Novel ultraviolet aging-resistant powder coating and preparation method thereof

A technology of powder coating and ultraviolet light, which is applied in the direction of powder coating, polyester coating, epoxy resin coating, etc., and can solve the problems of unsustainable protective effect, inability to play the role of ultraviolet light protection, affecting the appearance and mechanical properties of materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Weigh 2.14g of 4,4'-dihydroxybenzophenone and 1.84g of epichlorohydrin, mix them at 25°C, fill them with nitrogen protection gas, heat to 50°C and stir for 10 minutes, the system dissolves, become clarified. Then the temperature of the reaction system was raised to 70°C, under N 2 To react under protection, add 8 g of 30% NaOH aqueous solution dropwise with a constant pressure funnel, control heating to maintain the system temperature between 70°C and 90°C, and stop heating after 4 hours of reaction. Excess epichlorohydrin was distilled off under reduced pressure, and then the system was washed with deionized water, filtered, and dried to obtain a novel epoxy resin containing an ultraviolet light stabilizer. Productive rate 81.2%, reaction equation is as follows:

[0029]

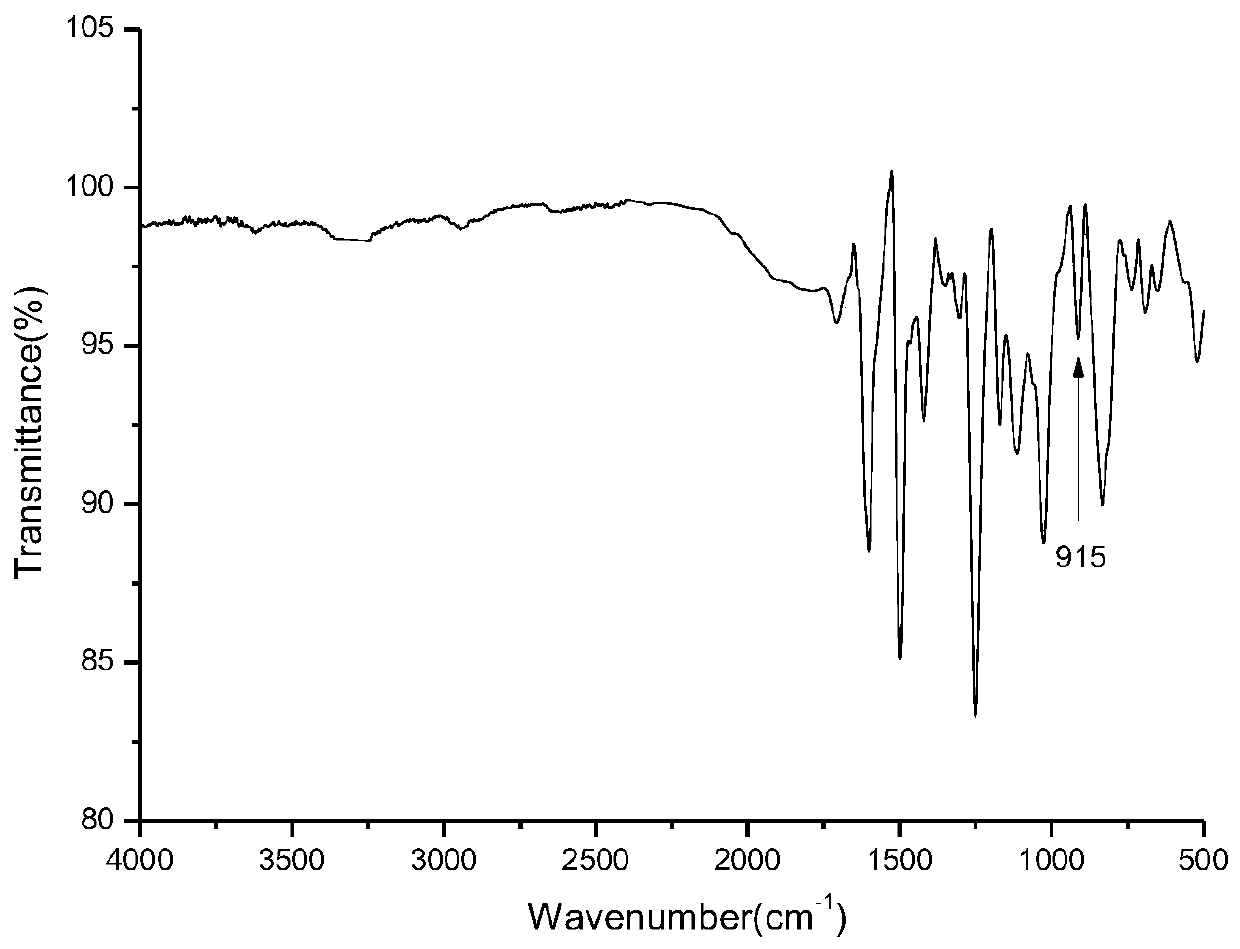

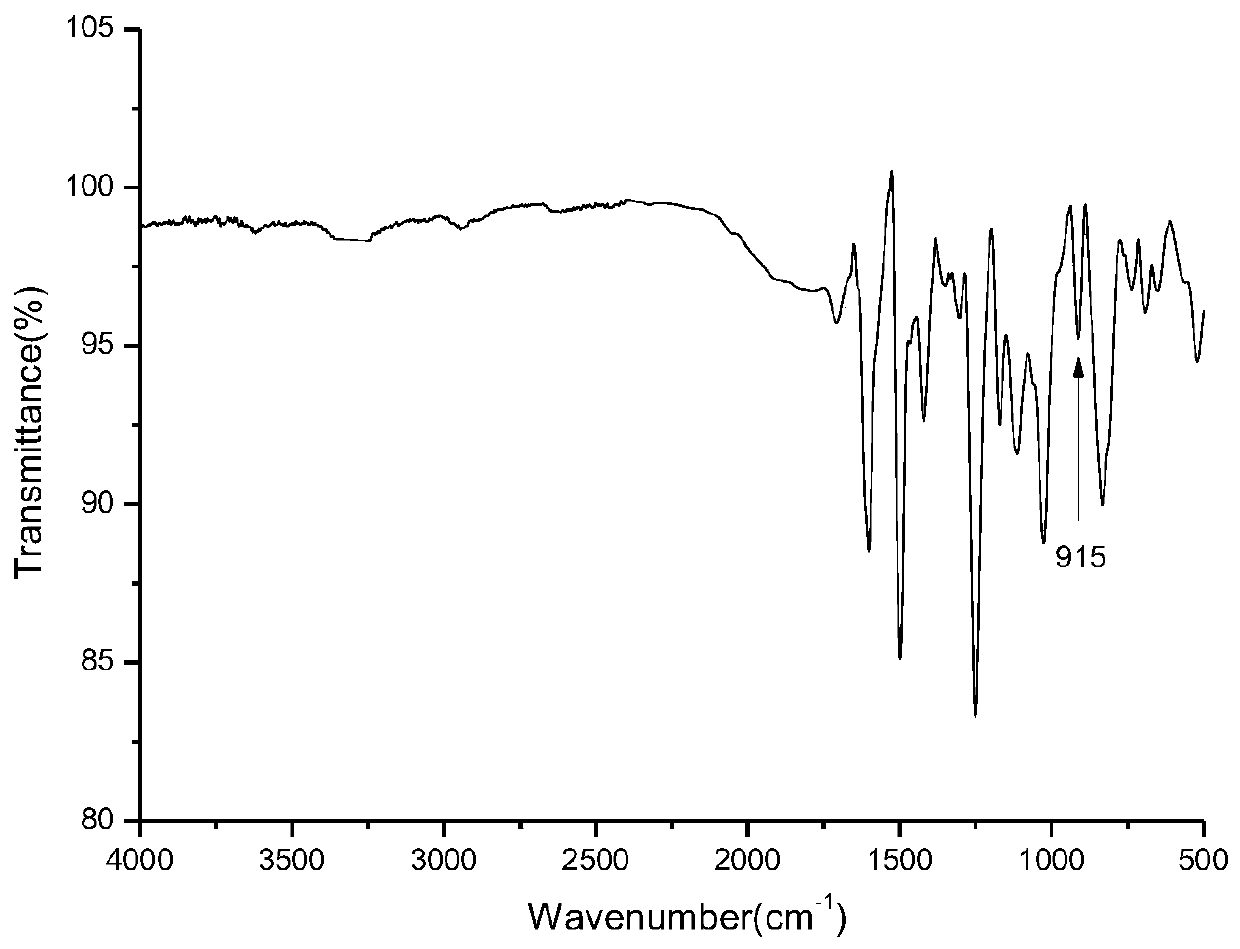

[0030] The infrared spectrogram of this product sees attached figure 1 , 915cm -1 The peak at indicates the formation of epoxy structures.

[0031] (2) Weigh 2g of the novel epoxy resin p...

