Anti-sagging thermal-insulation self-cleaning coating for building external wall and preparation method thereof

An anti-sagging technology for building exterior walls, applied in antifouling/underwater coatings, coatings, paints containing biocides, etc., can solve the problems of small effective production volume, high requirements for production equipment, troublesome production operations, etc. Achieve the effect of improving structural connection stability, improving mechanical properties and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

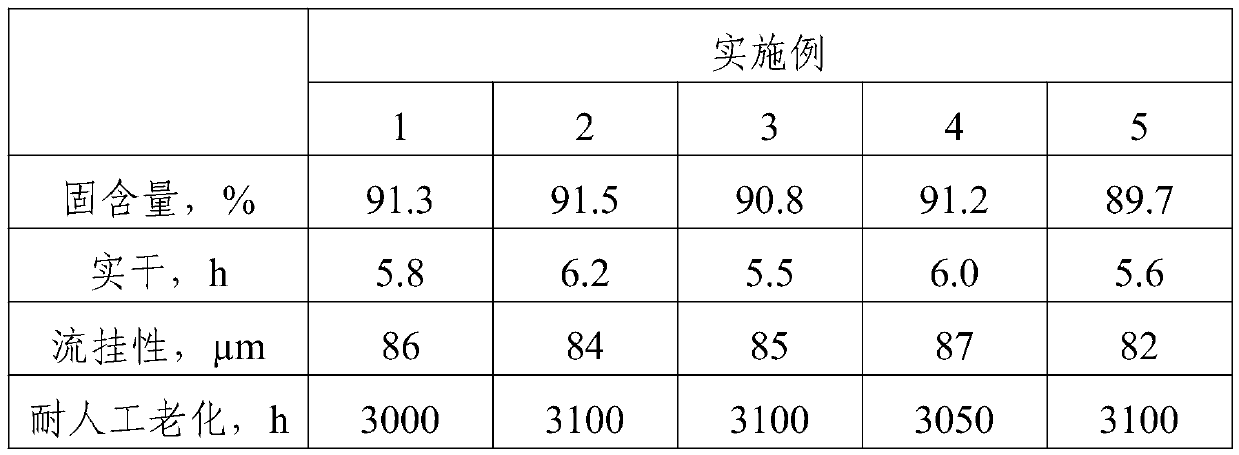

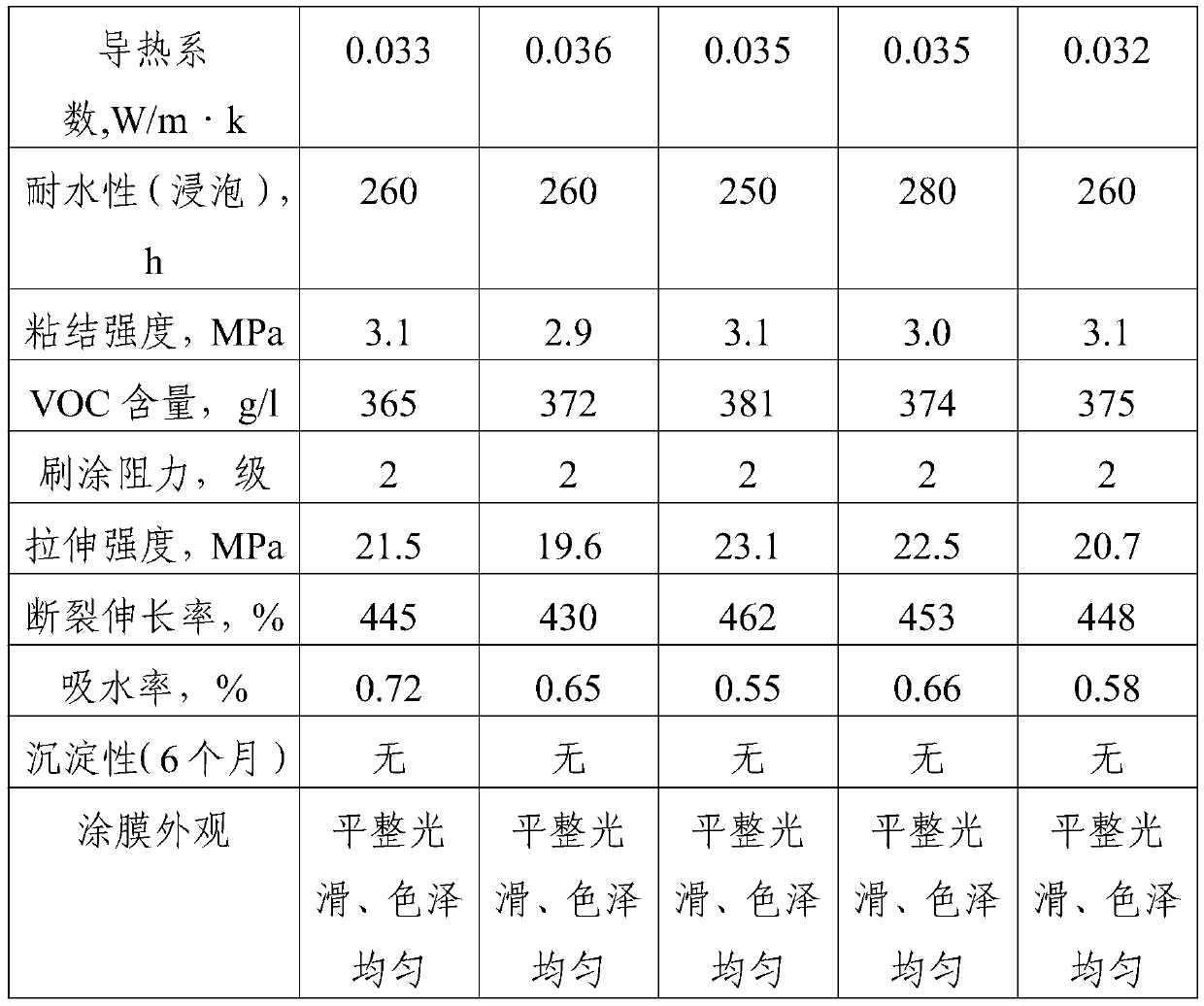

Examples

Embodiment 1

[0026] An anti-sag heat preservation self-cleaning coating for building exterior walls, comprising the following parts by weight: 60 parts of silicone acrylic emulsion, 40 parts of elastic emulsion, 15 parts of polyacrylamide, 6 parts of prefabricated fiber coating material, sodium humate 4 parts, 4 parts of expanded vermiculite, 10 parts of filler, 4 parts of additives, 10 parts of water.

[0027] in:

[0028] The prefabricated fiber covering material includes the following components in mass percentage: 10% of polyamide short fiber, 30% of nano silicon oxide, 4% of nano zinc oxide, 0.8% of hydrogenated polydimethylsiloxane, 0.4% of cocoamide monoethanolamine %, polyethylene glycol solution balance.

[0029] The preparation method of the prefabricated fiber covering material is as follows: add short polyamide fibers into an appropriate amount of polyethylene glycol solution, heat and stir at 45-50°C for 2 hours, then add cocoamide monoethanolamine, and continue stirring for ...

Embodiment 2

