Carbon-based catalytic material and application thereof

A technology of catalytic materials and carbon-based catalysts, applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of high economic cost, achieve high degradation rate, simple and fast preparation method, save preparation cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] This embodiment is the preparation of carbon-based catalytic material and carbon-based catalyst

[0047] Dry the oil-containing scum, and then place it in a nitrogen atmosphere at 5°C / min to heat up to 400°C, 500°C, 600°C, and 700°C for 6 hours, and then obtain a carbon-based catalytic material after cooling;

[0048] Add the carbon-based catalytic material to 1mol / L hydrochloric acid for pickling to dissolve the metal on the surface of the carbon-based catalytic material, then wash it with pure water until neutral, and dry it at 70°C to obtain the carbon-based catalyst.

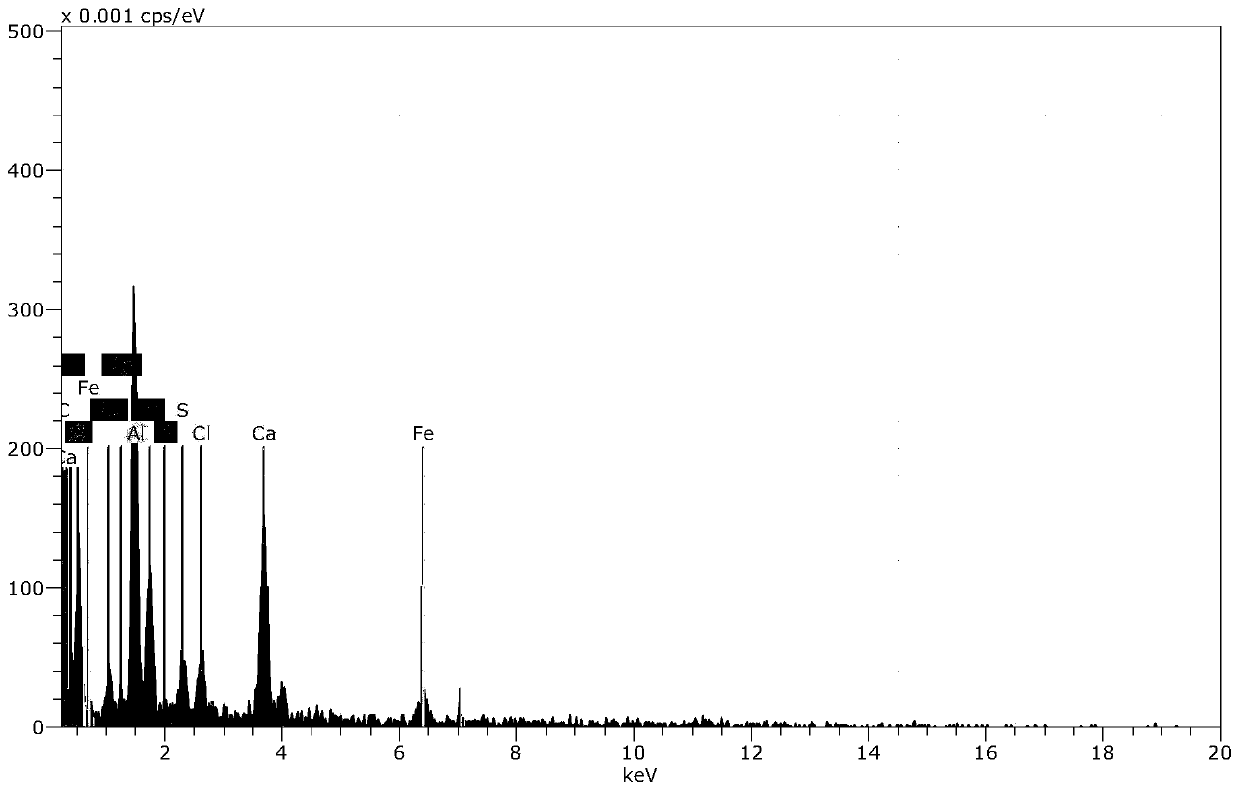

[0049] The carbon-based catalytic materials and carbon-based catalysts obtained by pyrolysis at 600 °C were selected for SEM and EDX characterization. figure 1 It is the SEM figure of the carbon-based catalytic material of the present embodiment, figure 2 It is the SEM figure of the carbon-based catalyst of this embodiment. Such as figure 1 and figure 2 As shown, carbon-based catalytic materials...

Embodiment 2

[0054] This example uses the carbon-based catalytic material provided in Example 1 to perform a degradation test on phenol

[0055] Choose respectively the carbon-based catalytic material of embodiment 1, choose 40ml, 50ppm phenol solution as target pollutant; With phenol, persulfate, carbon-based catalytic material mass ratio is 0.05:0.57:0.2; Take carbon-based catalytic material and add phenol solution Stir in medium, and add persulfate after adsorption equilibrium. All the reactions were carried out at a room temperature of 25° C.; the stirring rate was 500 r / min; the stirring time was 120 min.

[0056] Figure 5 It is a diagram of the degradation effect of carbon-based catalytic material activated peroxymonosulfate on phenol provided in Example 1 of the present invention. Such as Figure 5 As shown, within 80 minutes, the carbon-based catalytic material activates peroxymonosulfate to 40ml, and the removal rate of 50ppm phenol can reach 50%.

Embodiment 3

[0058] This embodiment uses the carbon-based catalysts provided in Example 1 and Comparative Example 1 to carry out degradation tests on phenol

[0059] Select the carbon-based catalyst of embodiment 1 and the carbon-based catalyst of comparative example 1 respectively, choose 40ml, 50ppm phenol solution as target pollutant; With phenol, persulfate, carbon-based catalyst mass ratio is 0.05:0.57:0.2; Weigh carbon-based Add the catalyst into the phenol solution and stir, and add persulfate after the adsorption equilibrium. All the reactions were carried out at a room temperature of 25° C.; the stirring rate was 500 r / min; the stirring time was 120 min.

[0060] Figure 6 It is a diagram of the degradation effect of phenol activated by the carbon-based catalyst activated peroxymonosulfate provided in Example 1 of the present invention. Such as Figure 6 As shown, within 40 minutes, the carbon-based catalyst activates peroxymonosulfate to 40ml, and the removal rate of 50ppm phe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com