Environment-friendly inflatable puffed food packaging film

A technology of puffed food and packaging film, applied in packaging, wrapping paper, transportation and packaging, etc., can solve the problems of losing the crispy taste of puffed food, failing to meet the requirements of barrier properties, and lacking biodegradation properties, etc. The effect of increasing the barrier properties and increasing the density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

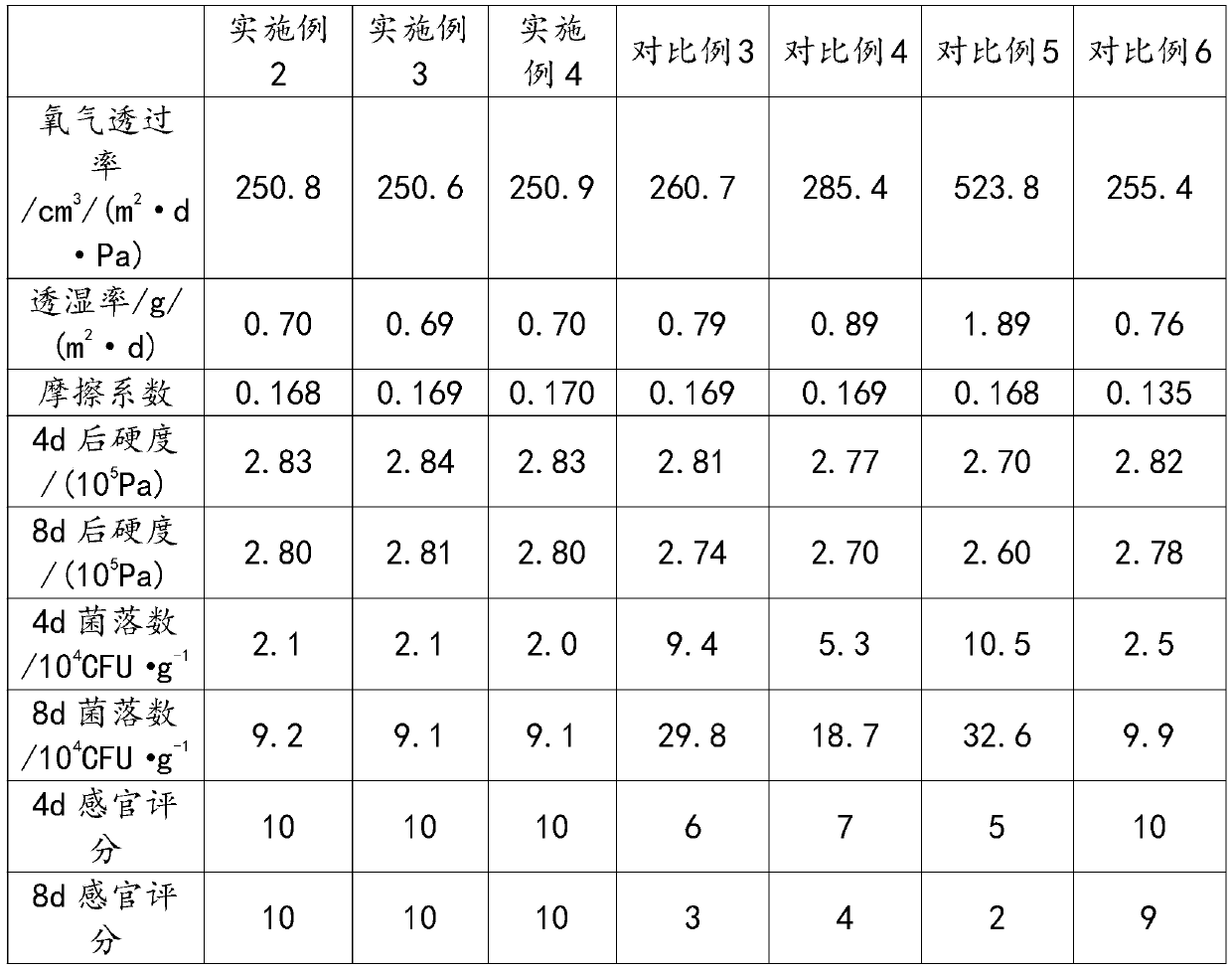

Examples

Embodiment 1

[0041] Modified graphene oxide is made by the following methods:

[0042] (1) Ultrasonic disperse 0.3g of graphene oxide in 300mL of DMF (N,N-dimethylformamide), add 112g of potassium fluoride and 15g of potassium iodide, stir evenly, raise the temperature to 100°C, and continuously drop 40mL of ring Oxychloropropane, reflux for 15 hours, centrifuge, and wash the product repeatedly with ethanol and deionized water 5-7 times to obtain a slurry;

[0043] (2) Weigh 4.5g of polyvinylpyrrolidone and add it to 22mL of the above slurry, stir magnetically for 6h, then add 7.2mL of AgNO 3 Aqueous solution (mass concentration: 31.93 / L) was quickly added to the above solution, stirred for 6 minutes, then the mixture was heated to 60°C and kept for 2 days, the reaction product was centrifuged at 8000r / min, washed 6-7 times with deionized water, Vacuum drying to obtain modified graphene oxide.

Embodiment 2

[0049] An environment-friendly inflatable puffed food packaging film, comprising sequentially compounded wear-resistant TPU layer, non-woven fabric layer and heat-sealing layer;

[0050] The packaging film is made by the following steps:

[0051] The first step is to add water-based polyurethane to deionized water, stir until dissolved, add modified graphene oxide, first stir at room temperature for 20 minutes, and then ultrasonically for 10 minutes to prepare a heat-sealing layer coating;

[0052] The heat-sealing layer coating is made of 30 parts of water-based polyurethane, 2 parts of modified graphene oxide, and 20 parts of deionized water;

[0053] The second step is to soak the non-woven fabric in an aqueous ethanol solution (60% mass fraction) for 180 minutes, then transfer to an oscillator and vibrate for 60 minutes to remove residual impurities on the surface of the non-woven fabric, and then rinse it repeatedly with deionized water for 3 times , remove residual etha...

Embodiment 3

[0059] An environment-friendly inflatable puffed food packaging film, comprising sequentially compounded wear-resistant TPU layer, non-woven fabric layer and heat-sealing layer;

[0060] The packaging film is made by the following steps:

[0061] The first step is to add water-based polyurethane to deionized water, stir until dissolved, add modified graphene oxide, first stir at room temperature for 25 minutes, and then ultrasonically for 10 minutes to prepare a heat-sealing coating;

[0062] The heat-sealing layer coating is made of 35 parts of water-based polyurethane, 2.5 parts of modified graphene oxide, and 25 parts of deionized water;

[0063] The second step is to soak the non-woven fabric in an aqueous ethanol solution (60% by mass) for 180 minutes, then transfer to an oscillator and vibrate for 60 minutes to remove residual impurities on the surface of the non-woven fabric, and then rinse it repeatedly with deionized water for 3- 4 times to remove residual ethanol, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com