Freeze-dried powder and preparation method thereof

A technology of freeze-dried powder and mother liquor, which is applied in the direction of pharmaceutical formulations, cosmetic preparations, dressing preparations, etc., can solve the problems of reducing the rate of sterile filtration, affecting the resolubility of freeze-dried powder, and increasing the difficulty of sterile filtration, etc., to achieve The price of raw materials is cheap, the requirements for professional quality are low, and the effect of smooth and delicate appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

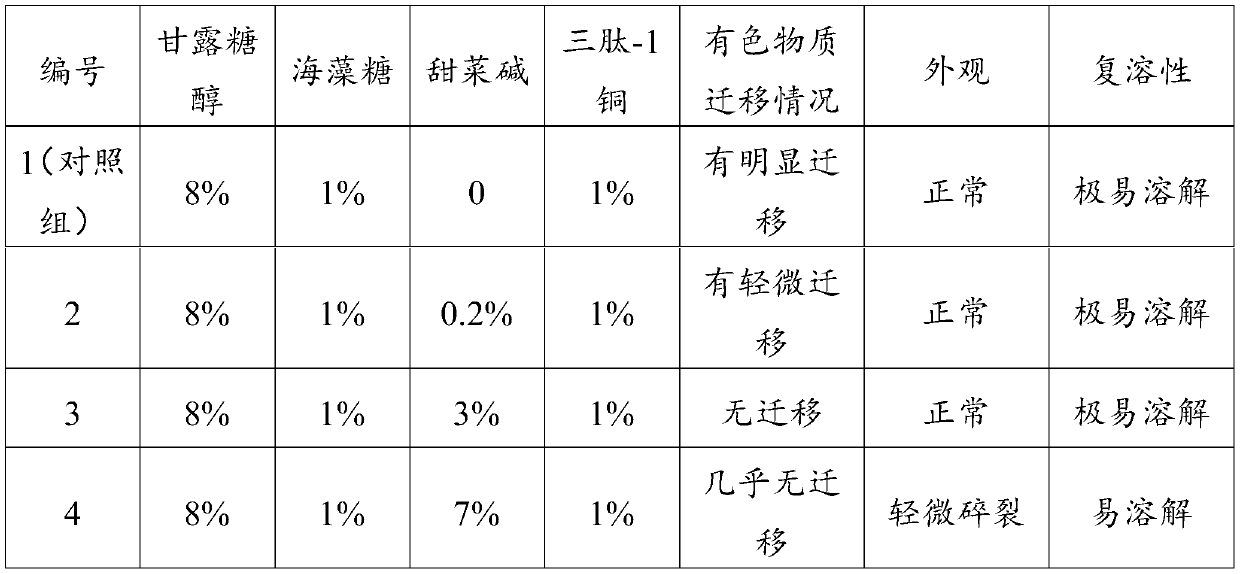

[0025] The purpose of this example is to compare the impact of the addition of betaine on the migration of colored substances (tripeptide-1 copper) and other indicators during the freeze-drying process

[0026] In the present embodiment, three kinds of lyophilized powders (No. 2, 3, 4) according to the present invention and a kind of lyophilized powder (No. 1, control group) not containing betaine were carried out to carry out the migration of colored substances, appearance and The detection or observation of the resolubility and the resolubility test all use physiological saline for the dissolution test, and the results are shown in Table 1.

[0027] The freeze-dried powder of No. 1 includes the following components in terms of weight percentage: 1% of tripeptide-1 copper, 1% of trehalose, 8% of mannitol, and 90% of deionized water.

[0028] The freeze-dried powder of No. 2, in terms of weight percentage, said freeze-dried powder comprises the following components: tripeptide...

Embodiment 2

[0040] The purpose of this example is to compare the effects of different concentrations of mannitol in the freeze-dried powder on the migration, appearance and resolubility of the colored substances in the freeze-dried powder

[0041] In this example, three kinds of freeze-dried powders (numbers 2, 3, 4) and 2 control groups (numbers 1 and 5) of the present invention were tested for the migration, appearance and resolubility of colored substances. Or observe, what the test of resolubility all uses the physiological saline to carry out the dissolution test, and the result is shown in Table 2.

[0042] The lyophilized powder of No. 1, in terms of weight percentage, the lyophilized powder includes the following components: tripeptide-1 copper 0.5%, betaine 1%, trehalose 0.5%, mannitol 1%, deionized Water 97%.

[0043] The freeze-dried powder of No. 2, in terms of weight percentage, said freeze-dried powder includes the following components: tripeptide-1 copper 0.5%, betaine 1%,...

Embodiment 3

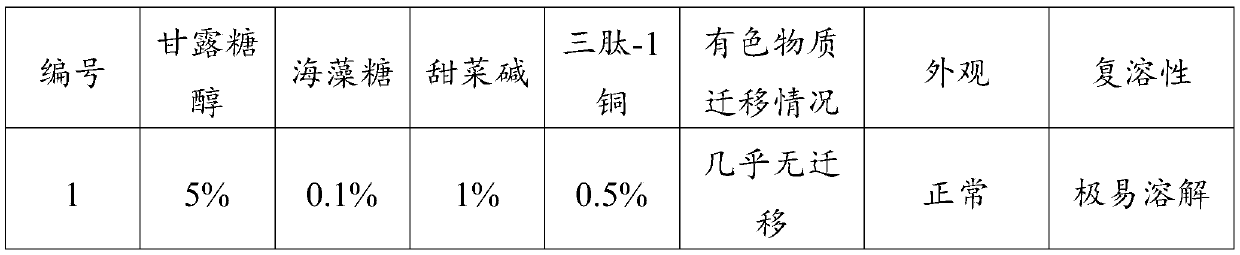

[0056] The purpose of this example is to compare the effects of the addition of trehalose and the concentration of tripeptide-1 copper itself on the migration of colored substance tripeptide-1 copper.

[0057] In this embodiment, 7 kinds of lyophilized powders (No. 1-7) of the present invention and 2 kinds of lyophilized powders of the control group (No. 8) were tested or observed on the migration of colored substances, appearance and resolubility. The solubility tests all used physiological saline for dissolution tests, and the results are shown in Table 3.

[0058] The freeze-dried powder of No. 1, in terms of weight percentage, said freeze-dried powder includes the following components: tripeptide-1 copper 0.5%, betaine 1%, trehalose 0.1%, mannitol 5%, deionized Water 93.4%.

[0059] The freeze-dried powder of No. 2, in terms of weight percentage, said freeze-dried powder includes the following components: tripeptide-1 copper 0.5%, betaine 1%, trehalose 0.8%, mannitol 5%, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com