Preparation method of Ti-doped internal tin method Nb3Sn precursor wire

A technology of precursor and internal tin method is applied in the field of preparation of Ti-doped internal tin method Nb3Sn precursor wire, which can solve the problems of easy disconnection, poor plastic workability, etc. The effect of reducing the processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A kind of Ti-doped inner tin method Nb 3 The preparation method of Sn precursor wire rod specifically comprises the following steps:

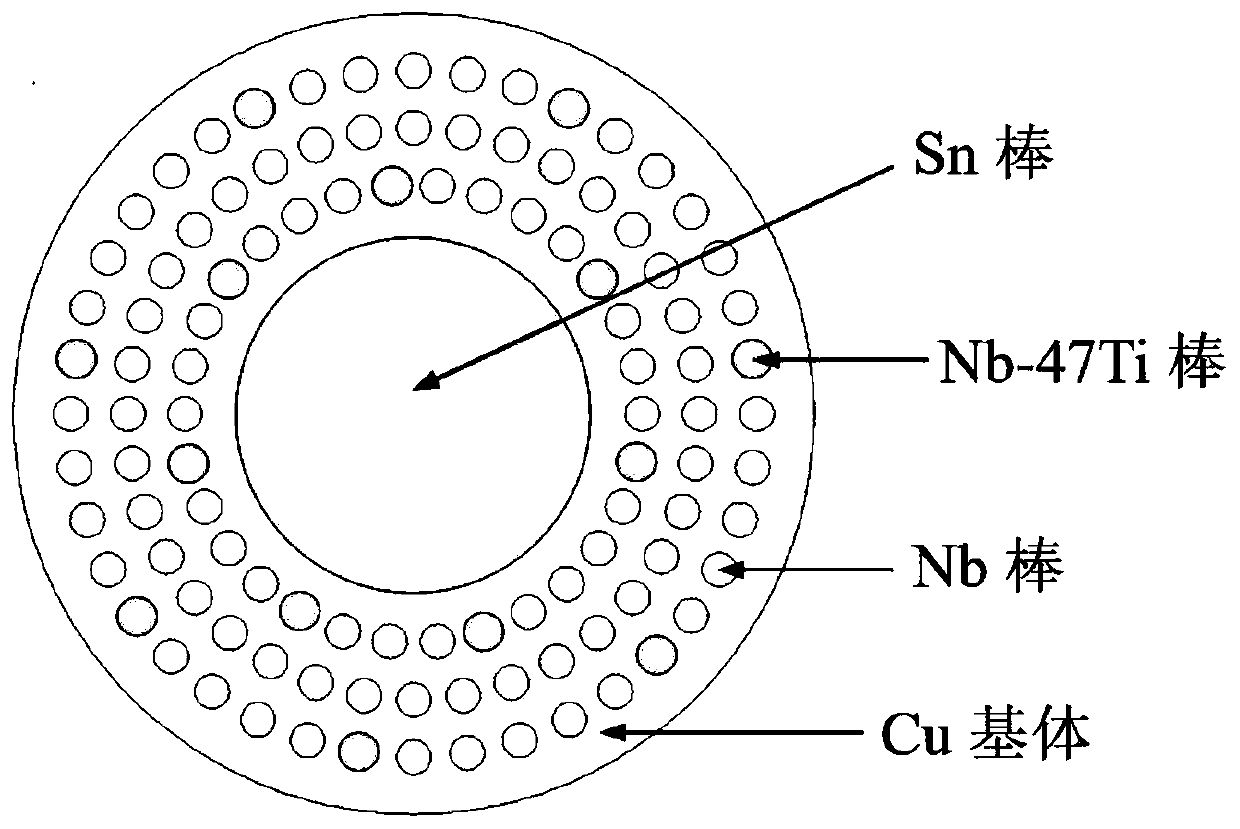

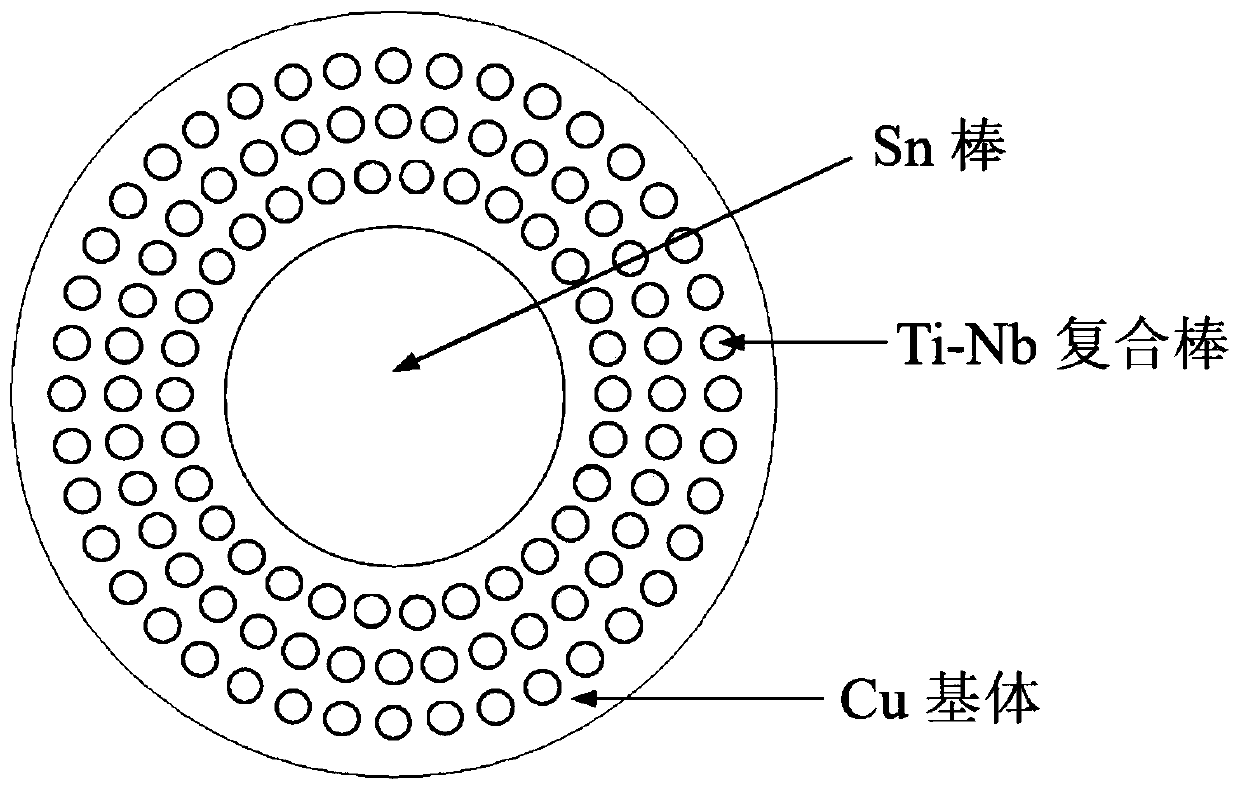

[0026] (1) Make a composite rod: Insert a Nb rod with a length of 300 mm and a diameter of 9.8 mm into a Nb-1 wt.% Ti alloy tube with the same length, an outer diameter of 11.8 mm, and a wall thickness of 1.0 mm, and then insert the obtained Nb- The Ti / Nb composite rod is inserted into a hexagonal Cu tube with an inner diameter of 12mm and a distance across sides of H15 mm to form a Cu / Nb-Ti / Nb composite rod;

[0027] (2) Sheath assembly: put 30 Cu / Nb-Ti / Nb composite rods and 7 central Cu rods of the same size above into the copper sheath containing the Nb barrier layer in the closest arrangement, and the copper sheath The inner diameter of the tube is 120 mm, the wall thickness is 15 mm, and the length is 300 mm; then it is sealed by vacuum electron beam welding to obtain (30+7) core Cu-Nb composite cladding blank;

[0028] (3) Making...

Embodiment 2

[0033] A kind of Ti-doped inner tin method Nb 3 The preparation method of Sn precursor wire rod specifically comprises the following steps:

