Modification method of silicon negative electrode material for lithium ion battery

A lithium-ion battery, silicon anode technology, applied in battery electrodes, negative electrodes, secondary batteries, etc., can solve the problems of silicon material pulverization, affecting cycle performance, etc., to improve conductivity, simple and effective preparation methods, and reduce volume. inflated effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] A modification method of silicon negative electrode material for lithium ion battery, according to the following steps:

[0017] Using 1g of nano-silica powder and 10g of tetrabutyl titanate as raw materials, react under hydrothermal conditions at 150°C for 12 hours, filter and dry to obtain a precursor; After mixing evenly, the carbon / nitrogen source used is one of guanidine hydrochloride and urea. Under a nitrogen atmosphere, the temperature was raised to 900°C at a heating rate of 5°C / min, kept for 2 hours, and then naturally cooled to room temperature to obtain a multilayer structure. silicon-based anode material.

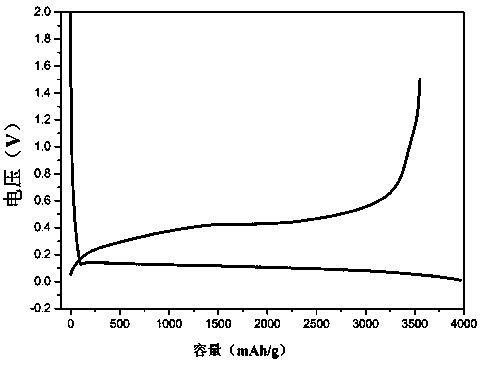

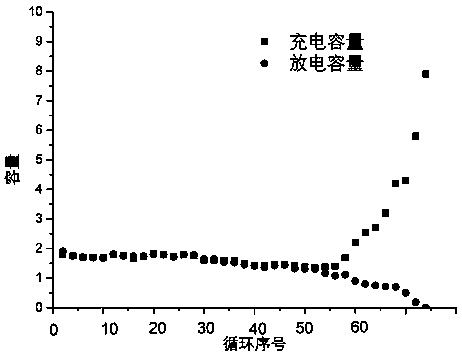

[0018] The first charge and discharge efficiency graph of the preparation of silicon-based negative electrode materials is shown in figure 1 , and the cycle performance graph see figure 2 , the cycle performance is significantly improved.

Embodiment 2

[0020] A modification method of silicon negative electrode material for lithium ion battery, similar to embodiment 1, according to the following steps:

[0021] Take 1g of nano-silica powder and 10g of tetrabutyl titanate as raw materials, react at 180°C for 12 hours under hydrothermal conditions, filter and dry to obtain a precursor; then mix the precursor and carbon / nitrogen source at a mass ratio of 1:8 The ratio was mixed evenly, and the temperature was raised to 900°C at a heating rate of 8°C / min under a nitrogen atmosphere, kept for 2 hours, and then naturally cooled to room temperature.

Embodiment 3

[0023] A modification method of silicon negative electrode material for lithium ion battery, similar to embodiment 1, according to the following steps:

[0024] Take 1g of nano-silica powder and 10g of tetrabutyl titanate as raw materials, react under hydrothermal conditions of 200°C for 12h, filter and dry to obtain the precursor. Then the precursor and carbon / nitrogen source were mixed evenly at a mass ratio of 1:10, and the temperature was raised to 900 °C at a heating rate of 10 °C / min in a nitrogen atmosphere, kept for 2 h, and then naturally cooled to room temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com