Chromium-doped titanium oxygen cluster nano catalytic material, preparation method and applications thereof

A technology of nano-catalytic materials and titanium oxide clusters, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc., can solve the problem of poor quantum efficiency of photocatalysts and visible light absorption efficiency low cost, low detection limit and high degradation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The preparation method comprises the following steps:

[0029] Step 1: Mix and heat pivalic acid, tetrabutyl titanate and ethylene glycol to react to obtain titanyl cluster powder; the molar ratio of pivalic acid and tetrabutyl titanate is 1.8-2.2:1; the reaction temperature The temperature is 90~100℃, and the reaction time is 20~25h;

[0030] Step 2: adding titanyl cluster powder and chromium chloride to tetrabutyl titanate for ultrasonic dissolution, and reacting under boiling conditions to prepare chromium-doped titanyl cluster nanocatalytic material, the titanyl cluster powder and chromium chloride The mass ratio is 20:3.

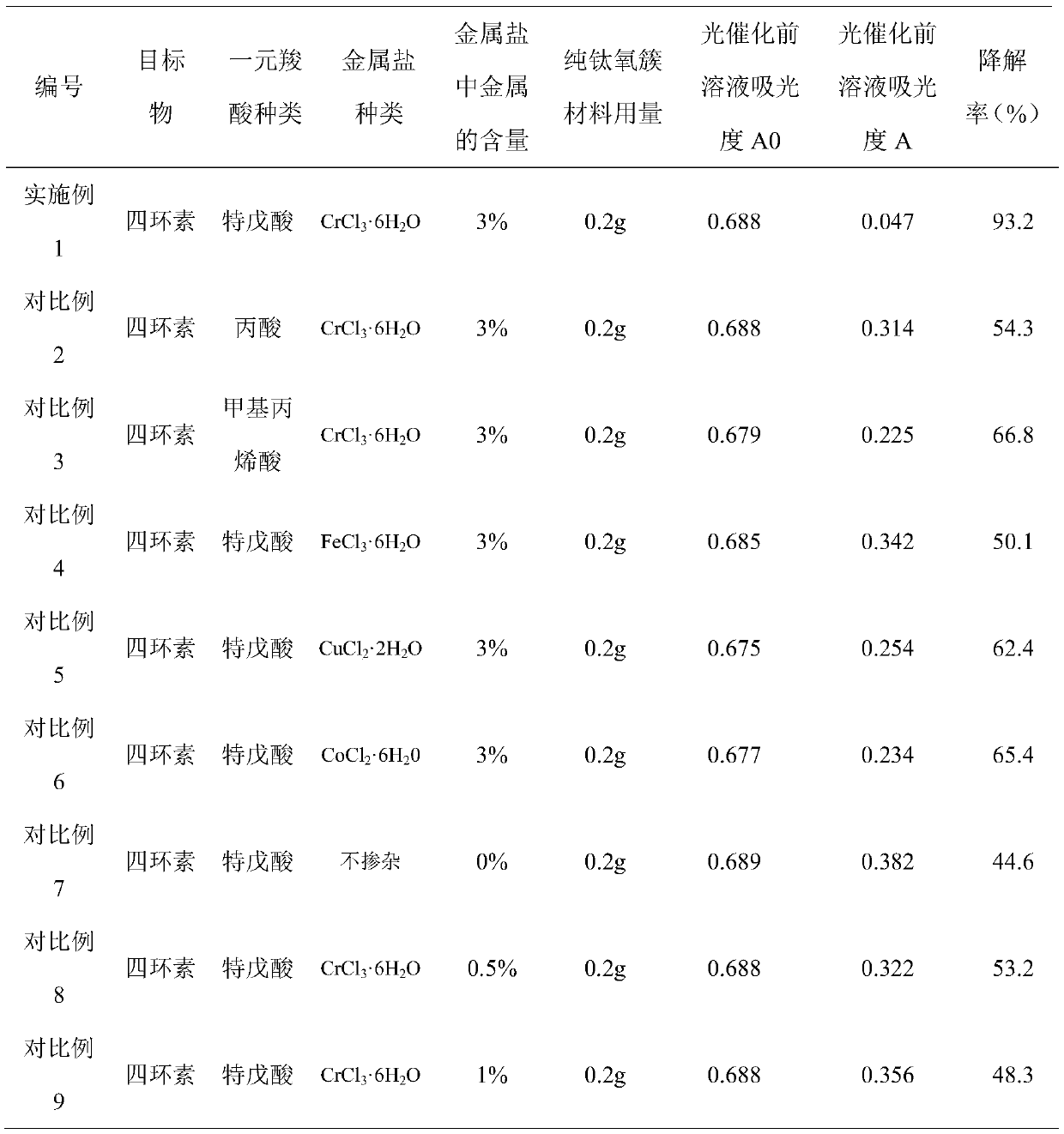

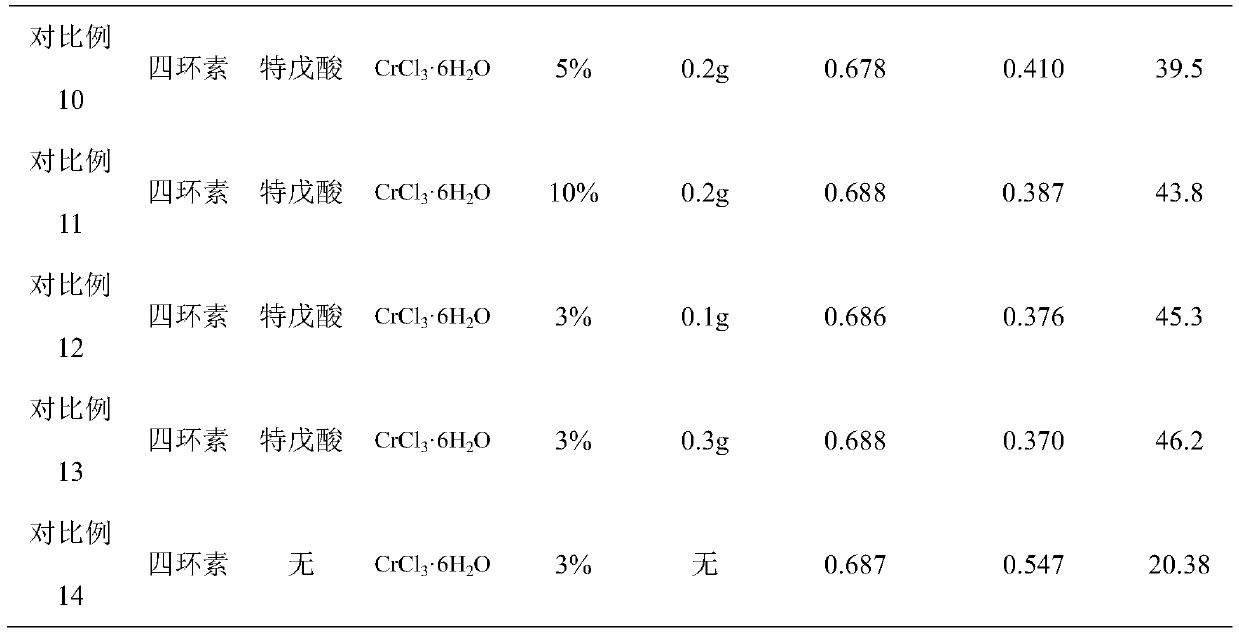

