Steel-plastic high flame-retardant fireproof door and window profiles and manufacturing method thereof

A door and window profile, high flame-retardant technology, applied in the direction of window/door frame, leaf frame, etc., can solve the problems of large amount of addition, difficult to eliminate impurities, affect compatibility, etc., to achieve improved impact strength and plasticity, improve Flame retardant and smoke suppression efficiency, fire integrity improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

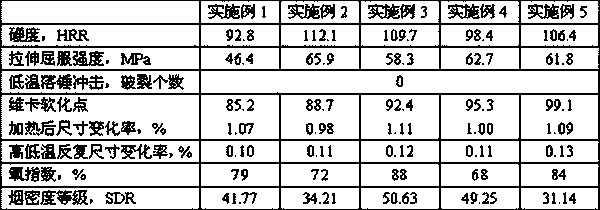

Examples

Embodiment 1

[0032] Preparation of flame retardant and smoke suppressant: The material ratio is 37.5wt% of zinc stannate, 45.8wt% of α-ammonium octamolybdate, 12.2wt% of α-zirconium phosphate, 3wt% of methylamine aqueous solution with a concentration of 25wt%, cetyl Tributyl phosphorus bromide 1.5wt%.

[0033] First mix α-zirconium phosphate and methylamine aqueous solution, after 100mW ultrasonic treatment for 30min, add hexadecyl tributyl phosphorus bromide, continue 100mW ultrasonic treatment for 30min, centrifugal filter, rinse with water until AgNO 3 Aqueous solution test washing liquid without Br - In the presence of, at 65°C, 2 x 10 4 Vacuum-dried at Pa pressure for 10 hours, ground through a 200-mesh sieve, mixed with zinc stannate and α-ammonium octamolybdate, put into a high-frequency resonance grinder, and ground and mixed for 12 hours to obtain a flame retardant and smoke suppressant.

[0034] PVC foam: PVC resin 70wt%, XT-1 heat stabilizer 1.5wt%, synthetic vegetable ester p...

Embodiment 2

[0038] Preparation of flame retardant and smoke suppressant: The material ratio is 44.4wt% of zinc stannate, 37wt% of α-ammonium octamolybdate, 13.5wt% of α-zirconium phosphate, 3.4wt% of methylamine aqueous solution with a concentration of 25wt%, cetyl Tributyl phosphorus bromide 1.7wt%. Processing method is identical with embodiment 1.

[0039] PVC foam: PVC resin 68wt%, XT-1 heat stabilizer 2wt%, synthetic vegetable ester plasticizer 12wt%, ACR processing modifier 2.5wt%, PE wax 1wt%, UV-327 ultraviolet absorber 0.5wt %, titanium dioxide 3wt%, flame retardant and smoke suppressant 10wt%, AC blowing agent 1wt%.

[0040] The PVC foam mixing method and the steel-plastic composite method are the same as in Example 1.

Embodiment 3

[0042] Preparation of flame retardant and smoke suppressant: The material ratio is 41.7wt% of zinc stannate, 44.5wt% of α-ammonium octamolybdate, 10wt% of α-zirconium phosphate, 2.5wt% of methylamine aqueous solution with a concentration of 25wt%, cetyl Tributyl phosphorus bromide 1.3wt%; Processing method is identical with embodiment 1.

[0043] PVC foam: PVC resin 62wt%, XT-1 heat stabilizer 2wt%, synthetic vegetable ester plasticizer 14wt%, ACR processing modifier 2wt%, PE wax 1wt%, UV-327 ultraviolet absorber 0.5wt% , titanium dioxide 4.5wt%, flame retardant and smoke suppressant 12.5wt%, AC blowing agent 1.5wt%.

[0044] The PVC foam mixing method and the steel-plastic composite method are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com