An organic photodetector based on a magnetic field effect spin-coating process and its preparation method

A photodetector and spin coating technology, which is applied in the materials of organic semiconductor devices, photovoltaic power generation, electric solid state devices, etc., can solve the problems of uneven thickness of the active layer film, poor performance of organic photodetectors, etc. Inhomogeneity, optimized donor and acceptor phase separation, improved effect of short circuit current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

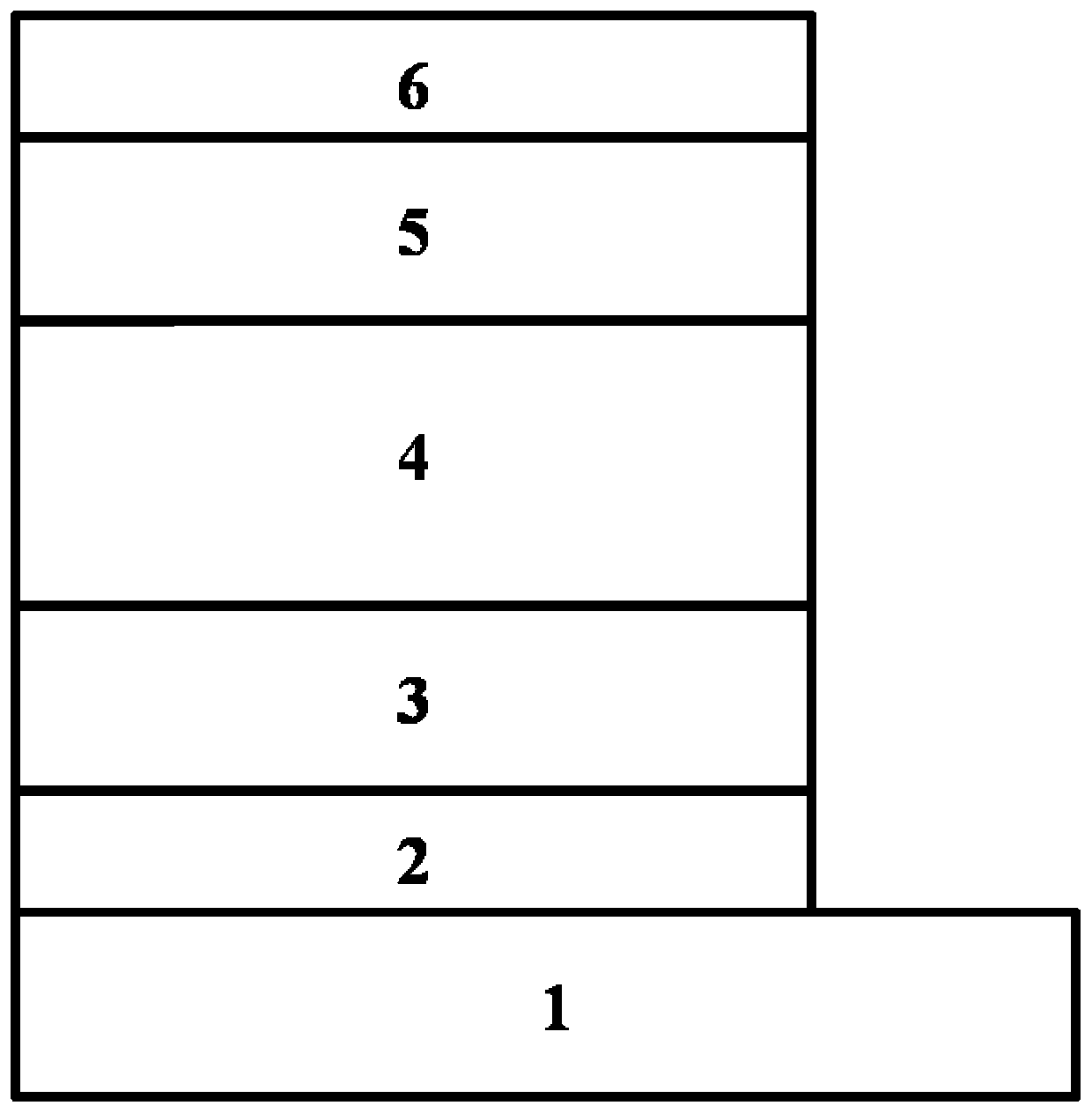

[0040] A method for preparing an organic photodetector as claimed in any one of claims 1-5, comprising the steps of:

