Solid beverage containing probiotic composition and preparation method thereof

A technology of solid beverages and compositions, which is applied in the direction of food ingredients containing natural extracts, food ingredients containing sugar, food ingredients containing oligosaccharides, etc., and can solve the problem of probiotics that are not very well known and the application of probiotics in the product line It is not very extensive, the survival rate is difficult and other problems, to achieve the effect of protecting gastric mucosa, maintaining gastrointestinal health, and relieving stomach pain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

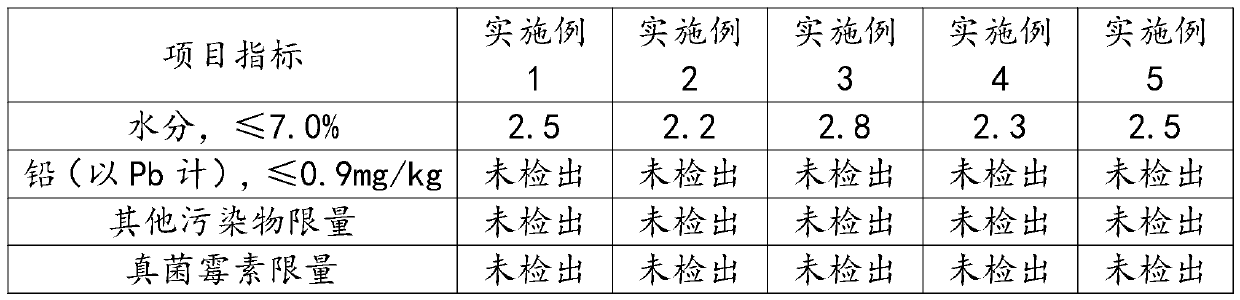

Embodiment 1

[0043]A solid beverage containing a probiotic composition is made from the following raw materials: 800 g of isomaltulose, 480 g of soybean protein powder, 200 g of xylitol, and 180 g of a probiotic composition (wherein, 100 g of Lactobacillus helveticus and 80 g of Lactobacillus plantarum ), sweet orange juice powder 80g, stachyose 80g, sweet orange essence 35g, monk fruit powder 15g and broccoli seed aqueous extract 1g.

[0044] Preparation:

[0045] (1) Raw material processing: pass xylitol through a 30-mesh sieve, and set aside; crush isomaltulose, pass through a 30-mesh sieve, set aside; mix isomaltulose, soybean protein powder, sweet orange juice powder and stachyose 70 ℃ dried to below 3% moisture, cooled to 18 ℃ and passed through a 30-mesh sieve for later use;

[0046] (2) Weighing: take each raw material by the weight of the above-mentioned solid beverage containing the probiotic composition;

[0047] (3) Mixing: firstly mix sweet orange essence, Luo Han Guo powder...

Embodiment 2

[0049] A solid beverage containing a probiotic composition is made from the following raw materials: 820 g of isomaltulose, 500 g of soybean protein powder, 200 g of xylitol, and 190 g of a probiotic composition (wherein, 100 g of Lactobacillus helveticus and 80 g of Lactobacillus plantarum , Bifidobacterium longum 10g), sweet orange juice powder 90g, stachyose 90g, sweet orange essence 38g, monk fruit powder 18g and broccoli seed aqueous extract 3g.

[0050] Preparation:

[0051] (1) Raw material processing: pass xylitol through a 40-mesh sieve, and set aside; crush isomaltulose, pass through a 40-mesh sieve, set aside; mix isomaltulose, soybean protein powder, sweet orange juice powder and stachyose 70 ℃ dried to below 3% moisture, cooled to 20 ℃ and passed through a 40-mesh sieve for later use;

[0052] (2) Weighing: take each raw material by the weight of the above-mentioned solid beverage containing the probiotic composition;

[0053] (3) Mixing: firstly mix sweet orang...

Embodiment 3

[0055] The solid beverage containing the probiotic composition is made from the following raw materials: 828g isomaltulose, 500g soybean protein powder, 207g xylitol, 200g probiotic composition (wherein, Lactobacillus helveticus 100g, Lactobacillus plantarum 80g , Bifidobacterium longum 10g, Bifidobacterium animalis 10g), sweet orange juice powder 100g, stachyose 100g, sweet orange flavor 40g, Luo Han Guo powder 20g and broccoli seed water extract 5g.

[0056] Preparation:

[0057] (1) Raw material processing: pass xylitol through a 50-mesh sieve, and set aside; crush isomaltulose, pass through a 50-mesh sieve, set aside; mix isomaltulose, soybean protein powder, sweet orange juice powder and stachyose 75 ℃ dried to below 3% moisture, cooled to 20 ℃ and passed through a 50-mesh sieve for later use;

[0058] (2) Weighing: take each raw material by the weight of the above-mentioned solid beverage containing the probiotic composition;

[0059] (3) Mixing: firstly mix sweet oran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com