A kind of method and system for heavy oil production of light olefins and light aromatics

A low-carbon olefin and heavy oil technology, which is applied in the direction of hydrocarbon cracking, hydrocarbon oil treatment, petroleum industry, etc., can solve the problems of high energy consumption of steam cracking, low yield of naphtha fraction, and low-carbon olefin production, etc., to achieve Improve economic and social benefits, promote transformation and development, and increase productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

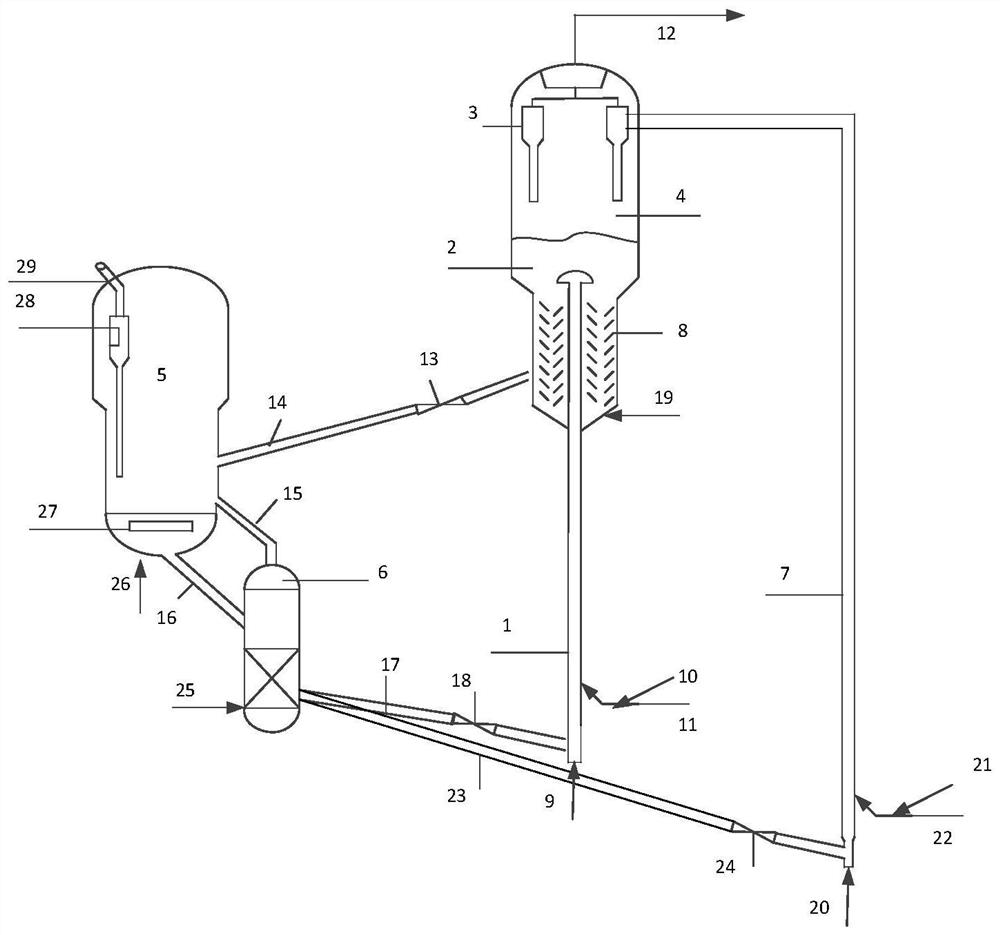

[0070] According to the first embodiment of the present invention, the conditions of the first riser reactor include: the reaction temperature (outlet temperature) is 550-720°C, preferably 580-700°C, and the reaction time is 1-10 seconds, preferably 1.5-6 seconds, the reaction pressure (gauge pressure) is 0.13-1 MPa, preferably 0.25-0.4 MPa, and the agent-oil weight ratio is 1-100, preferably 10-50, more preferably 20-40; The conditions of the fluidized bed reactor may include: the reaction temperature is 530-730°C, preferably 560-680°C, more preferably 610-660°C, and the reaction time is 1-20 seconds, preferably 3-15 seconds, more preferably Preferably 3-10 seconds; the reaction conditions of the second riser reactor can include: the reaction temperature (outlet temperature) is 460-720°C, preferably 500-660°C, more preferably 560-650°C, the reaction time is 1-10 seconds, preferably 1-6 seconds, the reaction pressure (gauge pressure) is 0.1-1 MPa, preferably 0.2-0.4 MPa, and t...

preparation example

[0087] The preparation method of catalytic cracking catalyst A used in the embodiment is as follows:

[0088] 1) Filter the mother liquor from the crystallized β molecular sieve (produced by Changling Catalyst Factory), wash with water, filter and dry; roast the dried molecular sieve in the air for 6 hours at a temperature of 550°C to remove the templating agent Get above-mentioned molecular sieve 100 grams (dry basis) and add in the NaOH solution of 1000 grams 2.4% by weight, be warming up to 65 ℃, after reacting for 30 minutes, after rapidly cooling to room temperature, filter, wash to filtrate neutrality. Then, add 800 grams of water to the filter cake to make a slurry, add 40 grams of NH 4 Cl, heated to 75°C, exchanged for 1 hour, to Na 2 The O content is lower than 0.2% by weight, filtered and washed to obtain a molecular sieve filter cake; take 50 grams (dry basis) of the above-mentioned molecular sieve and add water to prepare a molecular sieve slurry with a solid cont...

Embodiment 1

[0091] This embodiment is used to illustrate the method for producing light olefins described in the present invention.

[0092] according to figure 1 The process shown in the test is carried out on a medium-sized device. The heavy oil raw material is atmospheric residue Z, and its properties are shown in Table 1. The catalyst is catalyst A. The preheated feed oil (350 ° C) enters the first riser reactor. The first catalytic cracking reaction is carried out at the bottom, and the obtained oil agent enters the fluidized bed reactor from the outlet of the first riser reactor to continue the second catalytic cracking reaction. Separation, the reaction product was further separated to obtain products such as ethylene, propylene, and middle distillate AM with a distillation range of 160-220 ° C. The properties of the middle distillate AM are listed in Table 2.

[0093] The middle distillate oil AM is subjected to a hydrotreating reaction with a hydrotreating catalyst, and the cond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com