Flame-retardant polypropylene barrier explosion-proof material, and preparation method and application thereof

A technology of blocking explosion-proof materials and flame-retardant polypropylene, which is applied in the field of fuel oil and gas barrier explosion-proof, which can solve the problems of reduced explosion suppression performance, non-flammable resistance, and difficult processing, etc., and achieve good barrier explosion-proof effect, good flame-retardant performance, and reasonable structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

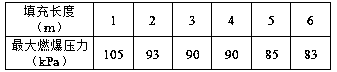

Embodiment 1

[0024] Embodiment 1, a flame-retardant polypropylene barrier explosion-proof material, the material is a porous network structure, which can divide the space into several small units; the ingredients include: 80 grams of polypropylene, 20 grams of halogen-free composite flame retardant, maleic anhydride Branch polypropylene (Dongguan Kangjin New Material Technology Co., Ltd., model: 9909) 5 grams, synergist 1 gram and conductive carbon black 1 gram;

[0025] The halogen-free composite flame retardant is composed of modified ammonium polyphosphate and high molecular weight polymerized triazine halogen-free flame retardant (Shouguang Lisheng Chemical Co., Ltd. model: 93058-67-4,) and the modified ammonium polyphosphate The weight ratio to the high molecular weight polymeric triazine halogen-free flame retardant is 4:1, wherein the modified ammonium polyphosphate is melamine-coated ammonium polyphosphate (Xu Sen Non-Halogen Smoke Suppressant Flame Retardant Co., Ltd., model: XS -...

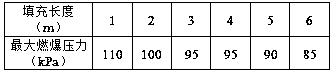

Embodiment 2

[0038] Embodiment 2, flame-retardant polypropylene barrier explosion-proof material, the material is a porous network structure, which can divide the space into several small units; the ingredients include: 75 grams of polypropylene, 25 grams of halogen-free composite flame retardant, maleic anhydride Branched polypropylene (source: Dongguan Kangjin New Material Technology Co., Ltd., model: 9909) 7 grams, synergist 2 grams and conductive carbon black 1.5 grams;

[0039] The halogen-free composite flame retardant is composed of modified ammonium polyphosphate and high molecular weight polymerized triazine halogen-free flame retardant (Shouguang Lisheng Chemical Co., Ltd. model: 93058-67-4,) and the modified ammonium polyphosphate The weight ratio to the high molecular weight polymeric triazine halogen-free flame retardant is 9:2, wherein the modified ammonium polyphosphate is melamine-coated ammonium polyphosphate (Xu Sen Non-Halogen Smoke Suppressant Flame Retardant Co., Ltd., ...

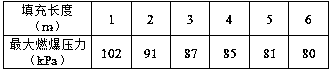

Embodiment 3

[0052] Embodiment 3, flame-retardant polypropylene barrier explosion-proof material, the material is a porous network structure, which can divide the space into several small units; the ingredients include: 70 grams of polypropylene, 30 grams of halogen-free composite flame retardant, maleic anhydride Branched polypropylene (Dongguan Kangjin New Material Technology Co., Ltd., model: 9909) 10 grams, synergist 3 grams and conductive carbon black 2 grams;

[0053] The halogen-free composite flame retardant is composed of modified ammonium polyphosphate and high molecular weight polymerized triazine halogen-free flame retardant (Shouguang Lisheng Chemical Co., Ltd. model: 93058-67-4,) and the modified ammonium polyphosphate The weight ratio to the high molecular weight polymeric triazine halogen-free flame retardant is 5:1, wherein the modified ammonium polyphosphate is melamine-coated ammonium polyphosphate (Xu Sen Non-Halogen Smoke Suppressant Flame Retardant Co., Ltd., model: XS...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com