[0034] (1) Make a composite rod: Insert a Nb rod with a length of 450 mm and a diameter of 9.8 mm into a Nb-1 wt.% Ti alloy tube with the same length, an outer diameter of 11.8 mm, and a wall thickness of 1.0 mm, and then insert the obtained Nb- The Ti / Nb composite rod is inserted into a hexagonal Cu tube with an inner diameter of 12mm and a distance across sides of H15 mm to form a Cu / Nb-Ti / Nb composite rod;

[0035](2) Packing assembly: put 90 Cu / Nb-Ti / Nb composite rods and 37 central Cu rods of the same size above into the copper sheath containing the Ta barrier layer according to the closest arrangement, and the copper sheath The inner diameter of the tube is 195 mm, the wall thickness is 15 mm, and the length is 450 mm; then it is sealed by vacuum electron beam welding to obtain (90+37) core Cu-Nb composite cladding blank;

[0036...

Embodiment 3

[0041] A kind of Ti-doped inner tin method Nb 3 The preparation method of Sn precursor wire rod specifically comprises the following steps:

[0042] (1) Make a composite rod: Insert a Nb rod with a length of 400 mm and a diameter of 5.8 mm into a Nb-5 wt.% Ti alloy tube with the same length, an outer diameter of 6.8 mm, and a wall thickness of 0.5 mm, and then insert the obtained Nb- The Ti / Nb composite rod is inserted into a hexagonal Cu tube with an inner diameter of 7 mm and a distance across sides of H8.5 mm to form a Cu / Nb-Ti / Nb composite rod;

[0043] (2) Packing assembly: put 159 Cu / Nb-Ti / Nb composite rods and 61 central Cu rods of the same size above into the copper sheath containing the Ta barrier layer in the most dense arrangement, and the copper sheath The inner diameter of the tube is 160 mm, the wall thickness is 15 mm, and the length is 450 mm; then it is sealed by vacuum electron beam welding to obtain (159+61) core Cu-Nb composite cladding blank;

[0044] (3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current density | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com