Embodiment 2

[0034] The 4,4'-dihydroxybenzophenone in Example 1 is replaced by 4 hydroxybenzophenone, the amount of 4 hydroxybenzophenone added is changed to 1.98g, and 1.84g of epichlorohydrin is still 1.84g , the mass concentration is 30% NaOH aqueous solution changed to 7g. Except that the amount of reactant changes, other operating steps are the same as those in Example 1. Yield 84.7%.

[0035] The reaction equation of this example is as follows:

[0036]

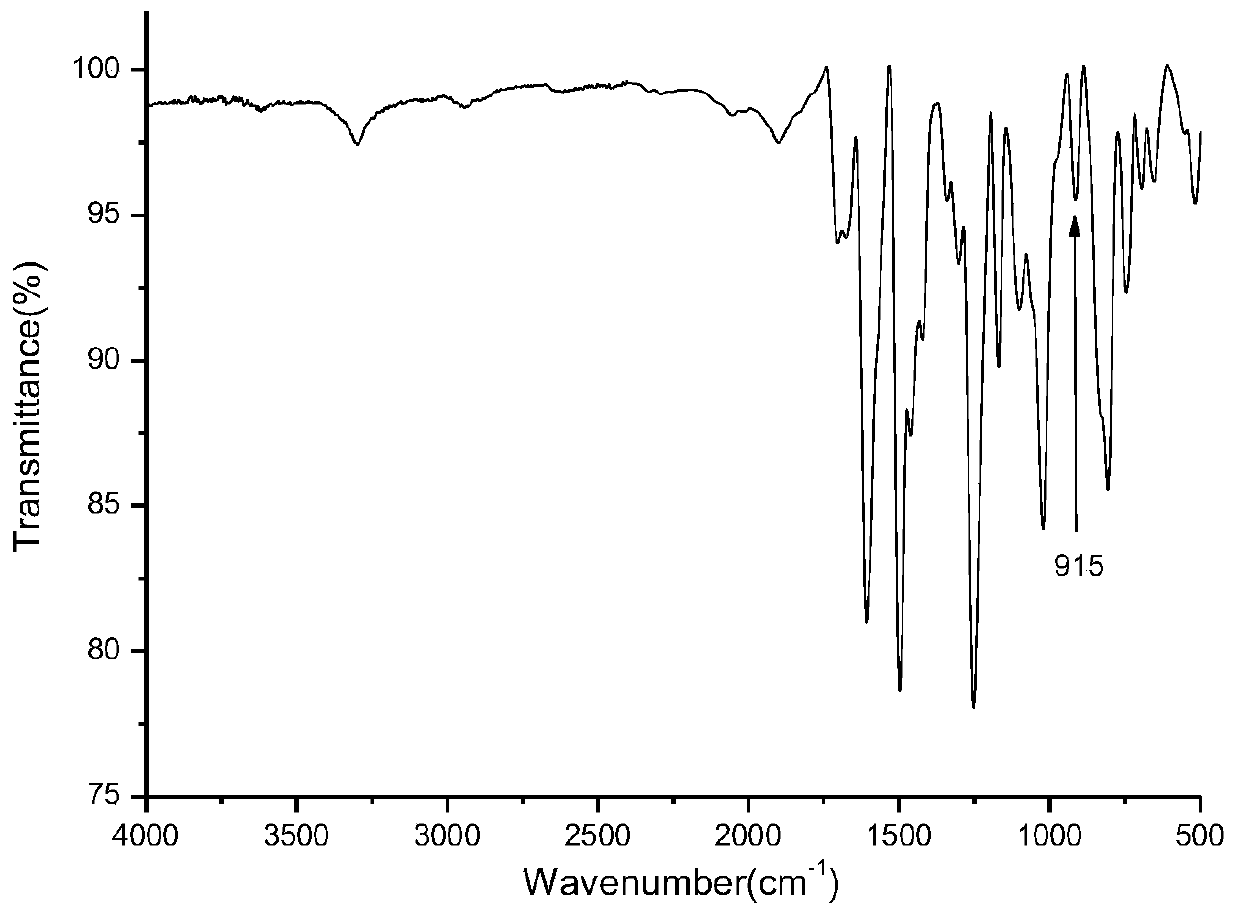

[0037] The infrared spectrogram of this product sees attached figure 2 , 915cm -1 The peak at indicates the formation of epoxy structures.

Embodiment 3

[0039] The 4,4'-dihydroxybenzophenone in Example 1 was replaced by 3,4-dihydroxybenzophenone. Except that the type of reactant was changed, other operating steps were the same as those in Example 1. Yield 71.7%.

[0040] The reaction equation of this example is as follows:

[0041]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com