Foam fireproof material suitable for charging station

A technology of fireproof materials and charging stations, applied in the field of foam fireproof materials, can solve the problems of foam plastics with limited flame retardancy and fireproof effects, achieve enhanced structural toughness and heat resistance, excellent impact toughness and electrical insulation, and improve compactness degree and effect of homeostasis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

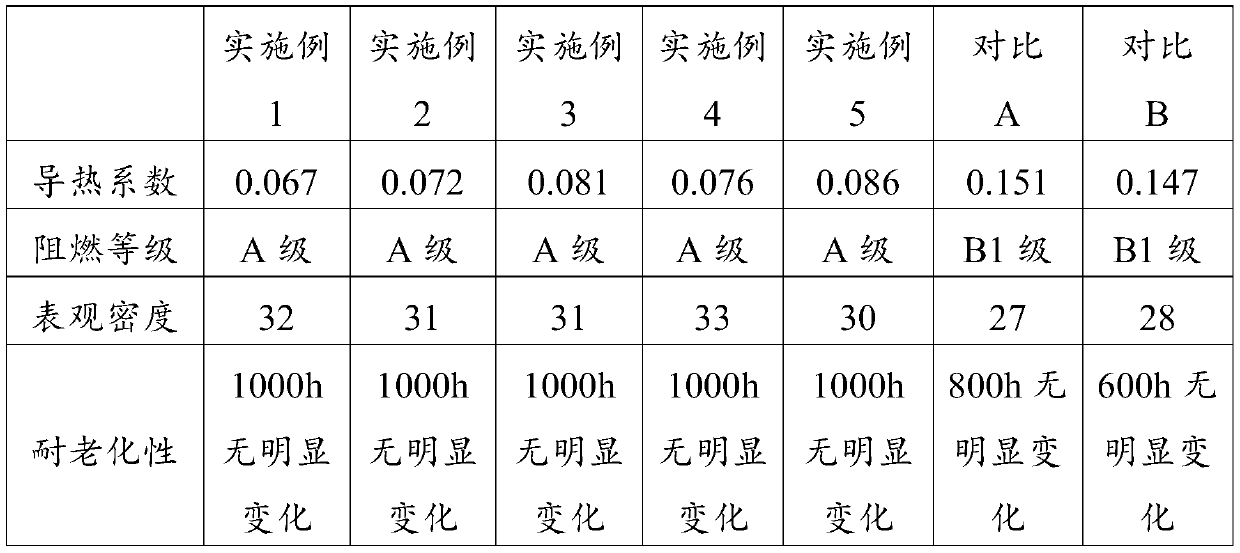

Examples

Embodiment 1

[0022] A foam fireproof material suitable for charging stations, wherein the raw material components are by weight: 6 parts of foaming agent, 7 parts of foam stabilizer, 10 parts of water-based adhesive, 11 parts of coupling agent, 4 parts of glass fiber, 4 parts of limestone, 18 parts of isocyanate, 35 parts of polyvinyl chloride resin and 10 parts of flame retardant.

[0023] Specifically, the preparation method includes the following steps:

[0024] S1: Add glass fiber, isocyanate and flame retardant together into the mixer, and stir and mix at a speed of 140r / min for 0.5h to obtain mixture A;

[0025] S2: Add polyvinyl chloride resin, limestone, water-based binder and an appropriate amount of water into the reaction kettle, heat up to 160°C and stir and blend for 0.5h to obtain reaction sol B;

[0026] S3: Put the mixture A, reaction sol B, coupling agent, foam stabilizer, and foaming agent into the mold after uniform mixing, and then perform foaming treatment in the foam...

Embodiment 2

[0035] A foam fireproof material suitable for charging stations, wherein the raw material components are calculated by weight: 6 parts of foaming agent, 7 parts of foam stabilizer, 6 parts of water-based adhesive, 8 parts of coupling agent, 10 parts of glass fiber, 5 parts of limestone, 18 parts of isocyanate, 30 parts of polyvinyl chloride resin and 7 parts of flame retardant.

[0036] Specifically, the preparation method includes the following steps:

[0037] S1: Add glass fiber, isocyanate and flame retardant together into the mixer, and stir and mix at a speed of 120r / min for 0.5h to obtain mixture A;

[0038] S2: Add polyvinyl chloride resin, limestone, water-based binder and an appropriate amount of water into the reaction kettle, heat up to 160°C and stir and blend for 1 hour to obtain reaction sol B;

[0039] S3: Put the mixture A, reaction sol B, coupling agent, foam stabilizer, and foaming agent into the mold after uniform mixing, and then perform foaming treatment ...

Embodiment 3

[0048] A foam fireproof material suitable for charging stations, wherein the raw material components are by weight: 8 parts of foaming agent, 7 parts of foam stabilizer, 10 parts of water-based adhesive, 11 parts of coupling agent, 8 parts of glass fiber, 4 parts of limestone, 18 parts of isocyanate, 35 parts of polyvinyl chloride resin and 7 parts of flame retardant.

[0049] Specifically, the preparation method includes the following steps:

[0050] S1: Add glass fiber, isocyanate and flame retardant together into the mixer, and stir and mix at a speed of 130r / min for 0.5h to obtain mixture A;

[0051] S2: Add polyvinyl chloride resin, limestone, water-based binder and an appropriate amount of water into the reaction kettle, heat up to 160°C and stir and blend for 0.5h to obtain reaction sol B;

[0052]S3: Put the mixture A, reaction sol B, coupling agent, foam stabilizer, and foaming agent into the mold after uniform mixing, and then perform foaming treatment in the foamin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com