A kind of preparation method of tungsten carbide-nickel carbide

A cemented carbide, tungsten carbide technology, used in metal processing equipment, transportation and packaging, coating, etc., can solve the problems of non-dense products, poor performance, and many impurities, and achieve high repeatability, simple operation, and packaging. Even coverage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

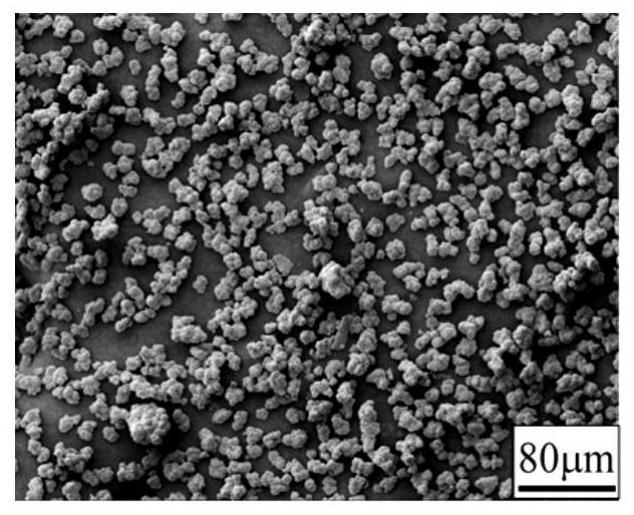

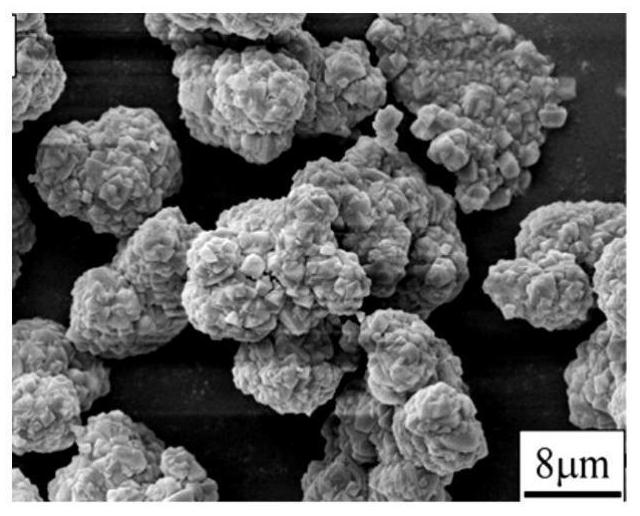

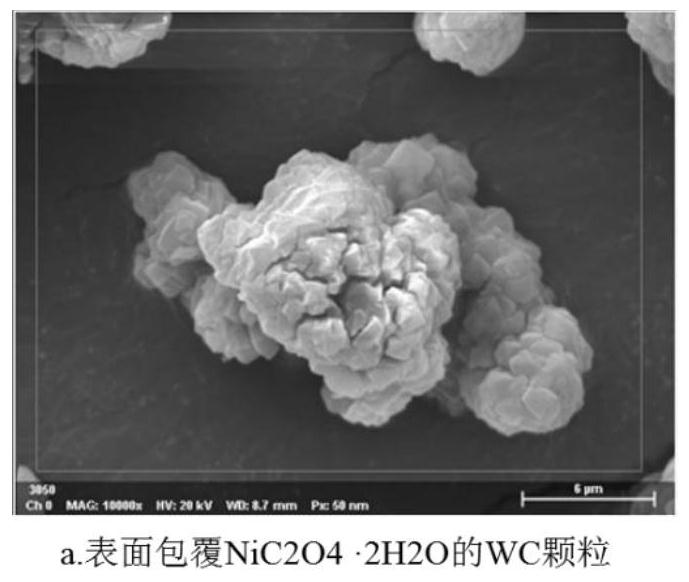

[0026] Take 50g of tungsten carbide powder with an average particle size of 5.0 μm and a purity of 99.9%, place it in 500ml of hydrofluoric acid-nitric acid mixed aqueous solution and carry out coarsening treatment under mechanical stirring. The concentration of hydrofluoric acid is 30ml / L, and the concentration of nitric acid is 30ml / L, the stirring time is 30min, after stirring, soak for 20min, then filter and dry the powder. Get 19.06g of solid granular medicine NiCl at the same time 2 ·6H 2 O is added to deionized water to configure a concentration of 0.4mol / LNiCl 2 Solution 200ml, take 5.68g solid granule medicine (NH 4 ) 2 C 2 o 4 ·H 2 O was added to deionized water to configure a concentration of 0.2mol / L (NH 4 ) 2 C 2 o 4 The solution was 200ml, and the two solutions were heated to 50°C in a water bath at the same time. Then take 21.2g of roughened tungsten carbide powder and pour it into the heated NiCl 2 solution, after mechanical stirring for 20min, the ...

Embodiment 2

[0037] Take 50g of tungsten carbide powder with an average particle size of 5.0 μm and a purity of 99.9%, place it in 500ml of hydrofluoric acid-nitric acid mixed aqueous solution and carry out coarsening treatment under mechanical stirring. The concentration of hydrofluoric acid is 30ml / L, and the concentration of nitric acid is 30ml / L, the stirring time is 30min, after stirring, soak for 20min, then filter and dry the powder. Get 19.06g of solid granular medicine NiCl at the same time 2 ·6H 2 O is added to deionized water to configure a concentration of 0.4mol / LNiCl 2 Solution 200ml, take 5.68g solid granule medicine (NH 4 ) 2 C 2 o 4 ·H 2 O was added to deionized water to configure a concentration of 0.2mol / L (NH 4 ) 2 C 2 o 4 The solution was 200ml, and the two solutions were heated to 65°C in a water bath at the same time. Then take 21.2g of roughened tungsten carbide powder and pour it into the heated NiCl 2 solution, after mechanical stirring for 20min, the ...

Embodiment 3

[0040] Take 50g of tungsten carbide powder with an average particle size of 5.0 μm and a purity of 99.9%, place it in 500ml of hydrofluoric acid-nitric acid mixed aqueous solution and carry out coarsening treatment under mechanical stirring. The concentration of hydrofluoric acid is 30ml / L, and the concentration of nitric acid is 30ml / L, the stirring time is 30min, after stirring, soak for 20min, then filter and dry the powder. Get 19.06g of solid granular medicine NiCl at the same time 2 ·6H 2 O is added to deionized water to configure a concentration of 0.4mol / LNiCl 2 Solution 200ml, take 5.68g solid granule medicine (NH 4 ) 2 C 2 o 4 ·H 2 O was added to deionized water to configure a concentration of 0.2mol / L (NH 4 ) 2 C 2 o 4 Solution 200ml, and the two solutions were heated to 35 ° C in a water bath at the same time. Then take 21.2g of roughened tungsten carbide powder and pour it into the heated NiCl 2 solution, after mechanical stirring for 20min, the NiCl ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com