Water-based PES coating and preparation method thereof

A water-based and coating technology, applied in the direction of coating, etc., can solve the problems of non-stickiness, poor high temperature resistance and wear resistance, not environmental protection, high price, etc., and achieve the effect of good adhesion, low VOC content and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

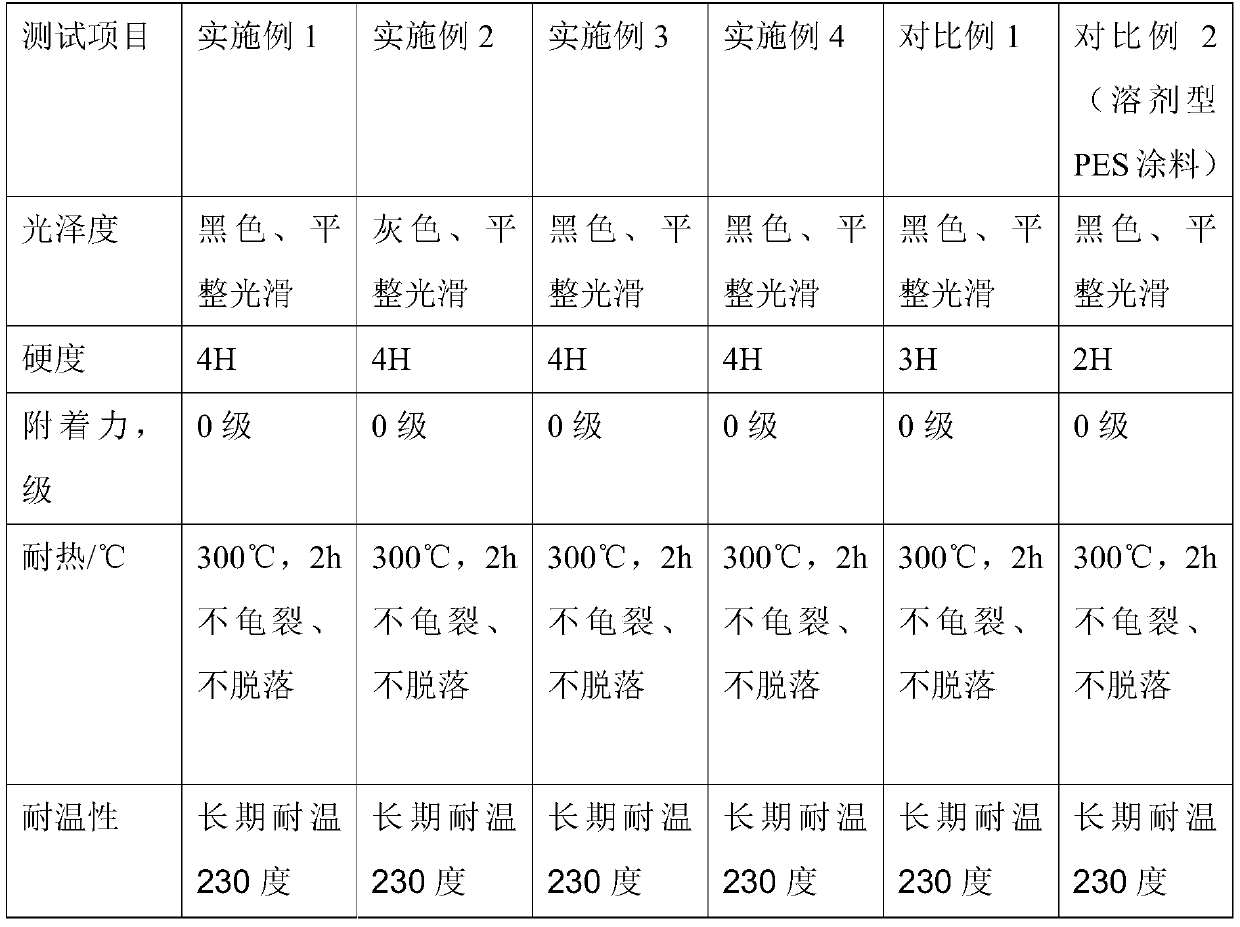

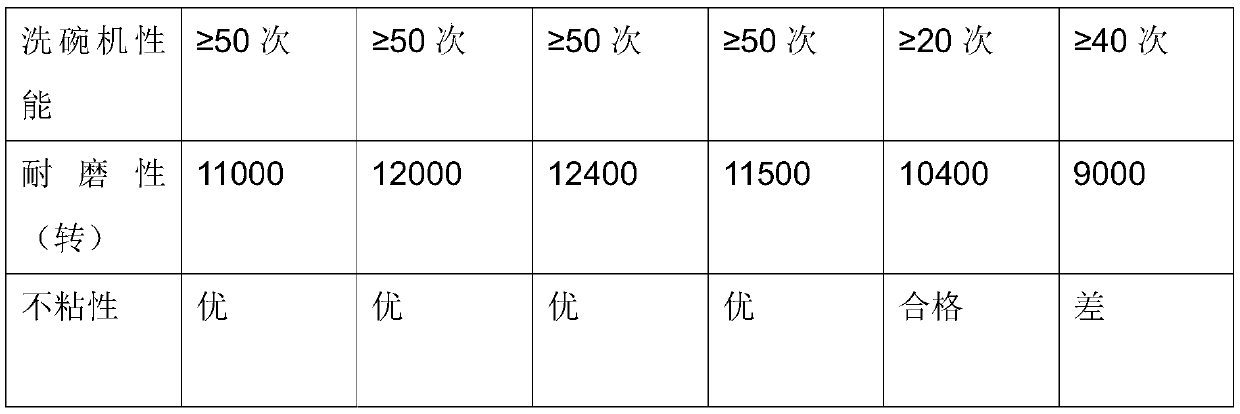

Examples

Embodiment 1

[0024] A water-based PES paint, prepared from the following raw materials in parts by weight: 20 parts of water-based PES resin emulsion, 0.2 parts of ethylene glycol, 0.2 parts of iron red, 0.15 parts of titanium chrome brown, 0.5 parts of barium sulfate, and 0.5 parts of talcum powder , 0.5 parts of polytetrafluoroethylene resin, 0.5 parts of polytetrafluoroethylene-perfluoroalkoxy resin, 1.05 parts of alkylphenol polyoxyethylene ether and 5.4 parts of water.

[0025] A preparation method for water-based PES paint, comprising the following steps:

[0026] (1) Disperse the water-based PES resin emulsion, ethylene glycol, iron red, titanium chrome brown, barium sulfate, talcum powder and part of water evenly, and then pass through the grinder to grind;

[0027] (2) Add polytetrafluoroethylene resin, polytetrafluoroethylene-perfluoroalkoxy resin and alkylphenol polyoxyethylene ether and stir, and then add the remaining water to adjust the viscosity of the paint to obtain a wate...

Embodiment 2

[0029] A water-based PES paint, prepared from the following raw materials in parts by weight: 70 parts of water-based PES resin emulsion, 4.8 parts of ethylene glycol, 5 parts of iron red, 4 parts of titanium chrome brown, 15 parts of barium sulfate, and 10 parts of talcum powder , 8 parts of polytetrafluoroethylene resin, 7 parts of polytetrafluoroethylene-perfluoroalkoxy resin, 3.2 parts of alkylphenol polyoxyethylene ether and 35 parts of water.

