Wear-resistant non-slip rubber for soles and preparation method thereof

An anti-slip technology for shoe soles, which is applied in the field of rubber sole materials, can solve the problems that the wear resistance and anti-slip properties are difficult to meet the needs of use at the same time, achieve outstanding wear resistance and anti-slip properties, wide application range, and improve wear resistance The effect of sex and anti-slip

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

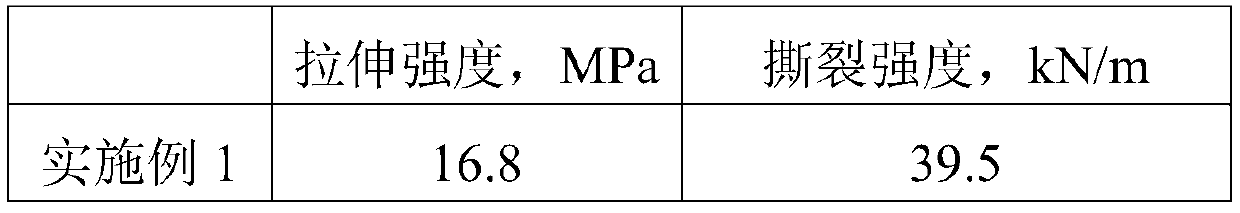

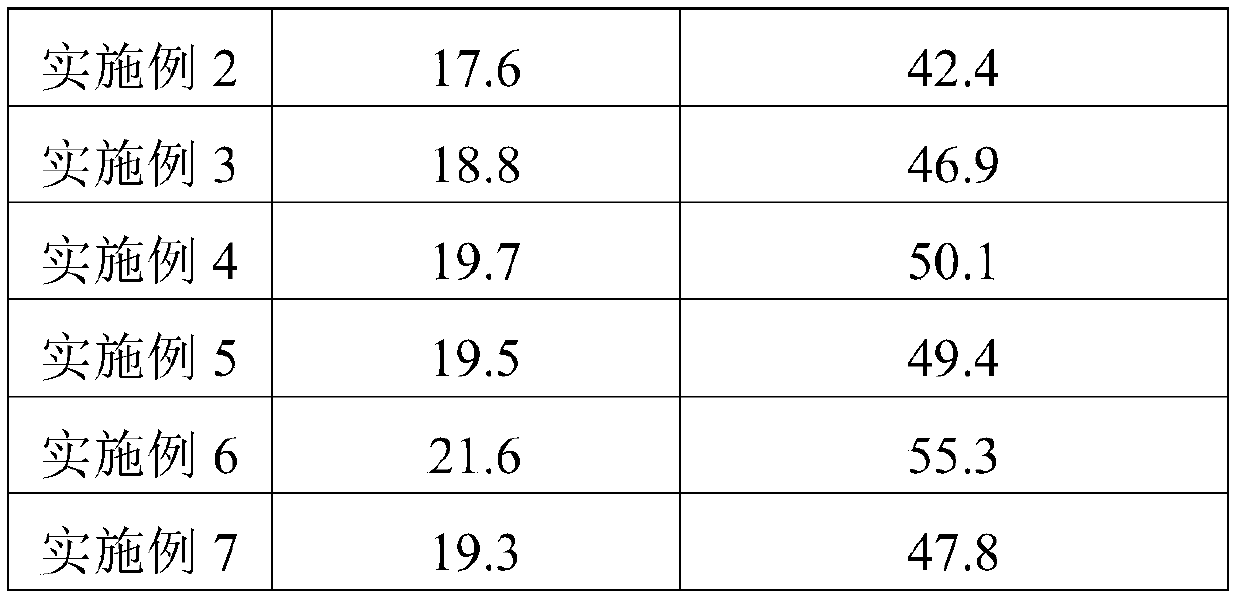

Examples

Embodiment 1

[0051] The raw material (parts by weight) of wear-resistant anti-slip rubber for soles: 40 parts of butyl rubber, 45 parts of butadiene rubber, 15 parts of natural rubber, 10 parts of meerschaum, 5 parts of softening oil, 5 parts of white carbon black, wear-resistant 4 parts of additives, 3 parts of dibutyl phthalate, 3 parts of accelerator, 3 parts of sulfur, 2 parts of zinc oxide, 2 parts of antioxidant, 1 part of stearic acid.

[0052] The accelerator is tetrabenzylthiuram disulfide.

[0053] The anti-aging agent is anti-aging agent MB.

[0054] The wear-resistant additive is titanium nitride.

[0055] The preparation method of wear-resistant anti-skid rubber for the sole comprises the following steps:

[0056] (1) Weigh each raw material by weight, add butyl rubber, cis-butadiene rubber, and natural rubber into the internal mixer, mix at 90°C for 6 minutes, then add sepiolite, softening oil, white carbon black, Grinding additives, dibutyl phthalate, zinc oxide, anti-agi...

Embodiment 2

[0059] The raw material (parts by weight) of wear-resistant anti-slip rubber for soles: 40 parts of butyl rubber, 45 parts of butadiene rubber, 15 parts of natural rubber, 10 parts of modified sepiolite, 5 parts of softening oil, 5 parts of white carbon black, 4 parts of wear-resistant additive, 3 parts of dibutyl phthalate, 3 parts of accelerator, 3 parts of sulfur, 2 parts of zinc oxide, 2 parts of anti-aging agent, 1 part of stearic acid.

[0060] The accelerator is tetrabenzylthiuram disulfide.

[0061] The anti-aging agent is anti-aging agent MB.

[0062] The modified sepiolite is prepared by the following method, wherein the parts are parts by weight: add 15 parts of sepiolite to 85 parts of water, ultrasonically disperse at 25°C for 30 minutes, and the ultrasonic frequency is 30kHz to obtain sepiolite dispersed solution, add 4 parts of KH570 to 15 parts of ethanol, stir at 150 rpm for 10 minutes to obtain a coupling agent ethanol solution, add the coupling agent ethano...

Embodiment 3

[0068] The raw material (parts by weight) of wear-resistant anti-slip rubber for soles: 40 parts of butyl rubber, 45 parts of butadiene rubber, 15 parts of natural rubber, 10 parts of modified sepiolite, 5 parts of softening oil, 5 parts of white carbon black, 4 parts of wear-resistant additive, 3 parts of dibutyl phthalate, 3 parts of accelerator, 3 parts of sulfur, 2 parts of zinc oxide, 2 parts of anti-aging agent, 1 part of stearic acid.

[0069] The accelerator is tetrabenzylthiuram disulfide.

[0070] The anti-aging agent is anti-aging agent MB.

[0071] The modified sepiolite is prepared by the following method, wherein the parts are parts by weight:

[0072] (1) Add 15 parts of sepiolite to 85 parts of water, ultrasonically disperse at 25°C for 30 minutes, and the ultrasonic frequency is 30kHz to obtain a sepiolite dispersion, add 4 parts of KH570 to 15 parts of ethanol at 150 rpm Stir for 10 minutes to obtain the ethanol solution of the coupling agent, add the ethan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com