Integrated water cooling cold water module unit

A technology for cold water modules and units, applied in refrigerators, refrigeration components, water shower coolers, etc., can solve the problems of increased construction cost, low heat exchange efficiency, large cooling water consumption, etc. The effect of sufficient heat exchange and reduction of construction difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

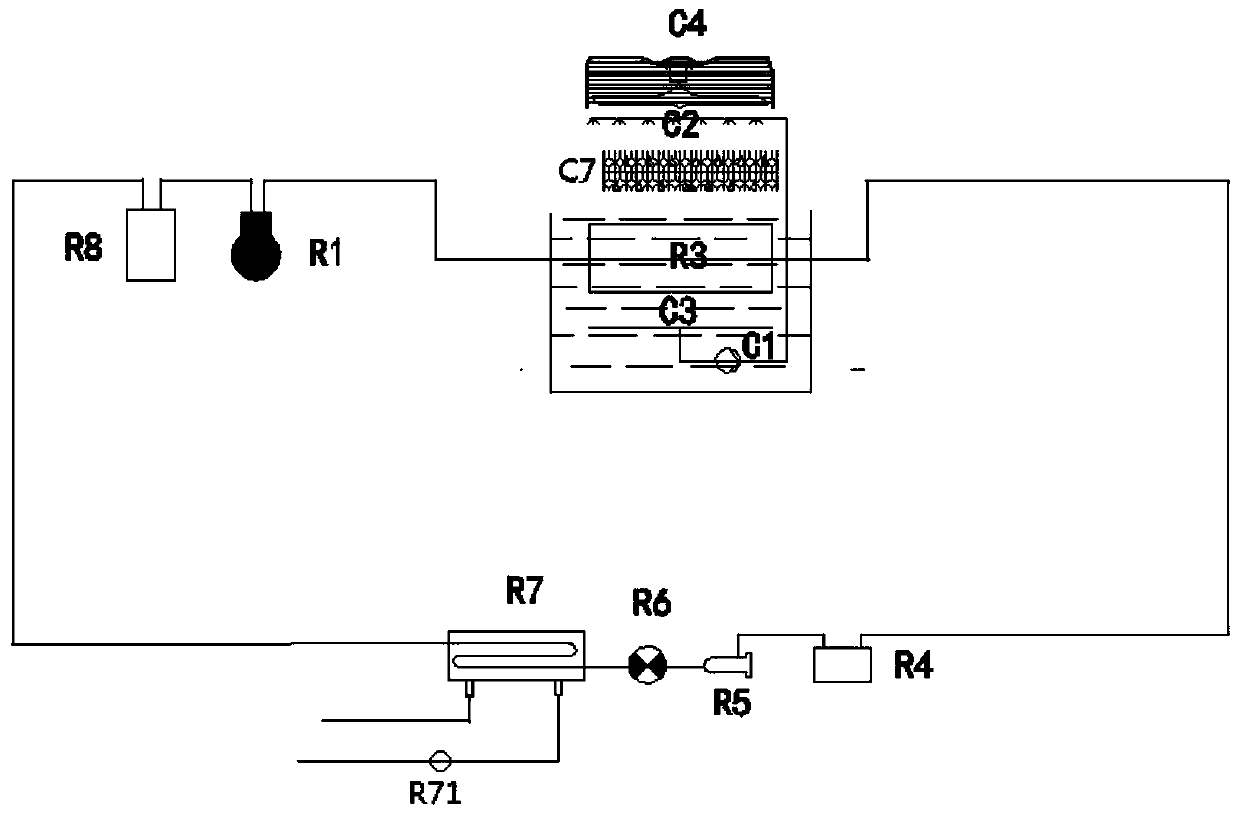

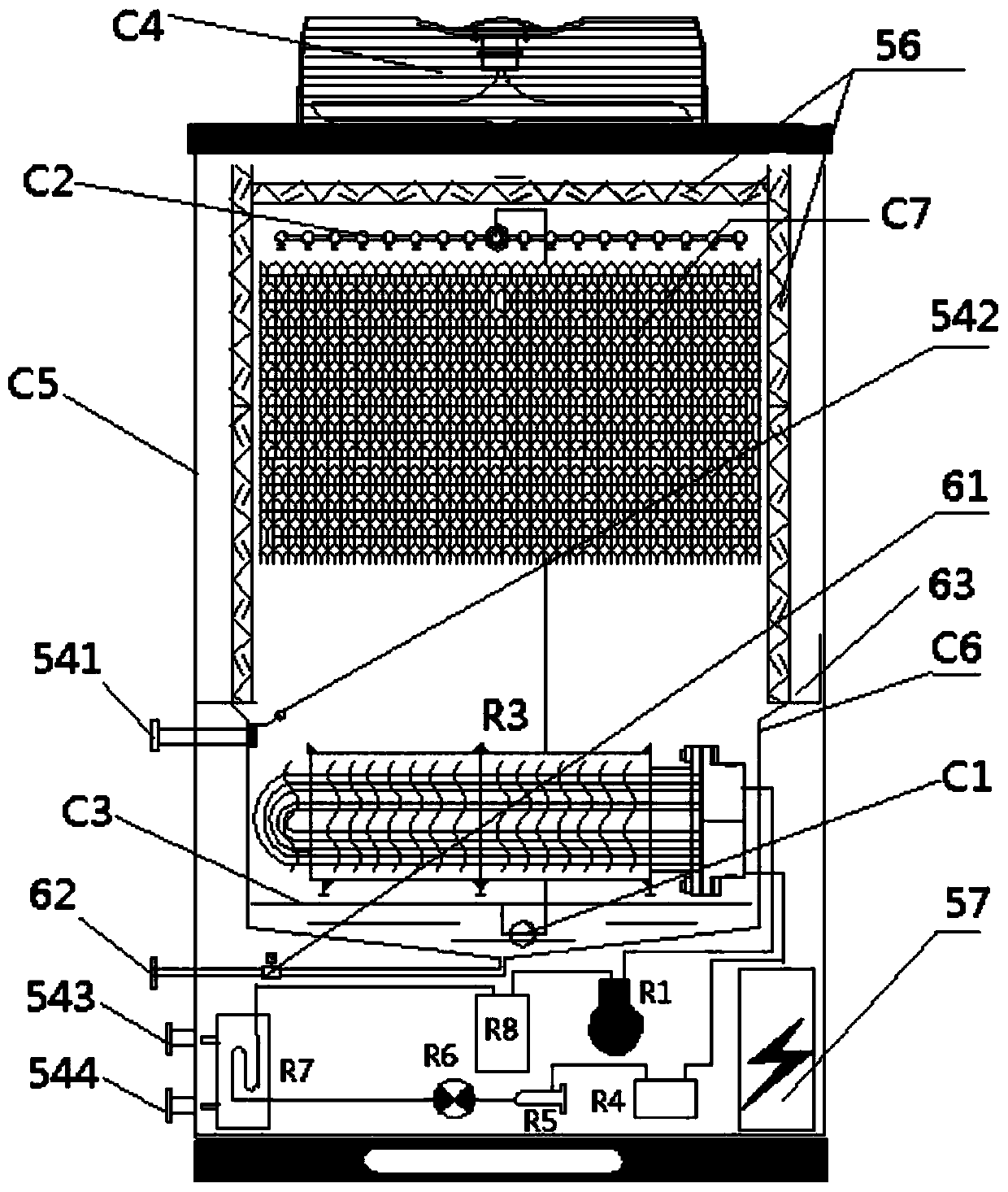

Method used

Image

Examples

