Fast recovery diode and manufacturing method thereof

A technology of rapid recovery and manufacturing method, applied in the field of diodes, can solve the problems of high switching loss and large forward voltage of diodes, and achieve the effects of reducing switching loss, reducing forward voltage and improving practicality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

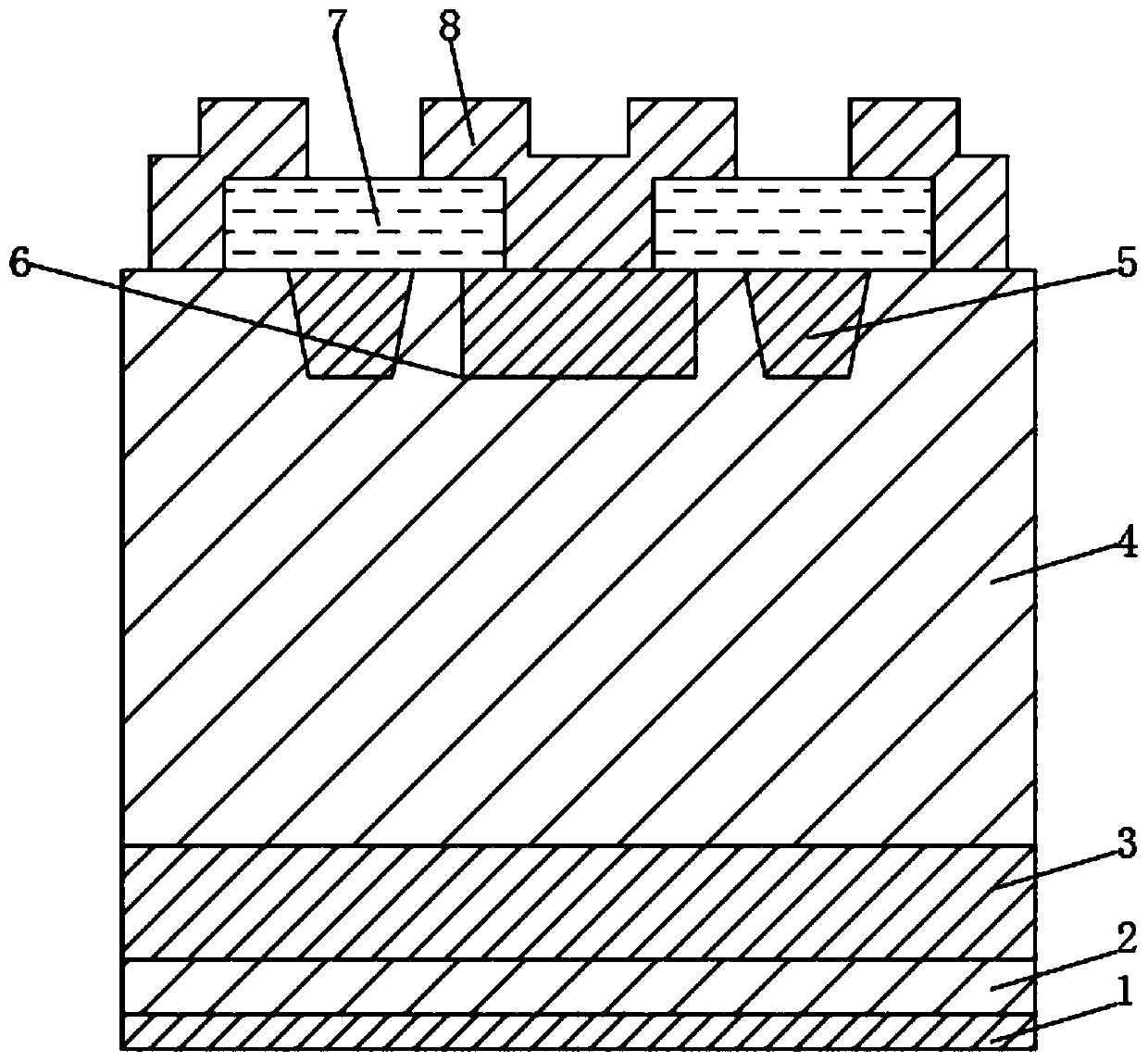

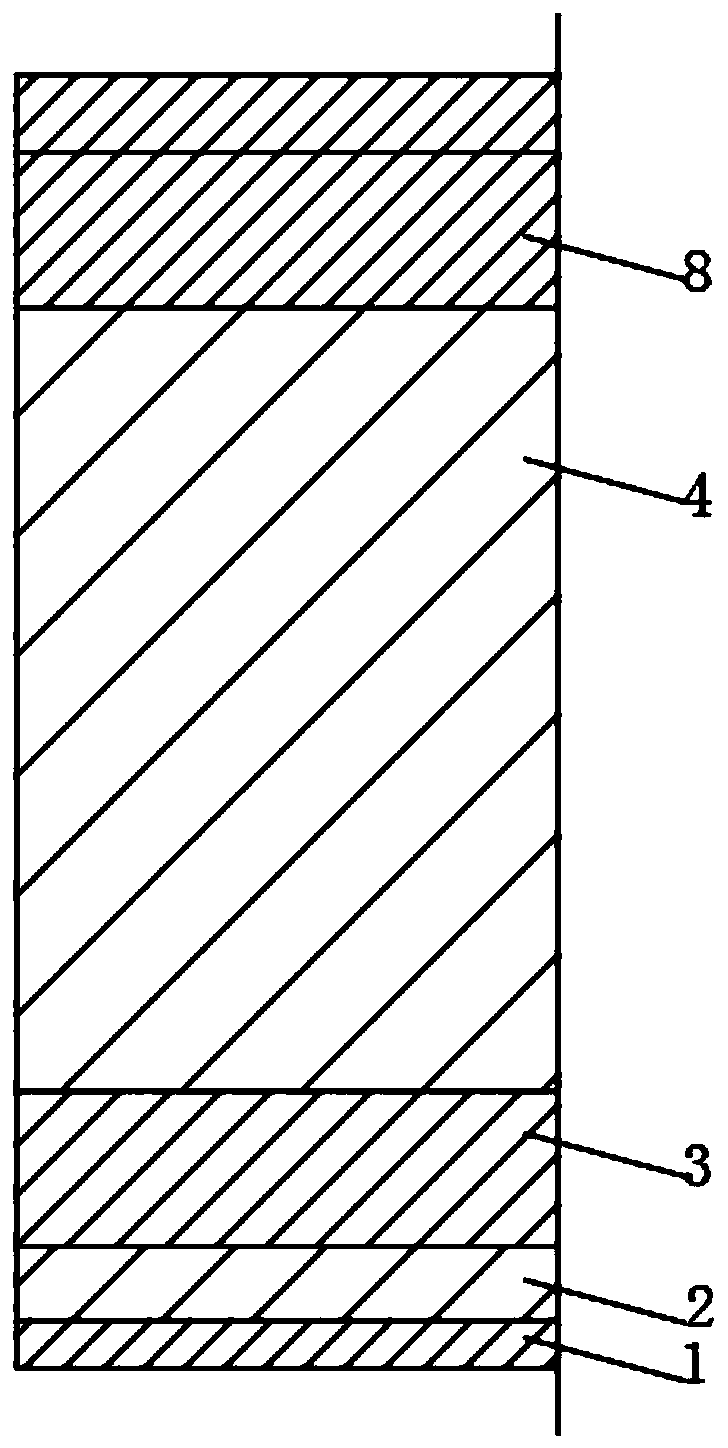

[0024] see figure 1 and figure 2 , the present invention provides a technical solution: a fast recovery diode, comprising a collector 1, an N-type buffer 2 is arranged on the collector 1, an N-type substrate 3 is arranged on the N buffer 2, and an N-type substrate 3 The N-field stop layer 4 is arranged on the N-field stop layer 4, and the P base region 5 and the P+ ohmic contact region 6 are arranged on the N-field stop layer 4. On the N-field stop layer 4, on the P base region 5 and on the P+ ohmic contact region 6 Both are provided with borophosphosilicate glass 7 and metal layer 8, and the metal layer 8 and borophosphoric acid glass 7 are arranged in close contact.

