Anti-allergic hair dye and preparation method thereof

A hair dye, anti-allergic technology, applied in hair care, pharmaceutical formulations, cosmetic preparations, etc., can solve the problems of complex production, insufficient color fastness, poor dispersion stability, etc., and achieves increased dispersion and adhesion. Good black effect and strong adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

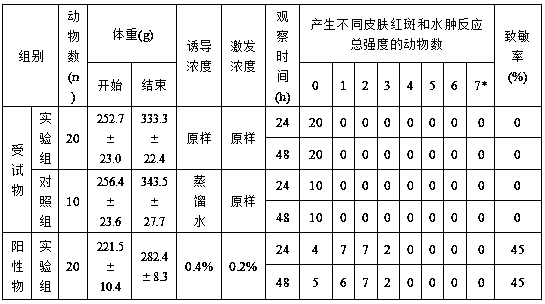

Method used

Image

Examples

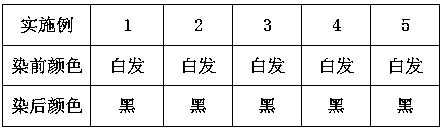

Embodiment 1

[0034] Anti-allergic hair dye in the present embodiment, by mass percentage 100%, is made up of following components:

[0035] Oxidation modified carbon black 0.5%,

[0036] Polymer material chitosan 4%,

[0037] Lemon Extract 2%,

[0038] The balance is deionized water.

[0039] Weigh the lemon extract (4g) of the prescription amount, add 30 parts by mass of deionized water (60g), heat to 40°C, stir until completely dissolved, then add the chitosan (8g) of the recipe amount, and stir for 20 Minutes later, add a prescription amount of oxidation-modified carbon black (1g), add deionized water to 100%, continue stirring for 30 minutes, cool to room temperature, and obtain a colloidal hair dye.

Embodiment 2

[0041] Anti-allergic hair dye in the present embodiment, by mass percentage 100%, is made up of following components:

[0042] Oxidation modified carbon black 0.5%,

[0043] Polymer material chitosan 4%,

[0044] Lemon Extract 2%,

[0045] Walnut Green Bark Extract 0.25%

[0046] The balance is deionized water.

[0047] Weigh the recipe amount of lemon extract (4g), add 30 parts by mass of deionized water (60g), heat to 40°C, and stir until completely dissolved. Add the walnut green husk extract (0.5g) and chitosan (8g) in sequence, stir for 20 minutes, then add the oxidation-modified carbon black (1g) in the recipe amount, then add deionized water to 100%, continue Stir for 30 minutes and cool to room temperature to obtain a colloidal hair dye.

Embodiment 3

[0049] Anti-allergic hair dye in the present embodiment, by mass percentage 100%, is made up of following components:

[0050] Oxidation modified carbon black 2%,

[0051] Polymer material chitosan 2%,

[0052] Lemon Extract 4%,

[0053] Walnut Green Bark Extract 1%

[0054] The balance is deionized water.

[0055] The specific preparation method of the anti-allergic hair dye of the present invention is as follows: weigh the lemon extract (8g) of the recipe, add 30 parts by mass of deionized water (60g), heat to 50°C, and stir until completely dissolved. Add the walnut green husk extract (2g) and chitosan (4g) in sequence, stir for 10 minutes, then add the oxidation-modified carbon black (4g) in the recipe amount, add deionized water to 100%, and continue stirring After 20 minutes, cool to room temperature to obtain a colloidal hair dye.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com