[0031] In order to check the degradation effect of the chromium-doped titania cluster nano-catalyst material prepared by the method of the present invention on tetracycline organic pollutants in water, the photocatalytic degradation experiment method is as follows: 0.010g of chromium-doped titania cluster nanocatalyst The material was added to ...

Embodiment 1

[0034] According to the above-mentioned technical scheme, this embodiment provides the chromium-doped titania cluster nano-catalyst material, its preparation method and its application. The monocarboxylic acid kind used in the present embodiment is pivalic acid (PA), and metal salt is chromium salt, and chromium chloride specifically comprises the following steps:

[0035] Step 1: Mix 10.5mmol PA with 5mmolTi(OBu) 4 Mix, add 20ml of ethylene glycol and stir for 5min to obtain a mixed solution, heat the mixed solution at 98°C for 24h; then wash with anhydrous tetrahydrofuran three times, centrifuge and dry at 65°C to obtain powdery solid particles , that is, pure titanium oxide cluster nanocatalytic materials;

[0036] Step 2: Weigh 0.2g of titanyl cluster powder obtained in Step 1 and 0.03g of chromium chloride into 10-20mL tetrabutyl titanate for ultrasonic dissolution. The ultrasonic time is 30 minutes, and then boiled for 60 minutes. Then, it is centrifuged with deionized...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com