[0041] Step 1: Clean the substrate, dry it with nitrogen, and place a magnet device under the substrate;

[0042] Step 2: Spin-coat the configured ZnO precursor solution onto the substrate, and perform thermal annealing on the spin-coated substrate to obtain an electron transport layer. The temperature of thermal annealing is 150°C for 15 minutes;

[0043] Step 3: On the electron transport layer, a photoactive layer is prepared by performing a magnetic field effect spin-coating process based on a magnet device, and the photoactive layer includes a homogeneously distributed film;

[0044] Step 4: In a vacuum of 3*10 3 Under the condition of Pa, evaporate MoO on the surface of the photoactive layer 3 obtaining a hole transport layer;

[0045] Step 5: Evaporating a metal anode on the hole transport layer to complete the preparation of the photodetector.

[0...

Embodiment 1

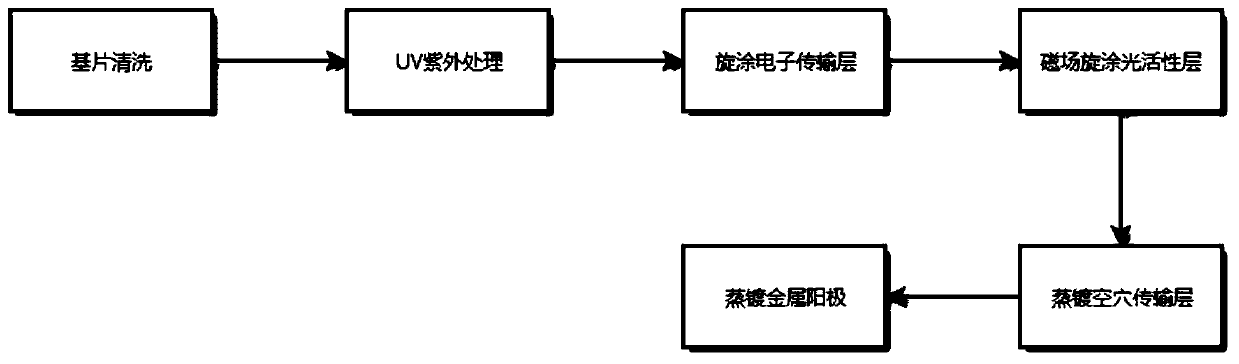

[0052] Such as figure 2 As shown, the substrate composed of a transparent substrate and a transparent conductive cathode with a surface roughness less than 1nm is cleaned, and then dried with nitrogen gas. The transparent conductive cathode material is ITO; UV ultraviolet treatment is performed on the surface of the transparent conductive cathode ITO Minutes later, spin-coat the ZnO precursor solution, the ZnO precursor solution includes 60% zinc acetate and 40% ethanolamine, the spin-coating speed is 800rpm, and the time is 12h, then carry out thermal annealing treatment (150 ℃, 15min) to prepare the electron transport layer, anneal P3HT:PC was prepared on the electron transport layer by magnetic field spin-coating method by heating on a constant temperature hot stage. 71 BM (1:1, 30mg / ml) photoactive layer (1100rpm, 30s), the corresponding thickness is 80nm, and the hole transport layer MoO is evaporated on the surface of the photoactive layer 3 (15nm); metal anode Ag (100...

Embodiment 2

[0054] Such as figure 2 As shown, the substrate composed of a transparent substrate and a transparent conductive cathode with a surface roughness of less than 1nm is cleaned, dried with nitrogen after cleaning, and subjected to UV ultraviolet treatment on the surface of the transparent conductive cathode ITO for 15 minutes and then spin-coated to prepare a ZnO precursor. Body solution, ZnO precursor solution includes 60% zinc acetate and 40% ethanolamine, the spin coating speed is 800rpm, the time is 12h, and then thermal annealing treatment (150 ℃, 15min) to prepare the electron transport layer, annealing adopts constant temperature hot stage heating, in On the electron transport layer, the P3HT: PC71BM: poly-BPIO (1:1:0.03, 30mg / ml) photoactive layer (1100rpm, 30s) was prepared by magnetic field spin coating, and the corresponding thickness was 80nm, and the anode was evaporated on the surface of the photoactive layer Buffer layer MoO3 (15nm); Metal anode Ag (100nm) is vapo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com