Method for preparing adsorbent from high-alumina fly ash, and application of adsorbent

A high-alumina fly ash and adsorbent technology, applied in chemical instruments and methods, adsorbed water/sewage treatment, other chemical processes, etc., can solve the problems of adsorption effect, adsorption performance, high cost, easy to control the preparation process, The effect of low cost and simple process operation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1: This utilizes the method for preparing adsorbent with high aluminum fly ash, concrete steps are as follows:

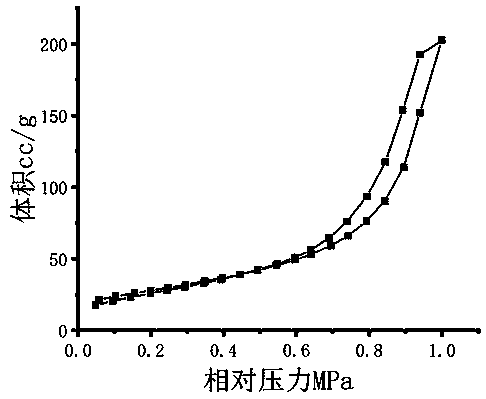

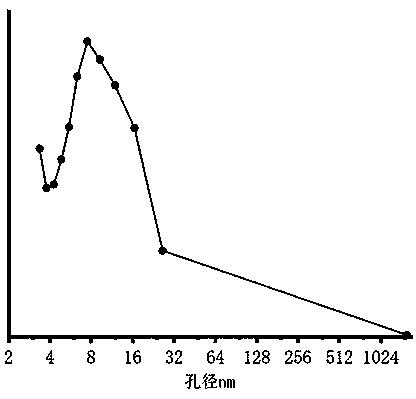

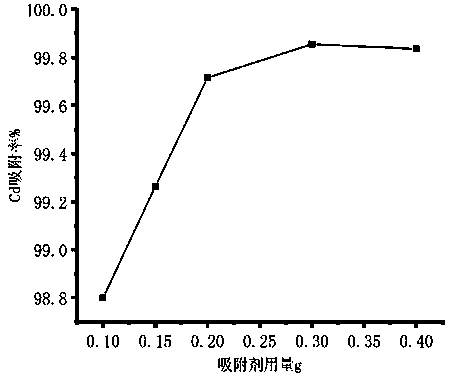

[0027] Put 50g of fly ash (Mongolian high-alumina fly ash) and 50g of anhydrous sodium carbonate into a crucible and mix evenly. After mixing, put the crucible into a box-type resistance furnace and raise the temperature to 900°C at a constant speed and react at a constant temperature for 120 minutes to obtain a sintered product. Sinter Cool the material to room temperature and grind it into powder; take 10g of powdery sintered material and put it into a conical flask, add a hydrochloric acid solution with a mass concentration of 18.5%, stir for 1 hour in a water bath at 90°C, filter with suction, and wash with distilled water until the filter residue is white , collect and combine the filtrate and washing liquid to prepare aluminum-containing solution, add distilled water and surfactant solution (polyether P123, the concentration of surfactant solu...

Embodiment 2

[0031] Embodiment 2: this utilizes the method for preparing adsorbent with high aluminum fly ash, concrete steps are as follows:

[0032] Put 50g of fly ash (Mongolian high-alumina fly ash) and 30g of anhydrous sodium carbonate into the crucible and mix evenly. After mixing, put the crucible into a box-type resistance furnace and raise the temperature to 1000°C at a constant speed and react at a constant temperature for 80 minutes to obtain a sintered product. Sinter The mixture was cooled to room temperature and ground into powder; 10 g of powdery sintered material was put into a conical flask, and a hydrochloric acid solution with a mass concentration of 15% was added, sealed with a plastic wrap, stirred for 1.5 h in a water bath at 70°C, and suction filtered. Wash with distilled water until the filter residue is white, collect and combine the filtrate and washing liquid to obtain an aluminum-containing solution, add distilled water and a surfactant solution (polyether P123, ...

Embodiment 3

[0034] Embodiment 3: this utilizes the method for preparing adsorbent with high aluminum fly ash, concrete steps are as follows:

[0035]Put 50g of fly ash (Mongolian high-alumina fly ash) and 60g of anhydrous sodium carbonate into the crucible and mix evenly. After mixing, put the crucible into a box-type resistance furnace and raise the temperature to 1200°C at a constant speed and react at a constant temperature for 60 minutes to obtain a sintered product. Sinter Cool the material to room temperature and grind it into powder; take 10g of powdered sintered material and put it into a conical flask, add a hydrochloric acid solution with a mass concentration of 25%, seal it with a plastic wrap, stir it in a water bath at 60°C for 2 hours, suction filter, distilled water Wash until the filter residue is white, collect and combine the filtrate and washing liquid to prepare an aluminum-containing solution, add distilled water and a surfactant solution (polyether P123, the concentra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com