Preparation method of functional nanoparticle doped polymer antibacterial fiber membrane

A technology of nano-particles and antibacterial fibers, applied in the field of polymer antibacterial fiber membranes and its preparation, can solve problems such as difficult to achieve high-efficiency antibacterial effects, and achieve beneficial sterilization and healing, low cost, and obvious antibacterial activity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) Preparation of up-conversion nanoparticles (UCNPs): 100mgYCl 3 ,20mgYbCl 3 and 1mgTmCl 3 Add deionized water to obtain mixed solution A. Sodium hydroxide (0.5g), water (1mL), ethanol (5mL) and oleic acid (10mL) were stirred evenly to obtain mixed solution B. Add the mixed solution B into the solution A, stir and mix evenly at room temperature, transfer to a polytetrafluoroethylene reactor, react in an oven at 190 degrees Celsius for 24 hours, and cool to room temperature. The final product was obtained by centrifugation.

[0026](2) TiO-coated upconversion nanoparticles (UCNP@TiO 2 ) preparation: add 10 mg of UCNPs into 20 mL of a mixed solution of n-butyl titanate (TBOT) / water / ethanol (v / v=1 / 2 / 100), stir and centrifuge to obtain the obtained product.

[0027] (3) UCNP@TiO 2 Preparation of @GO composite nanoparticles: 0.015g UCNP@TiO 2 Add 1mgGO to 20mL water, stir well, react at 120°C for 12h, and centrifuge to obtain the product.

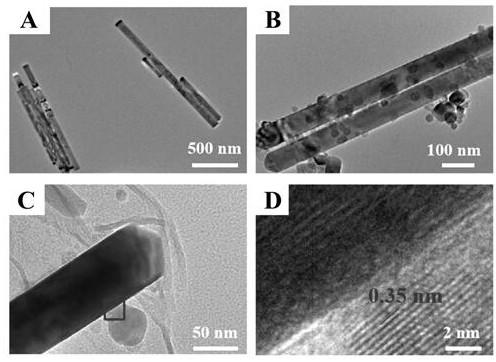

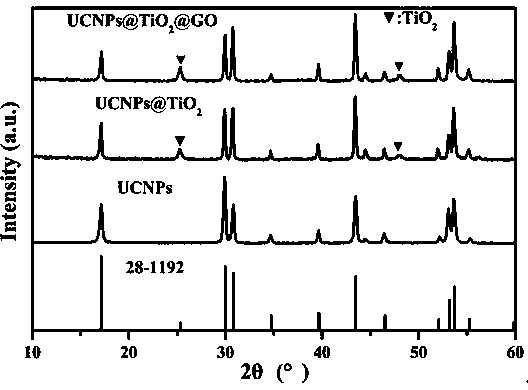

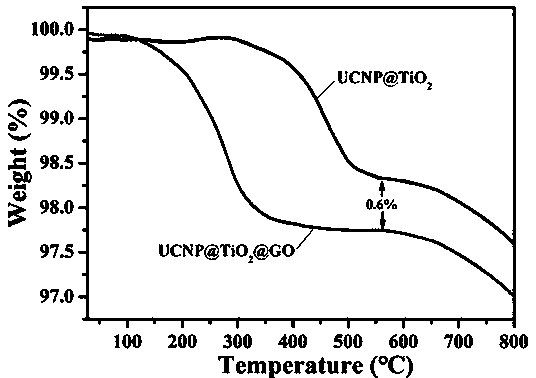

[0028] figure 1 For the...

Embodiment 2

[0043] (1) Preparation of up-conversion nanoparticles (UCNPs): 200mgYCl 3 ,100mgYbCl 3 and 50mgTmCl 3 Add deionized water to obtain mixed solution A. Sodium hydroxide (2g), water (5mL), ethanol (15mL) and oleic acid (50mL) were stirred evenly to obtain mixed solution B. Add the mixed solution B into the solution A, stir and mix evenly at room temperature, transfer to a polytetrafluoroethylene reactor, react in an oven at 200 degrees Celsius for 6 hours, and cool to room temperature. The final product was obtained by centrifugation.

[0044] (2) TiO-coated upconversion nanoparticles (UCNP@TiO 2 ) preparation: add 20 mg of UCNPs into 20 mL of a mixed solution of n-butyl titanate (TBOT) / water / ethanol (v / v=1 / 2 / 200), stir and centrifuge to obtain the product.

[0045] (3) UCNP@TiO 2 Preparation of @GO composite nanoparticles: 0.1g UCNP@TiO 2 Mix with 1mgGO in 20mL water, stir well, react at 120°C for 1h, and centrifuge to obtain the product.

[0046] (4) Polyvinylidene fluo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com