[0030] A preparation method for water-based PES paint, comprising the following steps:

[0031] (1) Disperse the water-based PES resin emulsion, ethylene glycol, iron red, titanium chrome brown, barium sulfate, talcum powder and part of water evenly, and then pass through the grinder to grind;

[0032] (2) Add polytetrafluoroethylene resin, polytetrafluoroethylene-perfluoroalkoxy resin and alkylphenol polyoxyethylene ether and stir, and then add the remaining water to adjust the viscosity of the paint to obtain a water-based PES p...

Embodiment 3

[0034] A water-based PES paint, prepared from the following raw materials in parts by weight: 40 parts of water-based PES resin emulsion, 2 parts of ethylene glycol, 2 parts of iron red, 1.5 parts of titanium chrome brown, 5 parts of barium sulfate, and 5 parts of talcum powder , 3 parts of polytetrafluoroethylene resin, 2 parts of polytetrafluoroethylene-perfluoroalkoxy resin, 2.5 parts of alkylphenol polyoxyethylene ether and 19 parts of water.

[0035] A preparation method for water-based PES paint, comprising the following steps:

[0036] (1) Disperse the water-based PES resin emulsion, ethylene glycol, iron red, titanium chrome brown, barium sulfate, talcum powder and part of water evenly, and then pass through the grinder to grind;

[0037] (2) Add polytetrafluoroethylene resin, polytetrafluoroethylene-perfluoroalkoxy resin and alkylphenol polyoxyethylene ether and stir, and then add the remaining water to adjust the viscosity of the paint to obtain a water-based PES pai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com