Low-GI steamed cake rich in dietary fibers and preparation method thereof

A technology of dietary fiber and steamed cakes, which is applied in the functions of food ingredients, ingredients of oil-containing food, food science, etc., can solve the problems that the taste needs to be improved, it is not suitable for people who lose weight or people with diabetes, and the content of carbohydrates and fats is high. To achieve the effect of good taste, good intestinal health, fluffy and soft tissue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] In addition, the present invention also proposes a method for preparing the above-mentioned cake, which includes the following steps: steaming the mixed raw materials.

[0038] In some embodiments, when the raw material includes vegetable oil, raw materials other than vegetable oil can be mixed first to prepare batter, and then the batter is mixed with vegetable oil and steamed.

[0039] For reference, the batter preparation method may include: mixing trehalose, maltitol and egg liquid, and beating to obtain the first system; mixing the remaining raw materials except vegetable oil, trehalose, maltitol and egg liquid to obtain the second system; Mix the first system and the second system to obtain batter. Preferably, the obtained batter has a specific gravity of 0.55-0.6.

[0040] It is worth noting that in this application, the trehalose, maltitol and egg liquid are mixed and beaten first, so that the trehalose and maltitol can be fully mixed with the egg liquid during...

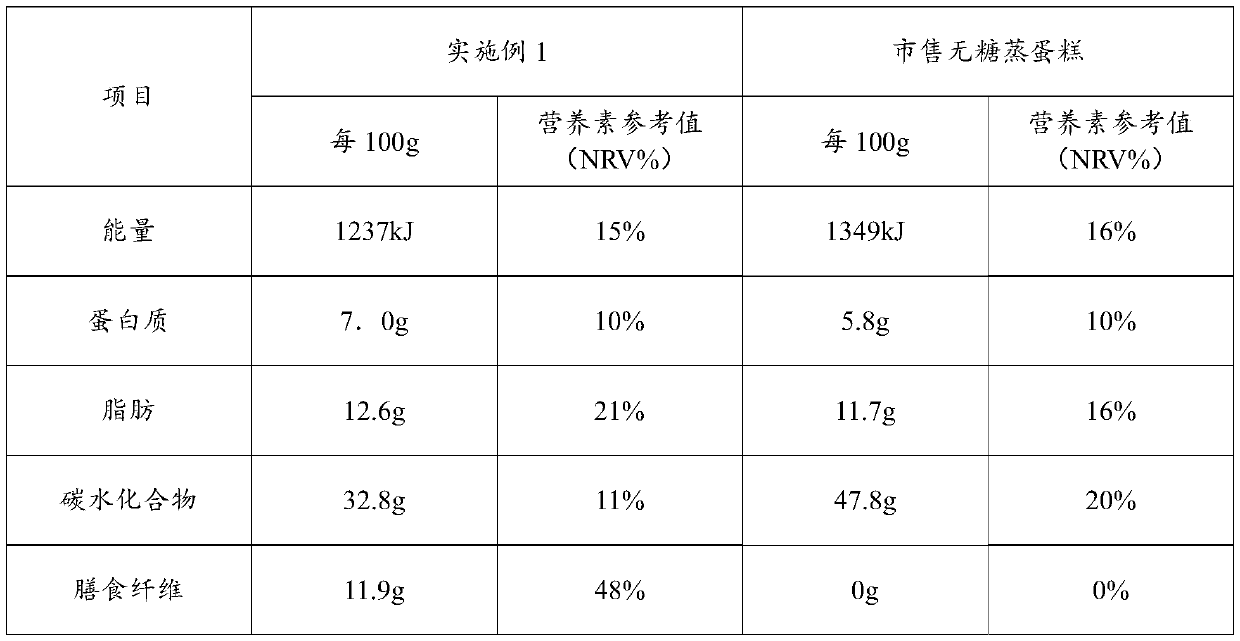

Embodiment 1

[0047] The raw material of the low GI steamed cake rich in dietary fiber provided by this embodiment consists of the following ingredients:

[0048] 10 parts by weight of trehalose, 2 parts by weight of maltitol, 6 parts by weight of soybean dietary fiber, 12 parts by weight of oat fiber, 2 parts by weight of wheat fiber, 1 part by weight of konjac flour, 3 parts by weight of polydextrose, 3 parts by weight of inulin, 2 parts by weight of resistant dextrin, 20 parts by weight of low-gluten wheat flour, 10 parts by weight of chickpea flour, 30 parts by weight of egg liquid, 10 parts by weight of vegetable oil, 1 part by weight of Composite emulsifying leavening agent, 10 parts by weight of water and 1 part by weight of salt.

[0049] Among them, the compound emulsifying leavening agent is composed of hydroxypropyl distarch phosphate, monoglyceride, polyglycerol fatty acid ester, sodium bicarbonate, guar Gum, xanthan gum and disodium dihydrogen pyrophosphate.

[0050] Its prep...

Embodiment 2

[0052] The difference between this embodiment and embodiment 1 is that the raw material of cake is made up of following composition:

[0053] 20 parts by weight of trehalose, 5 parts by weight of maltitol, 10 parts by weight of soybean fiber, 23 parts by weight of oat fiber, 3 parts by weight of wheat fiber group, 5 parts by weight of konjac flour, 10 parts by weight of polydextrose, 8 parts by weight of inulin, 5 parts by weight of resistant dextrin group, 40 parts by weight of low-gluten wheat flour, 20 parts by weight of chickpea flour, 50 parts by weight of egg liquid, 15 parts by weight of vegetable oil, 5 parts by weight of The compound emulsifying leavening agent of the compound, the water of 30 parts by weight and the salt of 5 parts by weight.

[0054] Among them, the compound emulsifying leavening agent is composed of hydroxypropyl distarch phosphate, monoglyceride, polyglycerol fatty acid ester, sodium bicarbonate, guar Gum, xanthan gum and disodium dihydrogen pyro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com