Electrolyte with self-repairing function and preparation method of solid-state battery

A technology of solid-state batteries and composite electrolytes, applied in the manufacture of electrolyte batteries, non-aqueous electrolyte batteries, solid electrolytes, etc., can solve problems such as thermal runaway, reduced energy storage and release stability, and shortened device life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The invention discloses a method for preparing an electrolyte with a self-repairing function and a solid-state battery, comprising the following steps:

[0029] Step 1. Dissolve vinyltriethoxysilane (VTES) in deionized water, ultrasonically hydrolyze it completely, add ammonia water drop by drop, form a gel, separate, purify and dry to obtain the solid product vinyl functionalized dioxide Silicon, which acts as a cross-linking active site;

[0030] Step 2, blending and dissolving vinyl functionalized silica, self-repairing functionalized group compound, ion-conducting group compound, initiator, inorganic conductive ceramics and lithium salt in a solvent according to the proportion, fully dispersing and mixing to obtain Precursor solution; the precursor solution is cast into a film, reacted at a certain temperature, and then dried to obtain a self-healing functional composite electrolyte;

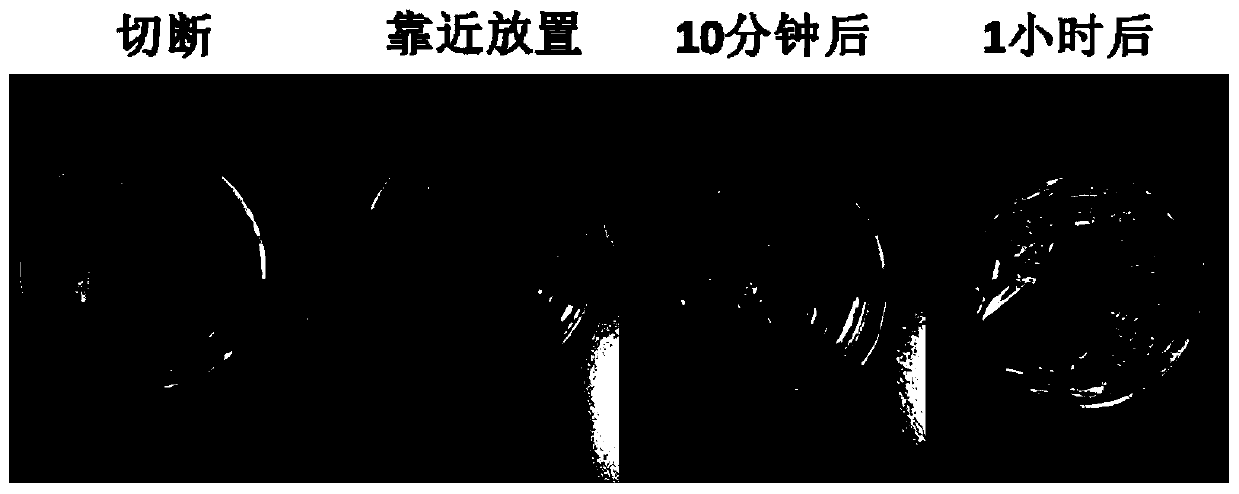

[0031] Step 3, the self-repairing functional composite electrolyte is matched wi...

Embodiment 1

[0047] (1) Preparation of vinyl functionalized silica

[0048] Add 4g of vinyltriethoxysilane to 32g of deionized water and stir continuously for 48 hours until the small droplets of triethoxymethylsilane completely disappear, then add 4ml of ammonia water with a concentration of 25% to the above solution dropwise , continuously stirred for 24 hours until the sol-gel reaction was complete. Use a high-speed centrifuge to centrifuge to obtain white powdery particles, then wash with ethanol several times to remove residual precursors and impurities, and finally dry the obtained white powder in a vacuum oven at 50°C to obtain vinyl Functionalized silica for later use.

[0049] (2) Preparation of hydrogen-bonded self-healing composite electrolyte and solid-state battery

[0050] Add 2 g of 6-methylisocytosine into 50 ml of DMSO, and stir at 150° C. for 10 minutes. The solution was cooled to room temperature, 2.64 g of methyl 2-isocyanate methacrylate was added to the above solut...

