Red mud soil substrate and preparation method thereof

A technology for red mud and soil, applied in the field of red mud soil matrix and its preparation, can solve the problems of yard maintenance requiring a certain cost, poor red mud soil characteristics, low organic nutrient content, etc., and achieve harmlessness and reduction. The effect of improving the growth environment of microorganisms and increasing organic nutrients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

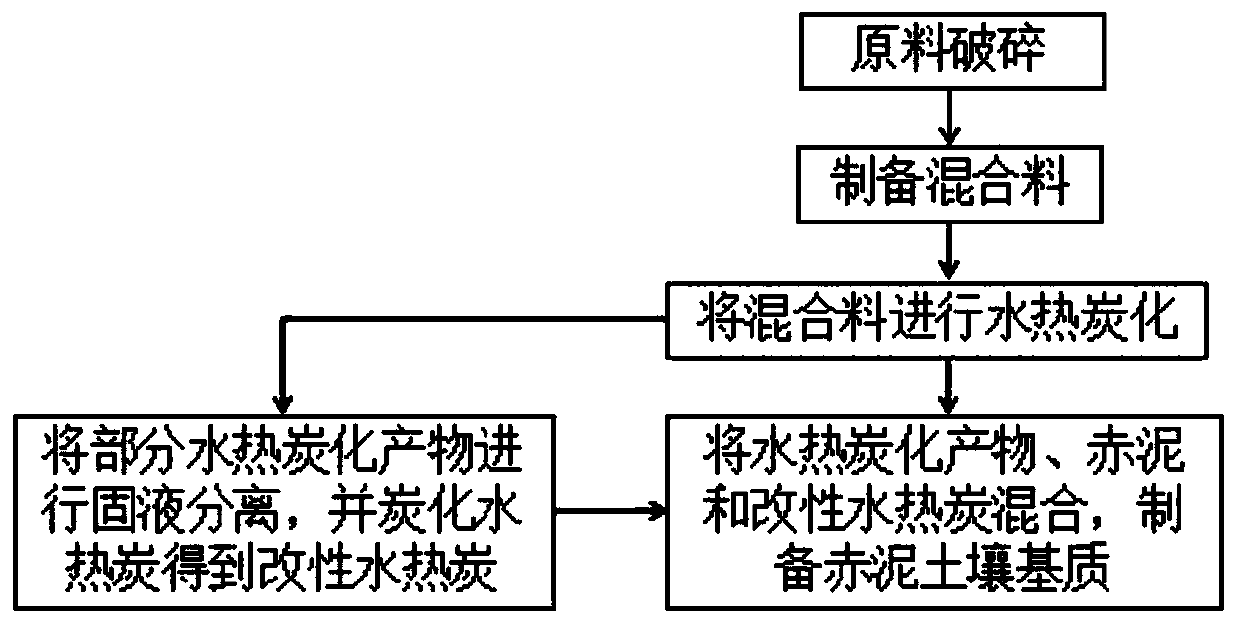

[0045] The application provides a preparation method of red mud soil matrix, such as figure 1 shown, including the following steps:

[0046] Step S1, using a crusher to crush the biomass raw material into biomass powder;

[0047] Step S2, transporting biomass powder, water and catalyst into a stirring tank for stirring to obtain a mixture;

[0048] Step S3, adding the mixture to the autoclave at a speed of V 1 The autoclave is heated up to T 1 After that, keep it warm for 5-20 hours; then cool to room temperature to obtain the hydrothermal carbonization product;

[0049] Step S4, performing solid-liquid separation on part of the hydrothermal carbonization products to obtain hydrothermal charcoal and hydrothermal charcoal liquid; the remaining hydrothermal carbonization products are set aside;

[0050] Step S5, carbonizing the hydrothermal charcoal to obtain modified hydrothermal charcoal;

[0051] Step S6, mix the modified hydrothermal charcoal, the remaining hydrothermal...

