A kind of method and sealing agent of anodized film pre-sealing

An anodizing film and anodizing technology, applied in anodizing, coating, surface reaction electrolytic coating, etc., can solve the problem of unable to pass acid-base test stably, difficult to ensure alkali resistance stability, loss of metal texture, etc. To achieve super hydrophobicity, excellent adhesion, improve the effect of hydrophobicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

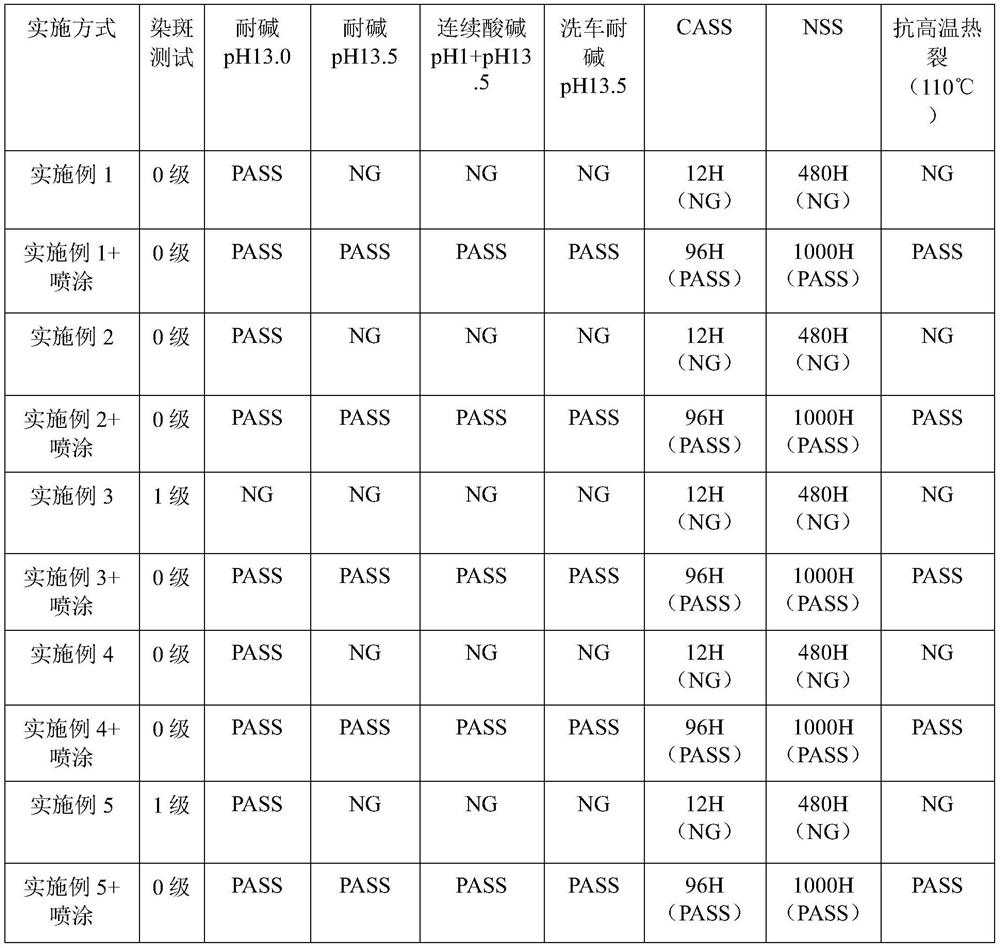

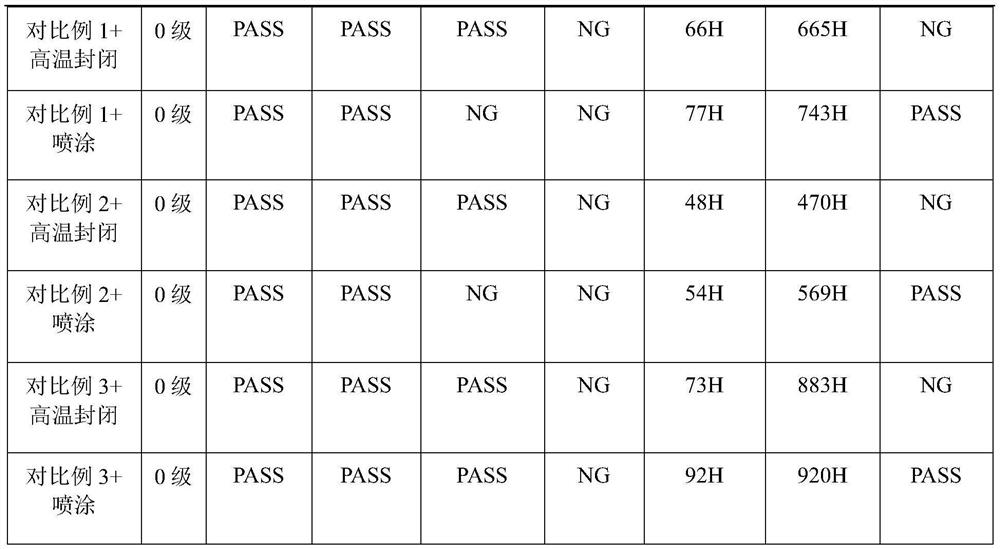

Examples

Embodiment 1

[0065]This example discloses a sealing agent of an anodized film pre-sealing hole, and the sealing agent comprises the following components:

[0066]Nickel acetate: 2g / L,

[0067]Fluorinated nickel: 3g / L,

[0068]Polyethylene glycol: 0.1g / L,

[0069]Lignin sulfonate: 0.1g / L,

[0070]Acetic acid: 0.05g / L,

[0071]Oxide oxide (single layer): 0.01 g / L,

[0072]Dodecanocyl sulfate: 0.05 g / L,

[0073]The solvent is pure water.

Embodiment 2

[0075]This example discloses a sealing agent for pre-sealing holes of anodized film, including the following components:

[0076]Nickel acetate: 5g / L,

[0077]Ammonium fluoride: 0.5g / L,

[0078]Sorbitol: 0.1g / L,

[0079]Methylene bisnaphthalene sodium sodium sodium sodium sodium sodium sodium - 0.15 g / L,

[0080]Acetic acid: 0.01g / L,

[0081]Oxide oxide (single layer): 0.03 g / L,

[0082]Alkylphenol polyoxyethylene ether: 0.1 g / L,

[0083]The solvent is pure water.

Embodiment 3

[0085]This example discloses a sealing agent of the pre-sealing hole of the anodized film, including the following components:

[0086]Fluorinated nickel: 4g / L,

[0087]Sodium fluoride: 0.5g / L,

[0088]Polyethylene glycol: 0.3g / L,

[0089]Sodium methylene bisnaphthalene sulfate: 0.2g / L,

[0090]Acetic acid: 0.02g / L,

[0091]Oxide oxide (single layer): 0.1 g / L,

[0092]Fat alcohol polyoxyethylene ether: 0.5g / L,

[0093]The solvent is pure water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com