Embodiment 2

[0053] (1) Preparation of vinyl functionalized silica

[0054] Add 3g of vinyltriethoxysilane to 25g of deionized water and stir continuously for 48h until the small droplets of triethoxymethylsilane completely disappear, then add 5ml of ammonia water with a concentration of 25% to the above solution dropwise , continuously stirred for 24 hours until the sol-gel reaction was complete. Use a high-speed centrifuge to centrifuge to obtain white powdery particles, then wash with ethanol several times to remove residual precursors and impurities, and finally dry the obtained white powder in a vacuum oven at 50°C to obtain vinyl Functionalized silica for later use.

[0055] (2) Preparation of hydrogen-bonded self-healing composite electrolyte and solid-state battery

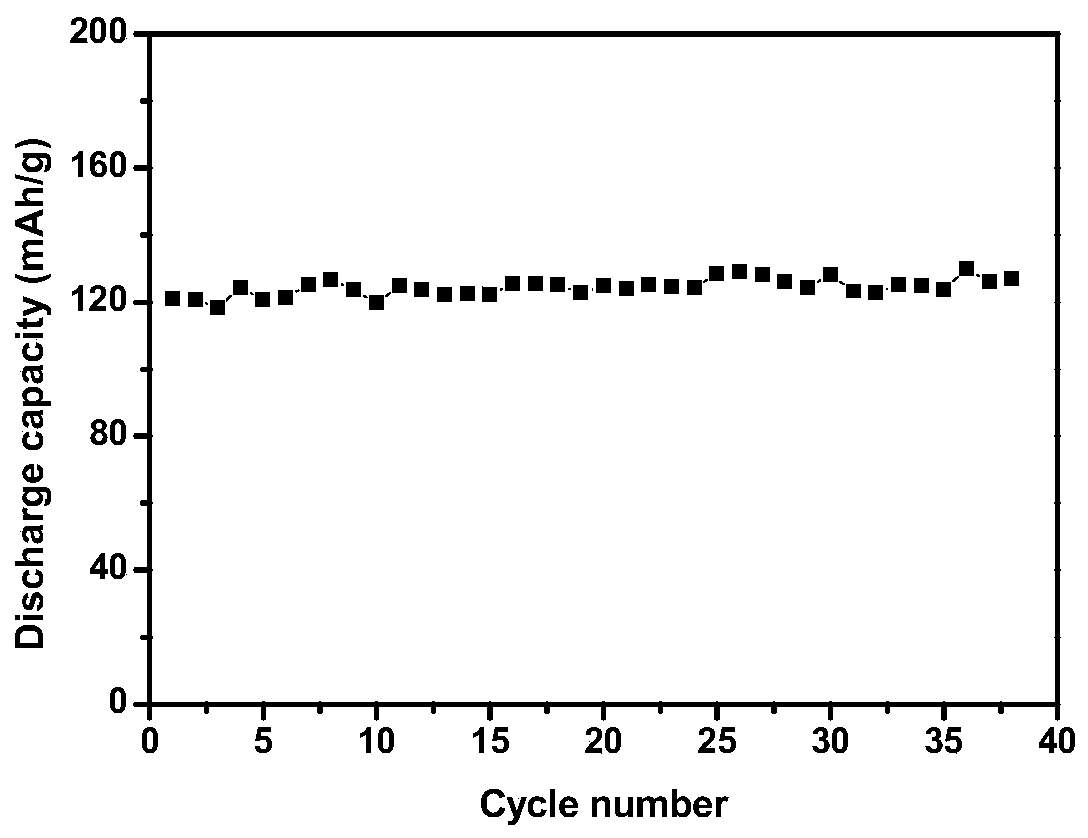

[0056] 0.8g of vinyl-functionalized silica, 8g of acrylic acid, 1g of LLTZO, 1g of LiFSI, and 0.01g of AIBN were magnetically stirred at room temperature, mixed evenly, cast into a film, and then reacted at 60°C for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com