Accelerant for titanium powder mechanochemical deposition and application

A mechanochemical and accelerator technology, which is applied in the field of titanium plating on steel substrates and surface protection, can solve the problems that metal titanium cannot be electroplated, and achieve the effect of clean surface, chemical stability, and stable deposition process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

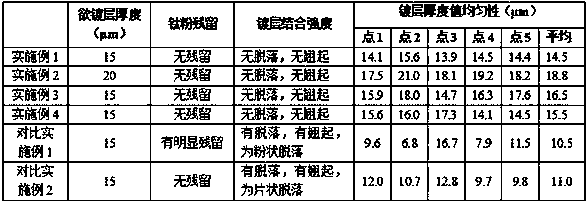

Embodiment 1

[0027] The components and their mass percentages of the titanium powder mechanochemical deposition accelerator described in this example are:

[0028] Ammonium bifluoride 10%

[0030] Polyethylene glycol 4000 6%

[0031] Nickel Sulfamate 5%

[0032] OP-10 8%

[0033] Sodium Hypophosphite 2%

[0034] Industrial concentrated sulfuric acid 3%

[0035] water balance

[0036] The components of the accelerator for mechanochemical deposition of titanium powder are all industrial grade chemical raw materials. After weighing according to the above mass percentage, first add water and industrial concentrated sulfuric acid to the container, then add ammonium bifluoride, zinc sulfate, sulfamic acid Nickel, polyethylene glycol and OP-10 are mixed evenly and the preparation is completed. It is recommended to use up the above-mentioned accelerators within 8 hours.

[0037] The accelerator for mechanochemical deposition of titanium powder described in this exam...

Embodiment 2

[0043] The components and their mass percentages of the titanium powder mechanochemical deposition accelerator described in this example are:

[0044] Ammonium bifluoride 25%

[0045] Zinc sulfate 12%

[0046] Polyethylene glycol 8000 15%

[0047] Nickel Sulfamate 8%

[0048] TX-10 3%

[0049] Sodium Hypophosphite 5%

[0050] Hydrofluoric acid 0.5%

[0051] water balance

[0052] The components of the accelerator for mechanochemical deposition of titanium powder are all industrial-grade chemical raw materials. After weighing according to the above mass percentage, first add water and hydrofluoric acid to the container, then add ammonium bifluoride, zinc sulfate, sulfamic acid Nickel, polyethylene glycol, TX-10, stir evenly and the preparation is complete. It is recommended to use up the above-mentioned accelerators within 8 hours.

[0053]The accelerator for mechanochemical deposition of titanium powder described in this example is used for the mechanochemical depositio...

Embodiment 3

[0060] The components and their mass percentages of the titanium powder mechanochemical deposition accelerator described in this example are:

[0061] Ammonium bifluoride 20%

[0062] Zinc sulfate 10%

[0063] Polyethylene glycol 4000 8%

[0064] Nickel Sulfamate 3%

[0065] OP-10 6%

[0066] Sodium Hypophosphite 3%

[0067] Industrial concentrated sulfuric acid 6%

[0068] water balance

[0069] The components of the accelerator for mechanochemical deposition of titanium powder are all industrial grade chemical raw materials. After weighing according to the above mass percentage, first add water and industrial concentrated sulfuric acid to the container, then add ammonium bifluoride, zinc sulfate, sulfamic acid Nickel, polyethylene glycol and OP-10 are mixed evenly and the preparation is completed. It is recommended to use up the above-mentioned accelerators within 8 hours.

[0070] The accelerator for mechanochemical deposition of titanium powder described in this exa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com