A kind of permeable regenerated sand-mist seal layer material and preparation method thereof

A mist seal material and permeability technology, which is applied in the field of permeable regenerated sand mist seal material and its preparation, can solve the problems of low bonding strength and poor permeability of asphalt base surface, so as to improve service life and restore performance , Improve the effect of wear resistance and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

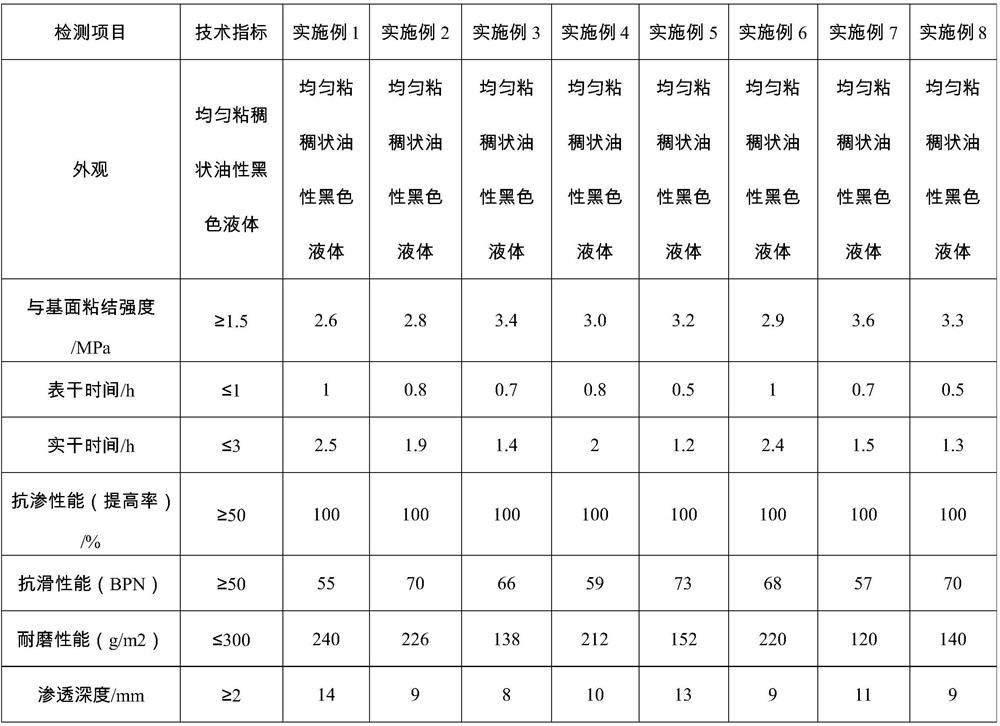

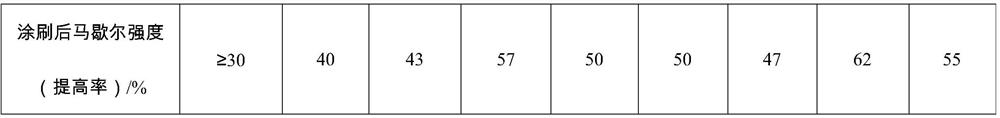

Examples

Embodiment 1

[0065] The permeable recycled sand-mist sealant material is prepared by the following steps:

[0066] (1) Add 1000kg of xylene into the stainless steel electrothermal reaction kettle, turn on the temperature to heat, and when the temperature rises to 70°C, add 150kg of rock asphalt particles and 30kg of aromatic oil regenerant and stir for 0.5h, and then add Slowly add 100kg of methyl acrylate, 30kg of styrene, 70kg of 2-methyl methacrylate, and 5kg of benzoyl peroxide catalyst dropwise into the reactor, and control the dropping time to 0.5h. After stirring and reacting for 1 hour, cool to room temperature to prepare the main material of the permeable and regenerated sand-mist seal layer;

[0067] (2) 20 mesh quartz sands of 1000 kg of step (1) prepared permeability regenerated seal layer containing sand, 10 kg of SBR thickener, 10 kg of modified dimethyl siloxane, 200 kg of quartz sand at high speed Stir in a disperser for 15 minutes and then mix to obtain the permeable rege...

Embodiment 2

[0069] The permeable recycled sand-mist sealant material is prepared by the following steps:

[0070] (1) Add 1000kg of S-1000 aromatic solvent oil into the stainless steel electric heating reaction kettle, turn on the temperature and heat, wait until the temperature rises to 80°C, add 300kg of petroleum hard asphalt particles, 70kg of naphthenic oil regeneration agent and stir for 1 hour , then slowly add 150kg of methyl acrylate, 45kg of styrene, 100kg of 2-methyl methacrylate, and 7kg of diethylpropylbenzene peroxide catalyst dropwise in the reactor, and control the dropping time for 0.6h, etc. After the addition, continue to stir and react for 1.5 hours, then cool to room temperature, and prepare the main material of the permeable regenerated sand mist seal layer;

[0071] (2) The 60 mesh corundum of 1000kg step (1) prepared permeable regenerated sand mist seal layer main material, 30kg SIS thickener, 30kg silicone modified polysiloxane wear resistance aid, 400kg Stir in ...

Embodiment 3

[0073] The permeable recycled sand-mist sealant material is prepared by the following steps:

[0074] (1) Add 1000kg of S-1500 aromatic hydrocarbon solvent oil into the stainless steel electric heating reaction kettle, turn on the temperature and heat, wait until the temperature rises to 75°C, add 200kg of coal tar pitch particles, 50kg of aromatic hydrocarbon oil regenerant and stir for 0.5h, then Slowly add 200kg of methyl acrylate, 60kg of styrene, 140kg of 2-methyl methacrylate, and 10kg of diethylpropylbenzene peroxide catalyst dropwise into the reactor, and control the dropping time to 0.6h. Then continue to stir and react for 2 hours and then cool to room temperature to prepare the main material of the permeable regenerated sand mist-containing seal layer;

[0075] (2) 1000kg of the permeable regenerated sand mist sealant main material prepared by step (1), 50kg of SEBS thickener, 30kg of polyester modified polysiloxane abrasion resistance additive, 300kg of 40 mesh qua...

PUM

| Property | Measurement | Unit |

|---|---|---|

| penetration depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com