Preparation method of salt ion-tolerant block copolymer latex

A technology of block copolymers and ions, applied in the field of preparation of block copolymer latex, to achieve the effects of environmental friendliness, fast reaction speed, and simplified process equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

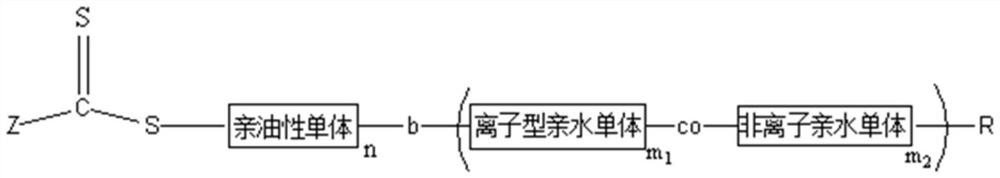

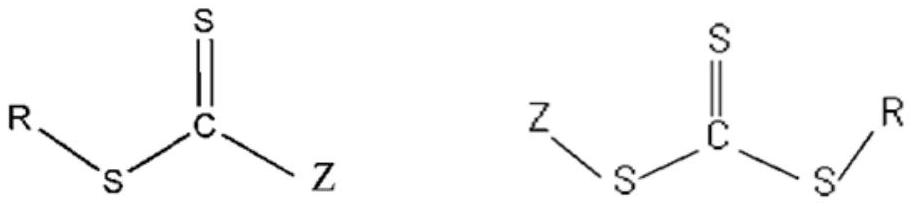

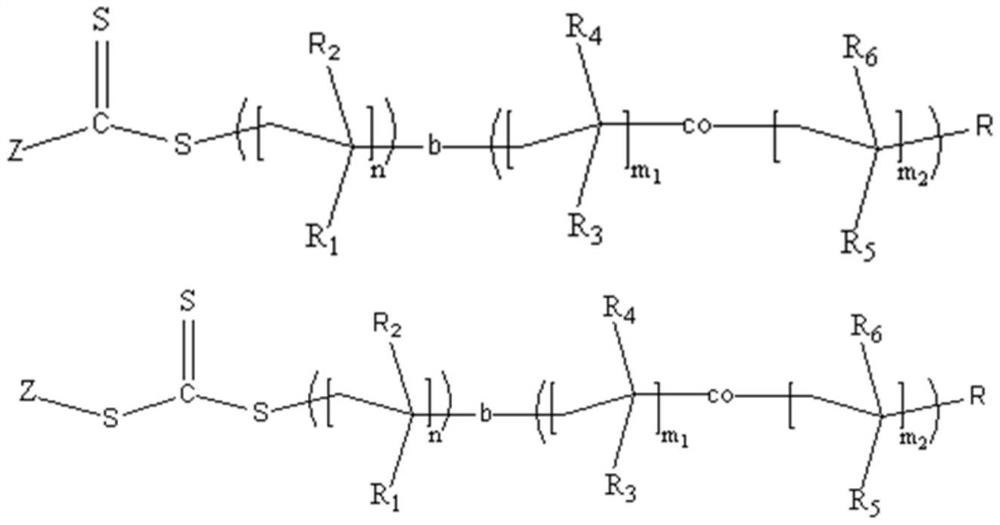

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] 40 grams of water, 0.7 grams of amphiphilic macromolecular reversible addition chain scission chain transfer reagent (1), and 1 gram of styrene were added to the reactor, stirred and mixed, stirred, nitrogen gas was passed for 30 minutes, and the temperature was raised to 70 ° C. Add 0.01 gram of potassium persulfate to initiate polymerization, add an aqueous solution containing 0.2 gram of sodium hydroxide when reacting to 10 minutes, add 20 grams of butyl acrylate when reacting to 60 minutes, and then continue to polymerize for 2 hours to obtain salt-resistant intercalated segment copolymer latex.

Embodiment 2

[0039] Add 40 grams of water, 0.7 grams of amphiphilic macromolecular reversible addition chain scission chain transfer reagent (2), and 1 gram of styrene into the reactor, stir and mix, stir, nitrogen gas for 30 minutes, and heat up to 70 ° C. Add 0.01 gram of potassium persulfate to initiate polymerization, add an aqueous solution containing 0.2 gram of sodium hydroxide when reacting to 10 minutes, add 20 grams of butyl acrylate when reacting to 30 minutes, and then continue to polymerize for 2 hours to obtain salt-resistant intercalated segment copolymer latex.

Embodiment 3

[0041] 40 grams of water, 0.4 grams of amphiphilic macromolecular reversible addition chain scission chain transfer reagent (3), and 20 grams of styrene were added to the reactor, stirred and mixed, stirred, nitrogen gas was passed for 30 minutes, and the temperature was raised to 70 ° C. Add 0.006 gram of potassium persulfate to initiate polymerization, add 0.1 gram of sodium hydroxide aqueous solution when reacting to 30 minutes, add 1 gram of butyl acrylate when reacting to 120 minutes, and then continue to polymerize for 30 minutes to obtain salt ion intercalated segment copolymer latex.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com