[0025] Fast recovery diodes are fabricated as follows: chip preparation, boron diffusion, oxidation, growth of Si 3 N 4 , photolithography, engraved passivation Si 3 N 4 or SiO 2 , Mesa corrosion, oxidation, etch and etch passivation of silicon groove 3 N 4 or SiO 2 , oxidize, corrode SiO 2 , oxidati...

Embodiment 2

[0038] see figure 1 and figure 2 , the present invention provides a technical solution: a fast recovery diode, comprising a collector 1, an N-type buffer 2 is arranged on the collector 1, an N-type substrate 3 is arranged on the N buffer 2, and an N-type substrate 3 The N-field stop layer 4 is arranged on the N-field stop layer 4, and the P base region 5 and the P+ ohmic contact region 6 are arranged on the N-field stop layer 4. On the N-field stop layer 4, on the P base region 5 and on the P+ ohmic contact region 6 Both are provided with borophosphosilicate glass 7 and metal layer 8, and the metal layer 8 and borophosphoric acid glass 7 are arranged in close contact.

[0039] Fast recovery diodes are fabricated as follows: chip preparation, boron diffusion, oxidation, growth of Si 3 N 4 , photolithography, engraved passivation Si 3 N 4 or SiO 2 , Mesa corrosion, oxidation, etch and etch passivation of silicon groove 3 N 4 or SiO 2 , oxidize, corrode SiO 2 , oxidati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com