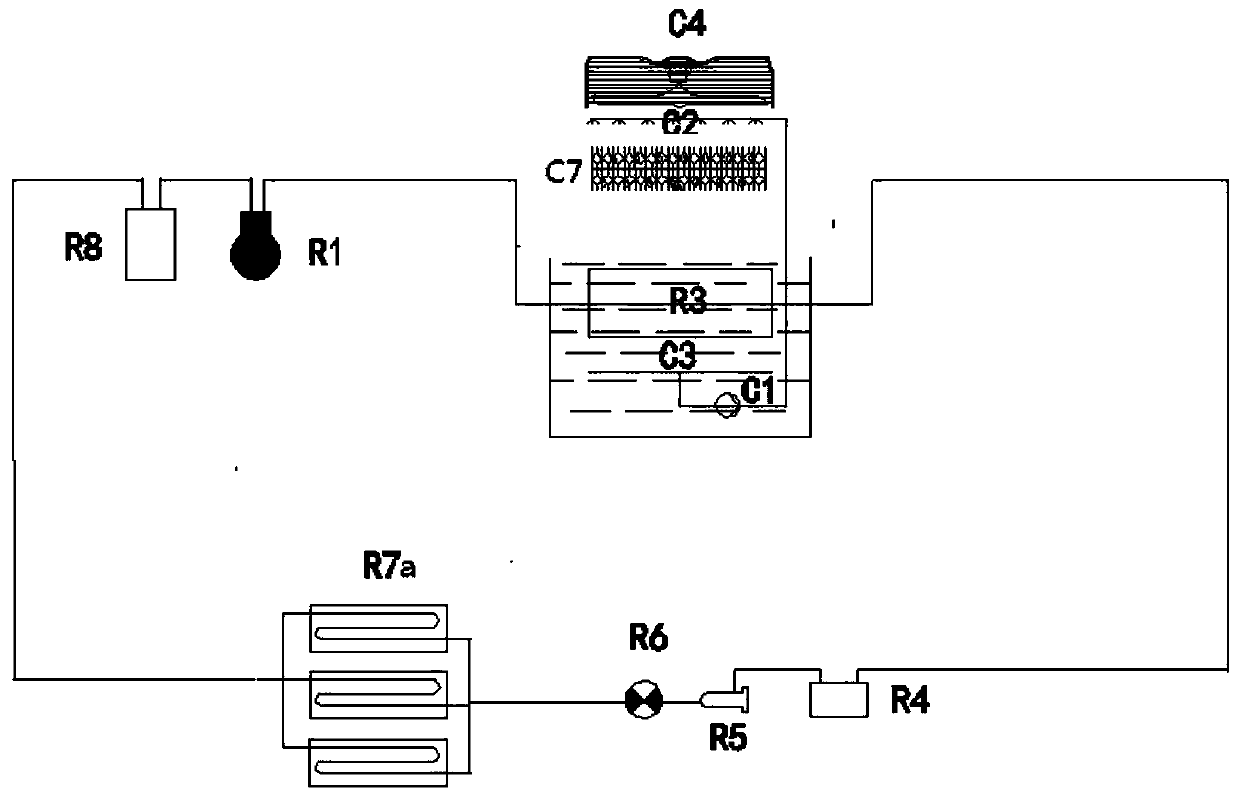

Embodiment 2

[0055] Embodiment two, such as figure 2 As shown, the indoor side heat exchanger 7R is replaced by an indoor multi-unit unit 7Ra. At this time, the integrated mixed-cooled chilled water module unit is a water-cooled multi-unit unit (direct expansion unit), and the multi-unit indoor unit 7Ra includes Refrigerant fin heat exchanger and indoor side fan, the indoor side fan makes air flow through the surface of the refrigerant fin heat exchanger, directly vaporizes the refrigerant to absorb the heat of the indoor air to cool down, and is used for cooling of the water-cooled multi-unit unit. At this time, the low-temperature and low-pressure liquid refrigerant enters each refrigerant fin heat exchanger, and under the action of each indoor side fan, it exchanges heat with the indoor air flowing through the surface of each refrigerant fin heat exchanger at the same time. The liquid refrigerant absorbs the heat of the air and vaporizes. It is refrigerant steam, the indoor air is cool...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com