Antibacterial and wound healing promotion composition and its medical hydrocolloid oil gauze

A wound healing and hydrocolloid technology, applied in the field of medical materials, can solve the problems of lack of cohesion and inability to remove the dressing as a whole, so as to broaden the range of antibacterial, promote Gram-positive bacteria, and inhibit Gram-negative bacteria Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

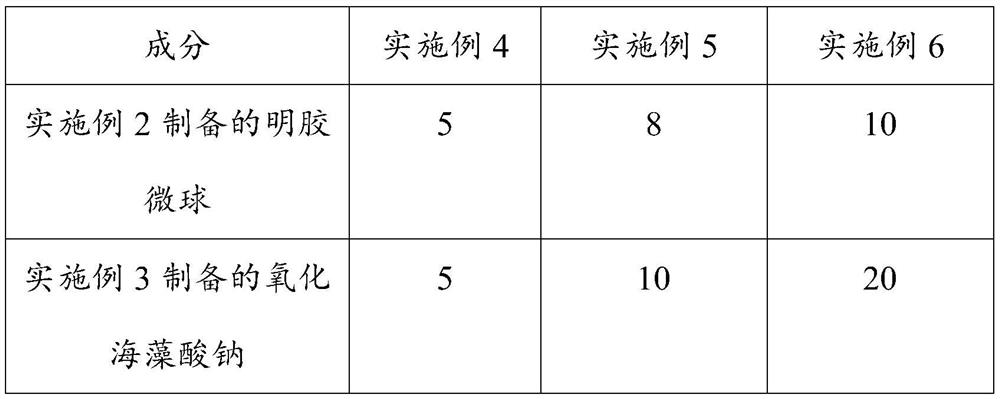

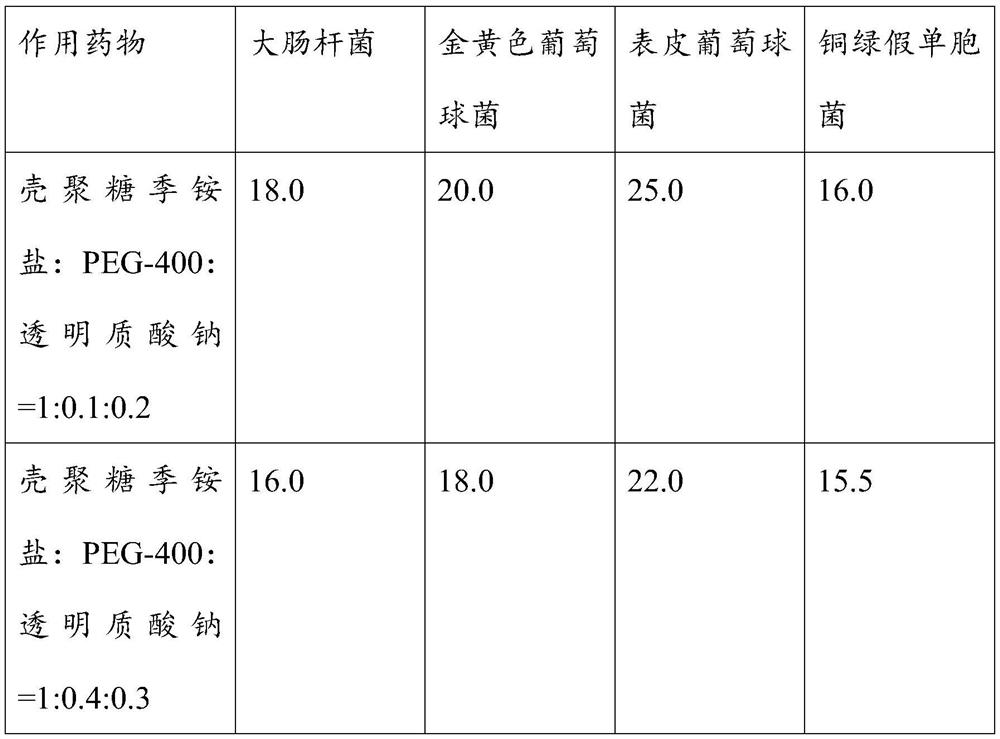

[0037] Embodiment 1, antibacterial and promote wound healing composition

[0038] group composition Composition 1 Chitosan quaternary ammonium salt: PEG-400: sodium hyaluronate = 1:0.1:0.2 Composition 2 Chitosan quaternary ammonium salt: PEG-400: sodium hyaluronate = 1:0.4:0.3 Composition 3 Chitosan quaternary ammonium salt: PEG-600: sodium hyaluronate = 1:0.6:0.4 Composition 4 Chitosan quaternary ammonium salt Composition 5 Sodium hyaluronate Composition 6 PEG-400 Composition 7 Chitosan quaternary ammonium salt: PEG-400=1:0.1

Embodiment 2

[0039] Embodiment 2, preparation of gelatin microspheres embedding antibacterial and promoting wound healing compositions

[0040] S1. Weigh gelatin and composition 1, add it into deionized water, stir at 60°C until completely dissolved, and obtain a solution with a concentration of 10%, which is used as the water phase;

[0041] S2. Add 60ml of vegetable oil into the beaker, then add 2ml of the mixture composed of Span 80 and Tween 80 in a mass ratio of 5:1 as an emulsifier, mix and preheat to 60°C, as the oil phase;

[0042] S3. Slowly add the water phase obtained in step S1 into the oil phase obtained in step S2. The volume ratio of the water phase to the oil phase is 1:5, mix evenly, and emulsify at a speed of 800r / min and a water bath temperature of 50°C 15min, a homogeneous emulsion was obtained;

[0043] S4. After emulsification, cool for 5 minutes, add 1 ml of glutaraldehyde solution with a concentration of 50% dropwise, and cross-link and solidify for 30 minutes to o...

Embodiment 3

[0045] Embodiment 3, preparation of oxidized sodium alginate

[0046] a. Sodium alginate is fully dissolved in pure water to obtain a 5wt% sodium alginate solution;

[0047] b. Slowly add the sodium periodate solution with a concentration of 0.5mol / L to the sodium alginate solution obtained in step a according to the volume ratio of 0.5:1. After reacting for 10 hours at room temperature in the dark, add 1ml of ethylene glycol to terminate the reaction. Stir for 1 hour to obtain oxidized sodium alginate solution;

[0048] c. Spray-dry the oxidized sodium alginate solution obtained in step b to obtain oxidized sodium alginate particles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com