Composite humic acid sponge bionic soil matrix and preparation method and application thereof

A kind of humic acid and composite technology, applied in the direction of planting substrate, botanical equipment and methods, application, etc., can solve the problems of difficult to promote plant root growth and nutrients, difficult to collect natural rainwater, difficult to meet the requirements, etc., to facilitate transportation and Storage, low cost, effect of particle size reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0039] Under alkaline conditions, after dissolving 3 parts of humic acid in 30 parts of water, add 0.4 parts of zinc stearate and sodium dodecylbenzene sulfonate with a mass ratio of 1:1, at 65 °C at 500 r / After stirring at a speed of 30 min, the modified humic acid was obtained after suction filtration, water washing, and drying at 80°C.

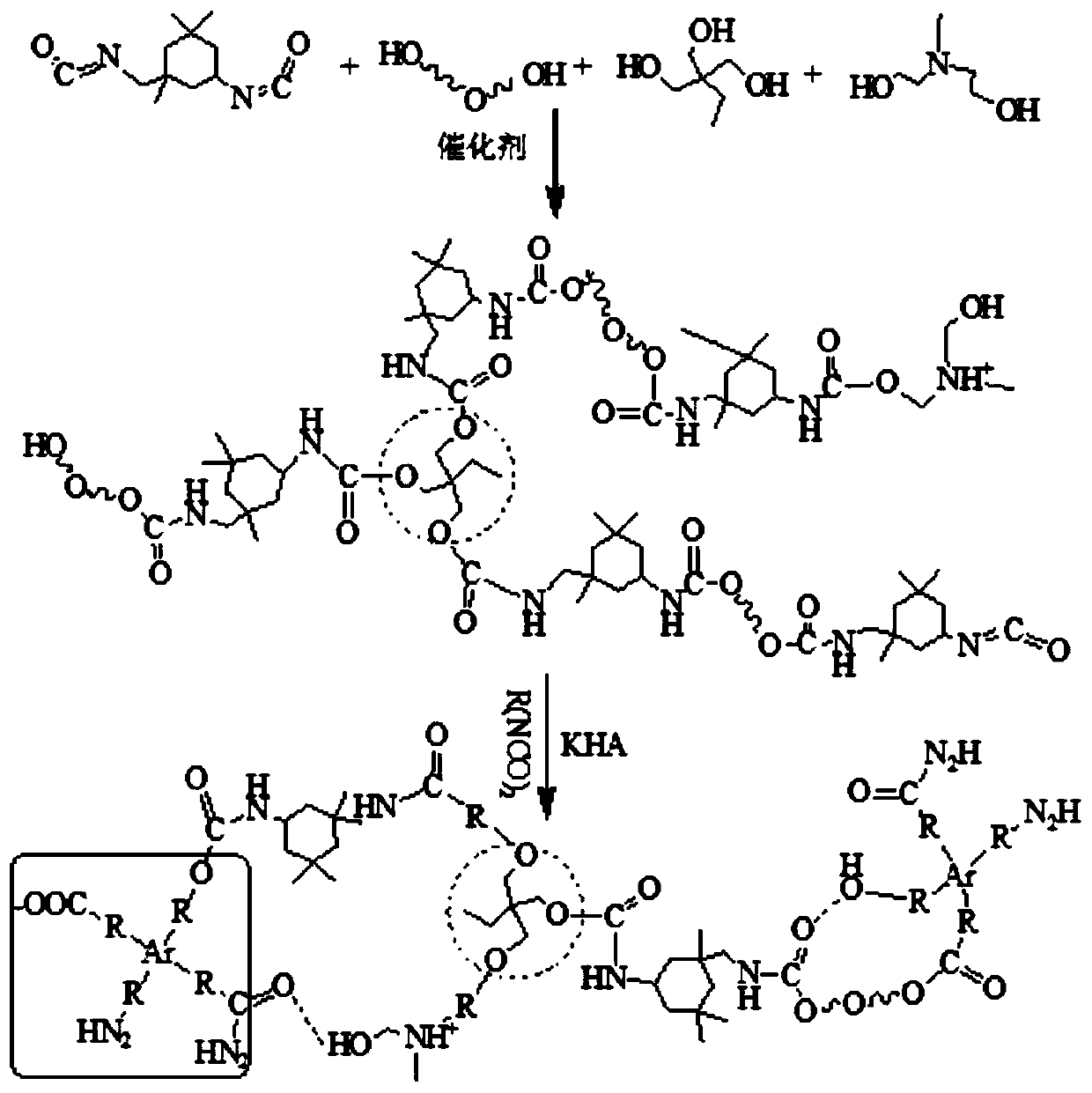

[0040] 1 part of the modified humic acid solution with a mass concentration of 15% and 0.8 part of isophorone diisocyanate (IPDI) prepared from the above-mentioned modified humic acid were respectively weighed as foaming agents for later use. Add 6 parts of polytetrahydrofuran, 18 parts of N-methylpyrrolidone, 0.3 parts of dibutyltin dilaurate, 0.5 parts of trimethylolpropane and 0.8 parts of N-methyldiethanolamine into a dry three-necked flask, and place in a water bath at 65 °C Stir for 10 minutes to fully dissolve, turn on the stirring device and raise the temperature to 75°C at a rate of 2°C / min, drop in 4 parts of IPDI at a rate of 1 ...

Embodiment 3

[0042] Under alkaline conditions, after dissolving 3 parts of humic acid in 30 parts of water, add 0.4 parts of zinc stearate and sodium lauryl sulfate with a mass ratio of 1:1, at 60°C at 500r / min After stirring at a high speed for 30 minutes, the modified humic acid was obtained by suction filtration, washing with water, and drying at 80°C.

[0043] Weigh 2 parts of the modified humic acid solution with a mass concentration of 15% and 1 part of isophorone diisocyanate (IPDI) prepared from the above-mentioned modified humic acid as foaming agent for later use. Add 8 parts of polytetrahydrofuran, 20 parts of N-methylpyrrolidone, 0.4 parts of dibutyltin dilaurate, 0.7 parts of trimethylolpropane and 1 part of N-methyldiethanolamine into a dry three-necked flask, at 65 °C Stir in a water bath for 10 minutes to fully dissolve, turn on the stirring device and raise the temperature to 75°C at a rate of 3°C / min, drop in 5 parts of IPDI at a rate of 1 drop / s, stir for 2 hours until t...

Embodiment 4

[0045] Under alkaline conditions, dissolve 4 parts of humic acid in 40 parts of water, add 0.3 parts of sodium lauryl sulfate, stir at 500 r / min for 30 minutes at 65 ° C, then wash with suction and wash at 80 ° C The modified humic acid was obtained after drying under the lower temperature.

[0046] Weigh 2 parts of the modified humic acid solution with a mass concentration of 10% and 0.8 parts of IPDI prepared from the above-mentioned modified humic acid as foaming agents for later use. Add 5 parts of polytetrahydrofuran, 15 parts of N-methylpyrrolidone, 0.3 parts of dibutyltin dilaurate, 0.5 parts of trimethylolpropane and 0.8 parts of N-methyldiethanolamine into a dry three-necked flask, at 65 °C Stir in a water bath for 10 minutes to fully dissolve, turn on the stirring device and raise the temperature to 75°C at a rate of 2°C / min, drop in 5 parts of isophorone diisocyanate at a rate of 1 drop / s, and stir for 2 hours until the system becomes Pale yellow and slightly visco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com