[0038] An anti-sagging, thermal insulation and self-cleaning coating for building exterior walls, comprising the following parts by weight: 80 parts of silicone acrylic emulsion, 50 parts of elastic emulsion, 20 parts of polyacrylamide, 10 parts of prefabricated fiber coating material, sodium humate 6 parts, expanded vermiculite 5 parts, filler 15 parts, additives 4 parts, water 20 parts.

[0039] in:

[0040] The prefabricated fiber covering material includes the following components in mass percentage: 15% of polyamide short fiber, 25% of nano silicon oxide, 2% of nano zinc oxide, 1.2% of hydrogenated polydimethylsiloxane, 0.8% of cocoamide monoethanolamine %, polyethylene glycol solution balance.

[0041] The preparation method of the prefabricated fiber covering material is as follows: add short polyamide fibers into an appropriate amount of polyethylene glycol solution, heat and stir at 45-50°C for 1.5 hours, then add cocoamide monoethanolamine into it, and continue stir...

Embodiment 3

[0046] An anti-sag heat preservation self-cleaning coating for building exterior walls, comprising the following parts by weight: 100 parts of silicone acrylic emulsion, 50 parts of elastic emulsion, 15 parts of polyacrylamide, 15 parts of prefabricated fiber coating material, sodium humate 6 parts, 3 parts of expanded vermiculite, 20 parts of filler, 3 parts of auxiliary agent, 30 parts of water.

[0047] in:

[0048] The prefabricated fiber covering material includes the following components in mass percentage: polyamide short fiber 15%, nano silicon oxide 20%, nano zinc oxide 1%, hydrogenated polydimethylsiloxane 0.8%, cocoamide monoethanolamine 0.3 %, polyethylene glycol solution balance.

[0049] The preparation method of the prefabricated fiber covering material is as follows: add short polyamide fibers into an appropriate amount of polyethylene glycol solution, heat and stir at 45-50°C for 1 hour, then add cocoamide monoethanolamine, and continue stirring for 50 minute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com