Green production method and device of levetiracetam key intermediate S-2-methyl aminobutyrate

The technology of methyl aminobutyrate and S-2- is applied in the field of levetiracetam key intermediate S-2-aminobutyric acid methyl ester, which can solve problems such as environmental pollution and achieve the effect of environmental protection of the process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

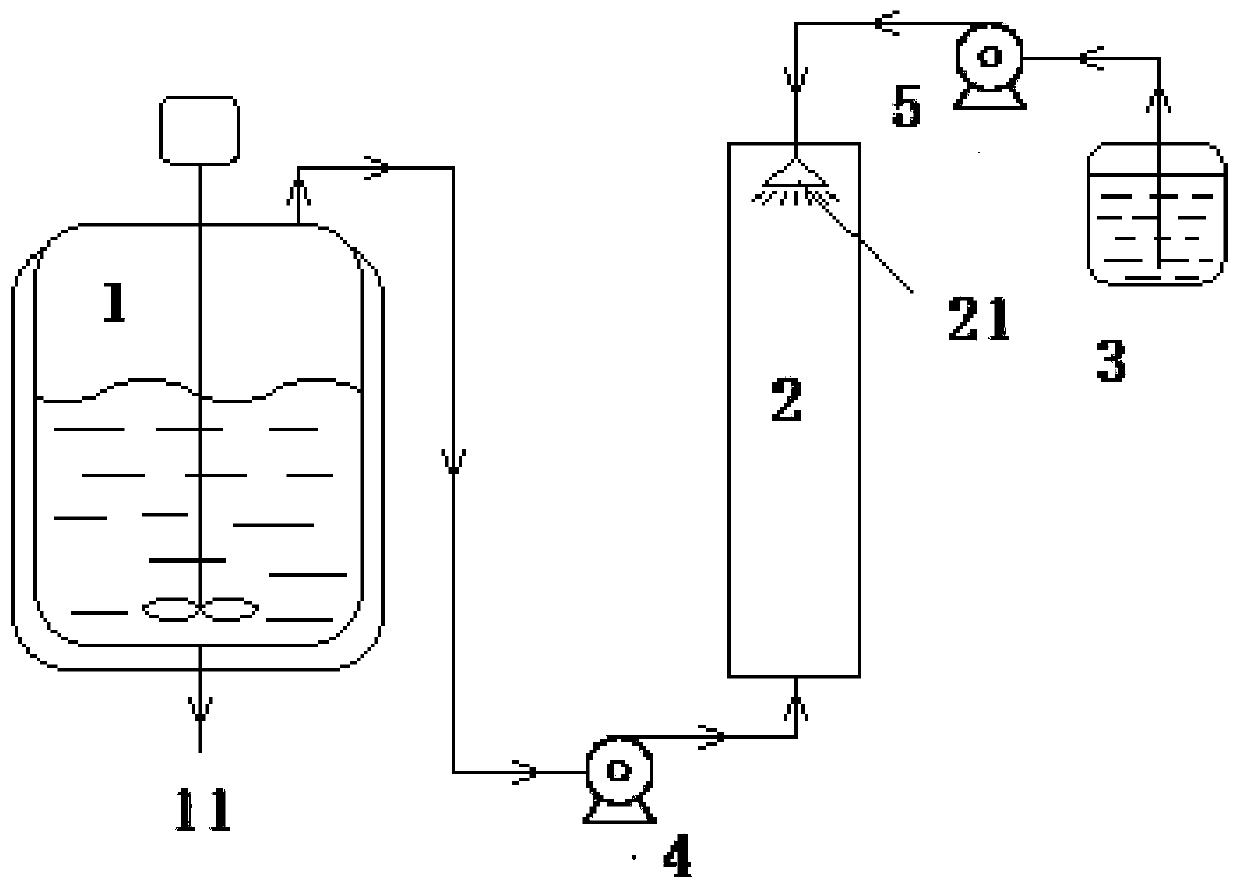

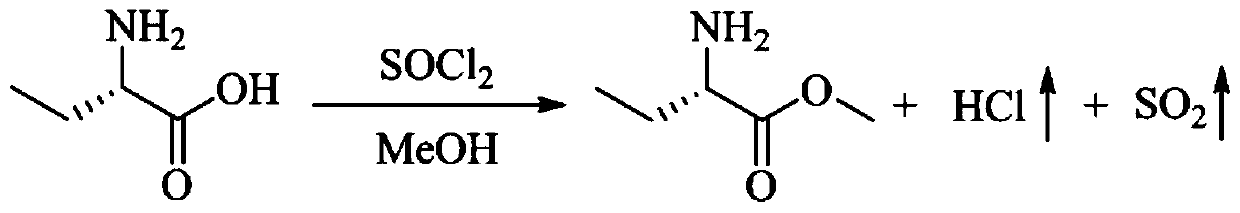

[0033] Embodiment 1: A kind of green production method of levetiracetam key intermediate S-2-aminobutyric acid methyl ester comprises the following steps:

[0034] S1. Will S -2-aminobutyric acid and methanol in a molar ratio of 1:1, S -2-Aminobutyric acid and thionyl chloride are pumped into reactor 1 at a molar ratio of 1:5, heated to a reaction temperature of 50°C, and stirred vigorously for 5 hours, and the hydrogen chloride and sulfur dioxide produced by the reaction are extracted from the top of reactor 1;

[0035] S2. Pump the hydrogen chloride and sulfur dioxide extracted from the top of the reaction kettle 1 into the bottom of the gas absorption tower 2, pump the alkaline aqueous solution into the top of the gas absorption tower 2, and pump the potassium hydroxide aqueous solution into the top of the tower at a flow rate of 0.1mol / h to absorb hydrogen chloride and sulfur dioxide gas;

[0036] S3. The reaction solution is discharged from the bottom of the reaction ke...

Embodiment 2

[0039] Embodiment 2: A kind of green production method of levetiracetam key intermediate S-2-aminobutyric acid methyl ester comprises the following steps:

[0040] S1. Will S -2-aminobutyric acid and methanol in a molar ratio of 1:3, S -2-Aminobutyric acid and thionyl chloride are pumped into the reaction kettle 1 according to the molar ratio of 1:1, heated to a reaction temperature of 60°C, vigorously stirred for 7 hours, and the hydrogen chloride and sulfur dioxide produced by the reaction are extracted from the top of the reaction kettle 1;

[0041] S2. pump the hydrogen chloride and sulfur dioxide extracted from the top of the reactor 1 into the gas absorption tower 2 bottom, the gas absorption tower 2 top is pumped into the alkaline aqueous solution, and the tower top is pumped into the sodium carbonate aqueous solution with a flow rate of 0.3mol / h to absorb hydrogen chloride and sulfur dioxide gas;

[0042] S3. The reaction solution is discharged from the bottom of the r...

Embodiment 3

[0044] Embodiment 3: a kind of green production method of levetiracetam key intermediate S-2-aminobutyric acid methyl ester comprises the following steps:

[0045] S1. Will S -2-aminobutyric acid and methanol in a molar ratio of 1:5, S -Pump 2-aminobutyric acid and thionyl chloride into reactor 1 at a molar ratio of 1:2, heat to a reaction temperature of 30°C, and vigorously stir for 10 hours, and the hydrogen chloride and sulfur dioxide produced by the reaction are extracted from the top of reactor 1;

[0046] S2. The hydrogen chloride and sulfur dioxide extracted from the top of the reactor 1 are pumped into the bottom of the gas absorption tower 2, and the top of the gas absorption tower 2 is pumped into an alkaline aqueous solution, and the top of the tower is pumped into an aqueous sodium bicarbonate solution at a flow rate of 0.5mol / h to absorb hydrogen chloride and sulfur dioxide gas;

[0047] S3. The reaction solution is discharged from the bottom of the reaction ket...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com