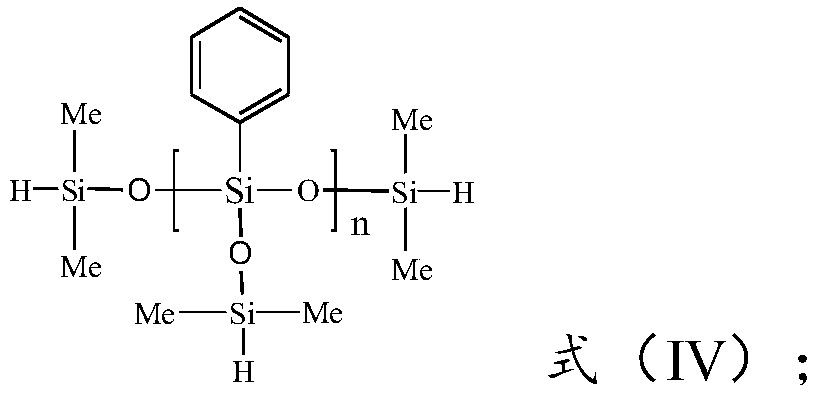

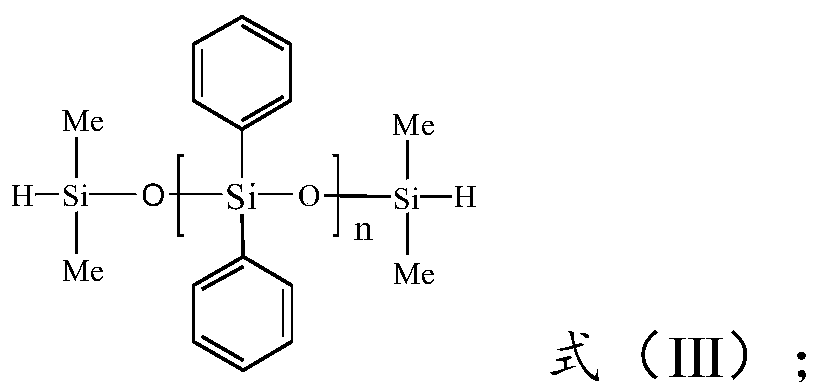

[0106] Mix phenyl-terminated vinyl silicone oil, phenyl-terminated side-chain vinyl silicone oil, bisphenyl hydrogen-containing chain extender, phenyl hydrogen-containing crosslinking agent, phenyl tackifier and inhibitor, and remove air bubbles to obtain Component B;

[0107] b) The above component A and component B are mixed evenly, and air bubbles are removed to obtain a high refractive index transparent silicone gel.

[0108] In the present invention, the order of obtaining component A and component B is not particularly limited. In the present invention, the phenyl-terminated vinyl silic...

Embodiment 1

[0122] (1) Mix phenyl-terminated vinyl silicone oil, phenyl-terminated side-chain vinyl silicone oil, and platinum catalyst evenly, and remove air bubbles to obtain Component A;

[0123] Mix phenyl-terminal vinyl silicone oil, phenyl-terminal side-chain vinyl silicone oil, bisphenyl hydrogen-containing chain extender, phenyl hydrogen-containing cross-linking agent, phenyl tackifier, inhibitor, and remove air bubbles to obtain Component B;

[0124] See Table 1 for the material formula table in Example 1 of the present invention.

[0125] The material formula table in the embodiment of the present invention 1 of table 1

[0126]

[0127]

[0128] (2) Take 50g of the above-mentioned component A and component B and mix them uniformly for defoaming to obtain a high-refractive index transparent silicone gel; in the mixture of component A and component B, there are substances with silicon-hydrogen bonds and vinyl groups The amount ratio is 0.85.

[0129] Usage method: Add 40...

Embodiment 2

[0131] (1) Mix phenyl-terminated vinyl silicone oil, phenyl-terminated side-chain vinyl silicone oil, and platinum catalyst evenly, and remove air bubbles to obtain Component A;

[0132] Mix phenyl-terminal vinyl silicone oil, phenyl-terminal side-chain vinyl silicone oil, bisphenyl hydrogen-containing chain extender, phenyl hydrogen-containing cross-linking agent, phenyl tackifier, inhibitor, and remove air bubbles to obtain Component B;

[0133] See Table 2 for the material formula table in Example 2 of the present invention.

[0134] Material formula table in the embodiment of the present invention 2 in table 2

[0135]

[0136]

[0137] (2) Take 50g of the above-mentioned component A and component B and mix them uniformly for defoaming to obtain a high-refractive index transparent silicone gel; in the mixture of component A and component B, there are substances with silicon-hydrogen bonds and vinyl groups The amount ratio is 0.80.

[0138] Usage method: Add 40g of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com