Gold-copper-based brazing filler metal and welding method thereof

A welding method and solder technology, applied in welding medium, welding equipment, welding/cutting medium/material, etc., can solve the problems of difficult wetting of solder and large residual stress of brazing joints, so as to prevent crack propagation and improve Wetting condition, effect of high normal/high temperature shear strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

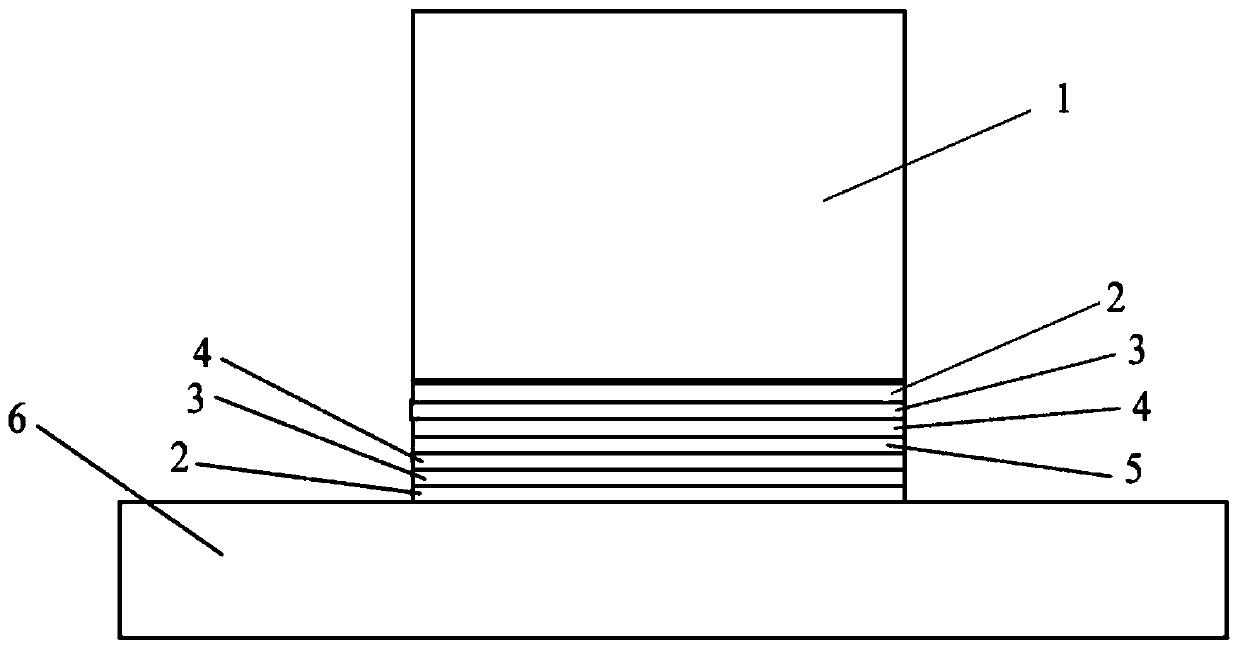

[0041] A gold-copper-based solder, specifically a composite solder of Au-Cu-Ti-B / Mo / Au-Cu-Ti-B, consisting of Au foil, Cu foil, Mo foil and paste solder, The mass ratio of Au foil, Cu foil and Mo foil is Au:Cu:Mo=197:64:96, the paste solder is a mixture of TiB powder and binder, and the mass ratio of TiB powder and binder is TiB powder : adhesive=1:0.5, described TiB powder is prepared by TiH powder and B powder, and TiH powder and B powder mass ratio are TiH:B=142:1;

[0042] The purity of the described Au foil, Cu foil and Mo foil is above 99%;

[0043] The thickness of the Mo foil is 50 μm;

[0044] The thickness of the Au foil is 50 μm;

[0045] The thickness of the Cu foil is 50 μm;

[0046] The thickness of the paste solder is 15 μm;

[0047] The particle size of described TiH powder, B powder is 300 mesh, and purity is more than 99%;

[0048] Described bonding agent is the mixture of terpineol and dehydrated alcohol, and the volume ratio of terpineol and dehydrated...

Embodiment 2

[0065] A gold-copper-based solder, specifically a composite solder of Au-Cu-Ti-B / Mo / Au-Cu-Ti-B, consisting of Au foil, Cu foil, Mo foil and paste solder, The mass ratio of Au foil, Cu foil and Mo foil is Au:Cu:Mo=197:64:100, the paste solder is a mixture of TiB powder and binder, and the mass ratio of TiB powder and binder is TiB powder : adhesive=1:0.2, described TiB powder is prepared by TiH powder and B powder, and TiH powder and B powder mass ratio are TiH:B=17.6:1;

[0066] The purity of the described Au foil, Cu foil and Mo foil is above 99%;

[0067] The thickness of the Mo foil is 52 μm;

[0068] The thickness of the Au foil is 50 μm;

[0069] The thickness of the Cu foil is 50 μm;

[0070] The thickness of the paste solder is 20 μm;

[0071] The particle size of described TiH powder, B powder is 300 mesh, and purity is more than 99%;

[0072] Described binding agent is the mixture of terpineol and dehydrated alcohol, and the volume ratio of terpineol and dehydrat...

Embodiment 3

[0089] A gold-copper-based solder, specifically a composite solder of Au-Cu-Ti-B / Mo / Au-Cu-Ti-B, consisting of Au foil, Cu foil, Mo foil and paste solder, The mass ratio of Au foil, Cu foil and Mo foil is Au:Cu:Mo=196:63:115, the paste solder is a mixture of TiB powder and binder, and the mass ratio of TiB powder and binder is TiB powder : adhesive=1:0.3, described TiB powder is prepared by TiH powder and B powder, and TiH powder and B powder mass ratio are TiH:B=48:1;

[0090] The purity of the described Au foil, Cu foil and Mo foil is above 99%;

[0091] The thickness of the Mo foil is 60 μm;

[0092] The thickness of the Au foil is 50 μm;

[0093] The thickness of the Cu foil is 50 μm;

[0094] The thickness of the paste solder is 15 μm;

[0095] The particle size of described TiH powder, B powder is 300 mesh, and purity is more than 99%;

[0096] Described bonding agent is the mixture of terpineol and dehydrated alcohol, and the volume ratio of terpineol and dehydrated a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com