Battery negative electrode, preparation method thereof and secondary battery

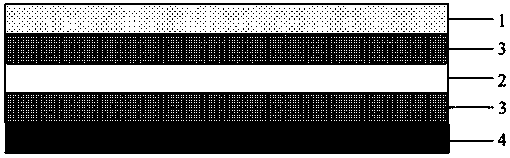

A battery negative electrode and conductive layer technology, applied to battery electrodes, electrode carriers/current collectors, circuits, etc., can solve problems such as battery cycle instability, achieve the effects of inhibiting volume expansion, preventing erosion and reaction, and enhancing electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The above-mentioned negative electrode of the battery is prepared by the following preparation method of the negative electrode of the battery.

[0034] Correspondingly, the embodiment of the present invention also provides a method for preparing a negative electrode of a battery. The method comprises the steps of:

[0035] S01. placing the metal substrate in the cationic polymer solution for soaking reaction, so that the cationic polymer in the cationic polymer solution is combined on the surface of the metal substrate to form a cationic polymer layer to prepare a crude product;

[0036] S02. Place the crude product in the conductive solution for soaking reaction, make the conductive material in the conductive solution bond to the surface of the cationic polymer layer to form a conductive layer, and prepare the negative electrode of the battery.

[0037] Specifically, in the above step S01, the cationic polymer of the cationic polymer solution is selected from at leas...

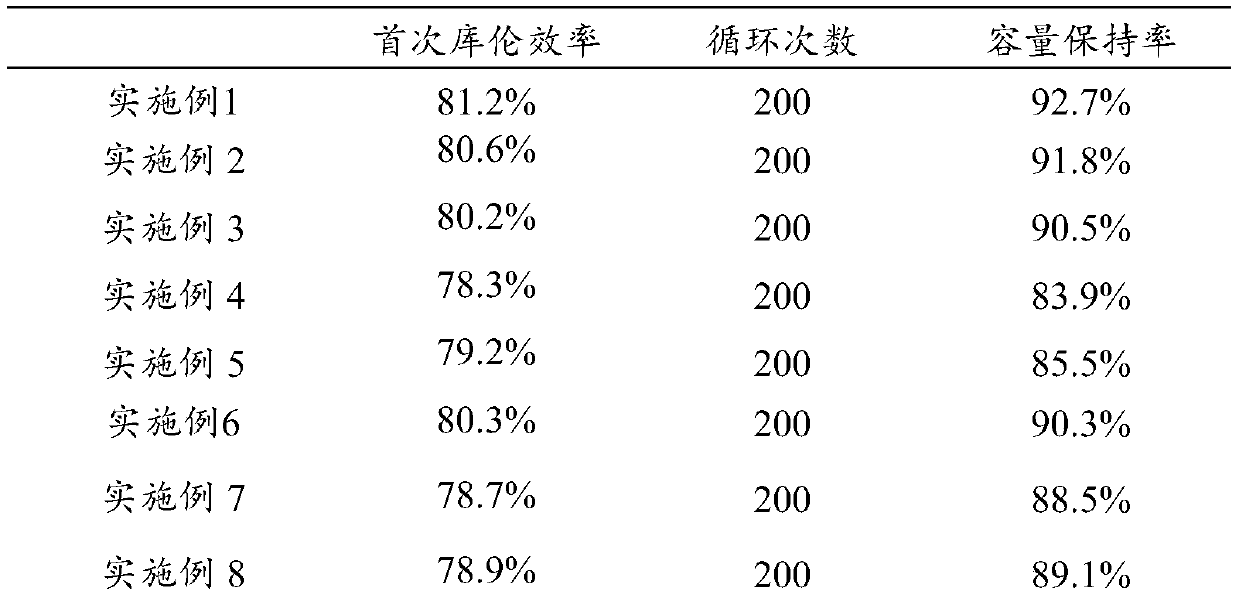

Embodiment 1

[0057] Preparation of battery negative electrode

[0058] Select aluminum foil as the metal substrate, cut the aluminum foil to obtain a disc with a diameter of 12mm; place the cut substrate in absolute ethanol for ten minutes of ultrasonic cleaning, repeat the above steps three times to ensure that the substrate is clean; use nitrogen as the inert In a gas atmosphere, the surface-cleaned substrate is dried in the nitrogen atmosphere.

[0059] Configure the cationic polymer solution: select polydiallyldimethylammonium chloride as the cationic polymer, configure a cationic polymer solution with a volume percentage concentration of 1%, and its preparation method is as follows: measure 1mL PDDA and dissolve it in 100mL water, Stir to make it mix uniformly to obtain a cationic polymer solution with a concentration of 1% by volume;

[0060] Configure conductive solution: choose graphite oxide as the conductive material, and configure a conductive solution with a concentration of 1...

Embodiment 2

[0066] Compared with Example 1, "choose graphite oxide as the conductive material" was replaced with "choose oxidized carbon nanotubes as the conductive material"; other steps were the same as in Example 1 to prepare the negative electrode of the battery and the secondary battery.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com