Preparation method of PVDF/ZrO2-PVA modified ultrafiltration membrane

An ultrafiltration membrane and modification technology, which is applied in the field of membrane materials, can solve the problems of deterioration of membrane separation characteristics, influence on separation effect, decrease of membrane flux, etc., achieve excellent hydrophilicity and anti-pollution performance, improve treatment efficiency, reduce Effect of Surface Roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

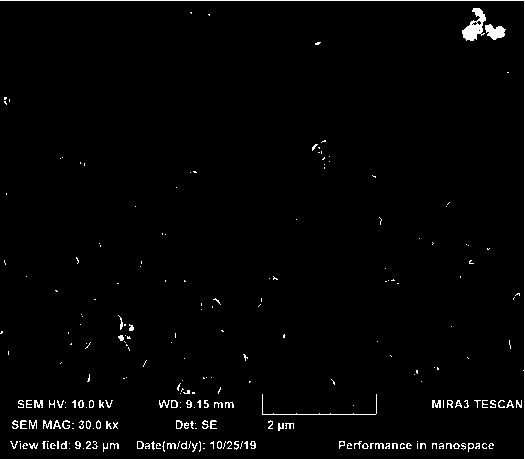

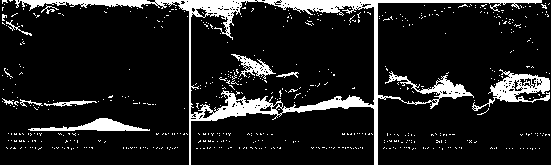

Image

Examples

Embodiment 1

[0027] A PVDF / ZrO 2 -The preparation method of PVA modified ultrafiltration membrane, comprises the following steps:

[0028] (1) Take 15g of PVDF, 28g of PVA and 1g of ZrO 2 Dissolve 73g of dimethylacetamide (DMAc) solution, then add 5g porogen polyvinylpyrrolidone PVP+LiCl, and then bathe in water;

[0029] (2) Put the casting solution in a water bath at a temperature of 58-62°C and stir, first stir at a speed of 600r / min for 1h, then stir at a speed of 90r / min for 5h, then let it stand at room temperature for 30min, and put it in a vacuum drying oven for 60 Dry at ℃ for 6h;

[0030] (3) After scraping off the ultrafiltration membrane with a film thickness of 200um at room temperature, immediately immerse it in a 20% ethanol aqueous coagulation bath.

Embodiment 2

[0032] A PVDF / ZrO 2 -The preparation method of PVA modified ultrafiltration membrane, comprises the following several steps:

[0033] (1) Take 15g of PVDF, 24g of PVA and 1g of ZrO 2 Dissolve 73g of dimethylacetamide (DMAc) solution, then add 5g porogen polyvinylpyrrolidone PVP+LiCl, and then bathe in water;

[0034] (2) Put the casting solution in a water bath at a temperature of 58-62°C and stir, first stir at a speed of 600r / min for 1h, then stir at a speed of 90r / min for 5h, then let it stand at room temperature for 30min, and put it in a vacuum drying oven for 60 Dry at ℃ for 6h;

[0035] (3) After scraping off the ultrafiltration membrane with a film thickness of 200um at room temperature, immediately immerse it in a 20% ethanol aqueous coagulation bath.

Embodiment 3

[0037] A PVDF / ZrO 2 -The preparation method of PVA modified ultrafiltration membrane, comprises the following several steps:

[0038] (1) Take 15g of PVDF, 24g of PVA and 1g of ZrO 2 Dissolve 73g of dimethylacetamide (DMAc) solution, then add 5g porogen polyvinylpyrrolidone PVP+LiCl, and then bathe in water;

[0039] (2) Put the casting solution in a water bath at a temperature of 58-62°C and stir, first stir at a speed of 600r / min for 1h, then stir at a speed of 90r / min for 5h, then let it stand at room temperature for 30min, and put it in a vacuum drying oven for 60 Dry at ℃ for 6h;

[0040] (3) After scraping off the ultrafiltration membrane with a film thickness of 200um at room temperature, immediately immerse it in a 20% ethanol aqueous coagulation bath.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com