Embodiment 1

[0098] The preparation method of the red mud soil matrix of the present embodiment may further comprise the steps:

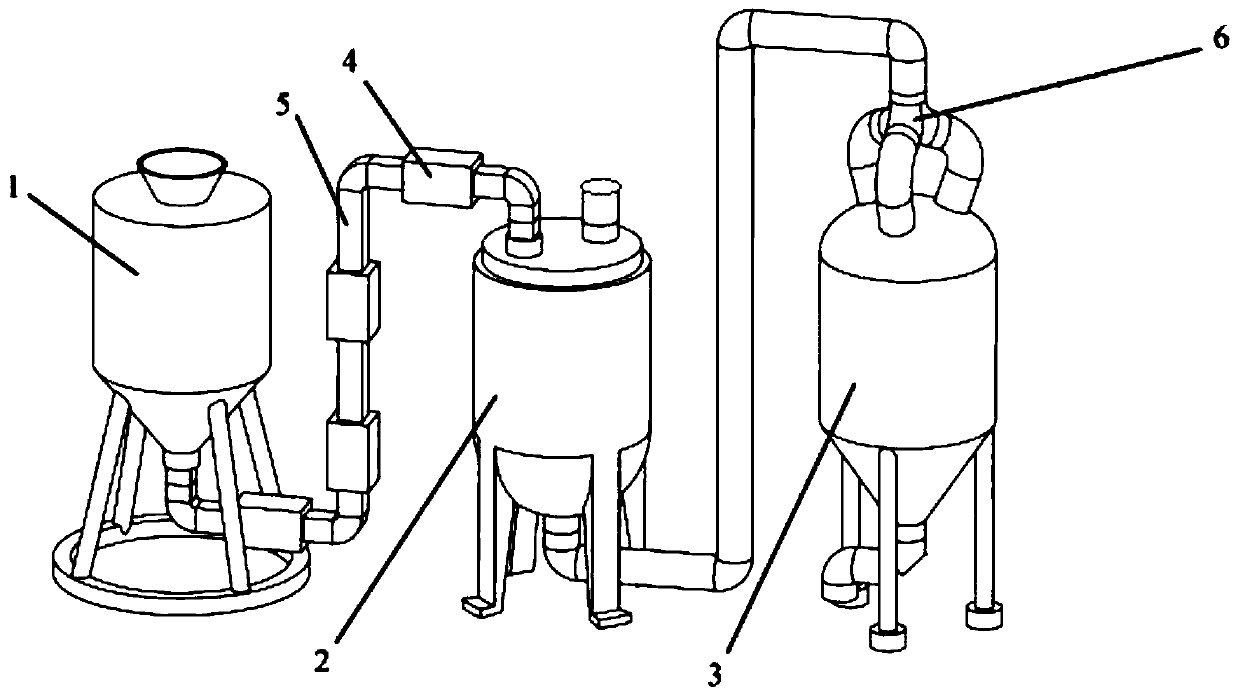

[0099] Step S1, adding the biomass raw material (in this embodiment, straw) into the crusher 1, and the crusher 1 crushes the straw into a powder with a particle size of 1 mm;

[0100] Step S2, use the material lifting mechanism 4 to transport the powder into the mixing tank 2 from the first feeding port, and then add water and catalyst (the catalyst is red mud in this embodiment) into the mixing tank 2 through the second feeding port , stirring to obtain a mixture, the stirring speed is 500rpm, the stirring time is 10min, and the mass ratio of powder, water and catalyst is: 0.05:1:0.0025;

[0101] Step S3, adding the mixture to the autoclave 3, heating the autoclave 3 at 200°C / h, and keeping the temperature at 200°C for 20 hours; then cooling to room temperature to obtain a hydrothermal carbonization product; wherein, the mixture Volume is 1 / 3 of the volume of...

Embodiment 2

[0107] The preparation method of the red mud soil matrix of the present embodiment may further comprise the steps:

[0108] Step S1, adding the biomass raw material (fallen leaves in this embodiment) into the crusher 1, and the crusher 1 crushes the fallen leaves into a powder with a particle size of 3 mm;

[0109] Step S2, use the material lifting mechanism 4 to transport the powder into the stirring tank 2 from the first feeding port, and then add water and catalyst (the catalyst is potassium carbonate in this embodiment) into the stirring tank 2 through the second feeding port , stirring to obtain a mixture, the stirring speed is 200rpm, the stirring time is 30min, and the mass ratio of powder, water and catalyst is: 0.2:1:0.01;

[0110] Step S3, adding the mixture to the autoclave 3, heating the autoclave 3 at 150°C / h, and keeping the temperature at 380°C for 10 hours; then cooling to room temperature to obtain a hydrothermal carbonization product; wherein, the mixture Vo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com