A flexible transparent conductive film based on graphene/silver nanowires/chitosan

A transparent conductive film, silver nanowire technology, applied in graphene, equipment for making conductive/semiconductive layers, nanocarbons, etc. Density, the effect of avoiding the existence of voids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

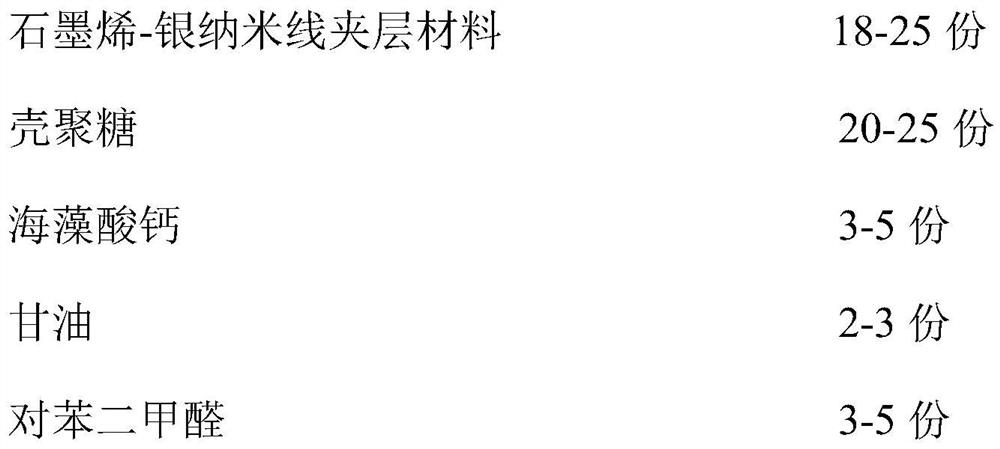

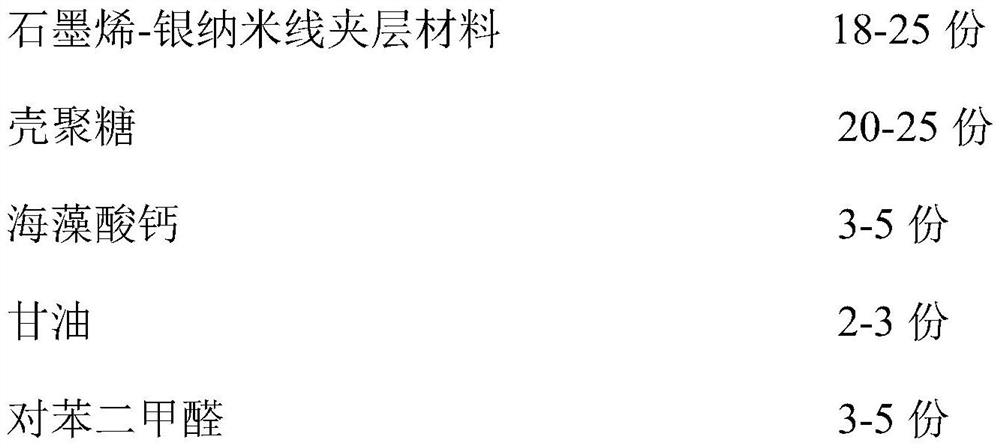

[0022]Next, the technical scheme in the embodiment of the present invention will be described in conjunction with the embodiment of the present invention, which is apparent from the embodiments of the present invention, and not all of the embodiments of the invention, not all of the embodiments of the invention. Based on the embodiments of the present invention, there are all other embodiments obtained without making creative labor without making creative labor premises.

[0023]Layer hydroxyl groups substituted with amino-substituted graphene:

[0024]The dimethylformamide solution of the oxidized graphene and mass fraction of 1 to 5% is 1: 10-1: 20, in the reactor, at a temperature of 75-80 ° C, at a temperature of 75-80 ° C. The stirring speed was 200-600 R / min, and the mixture was heated and stirred for 1-5 hours, filtered, cake, and dried the resulting filter to a temperature of 105-110 ° C to constant weight, pretreatment of oxide oxide After mixing pretreatment of graphene and te...

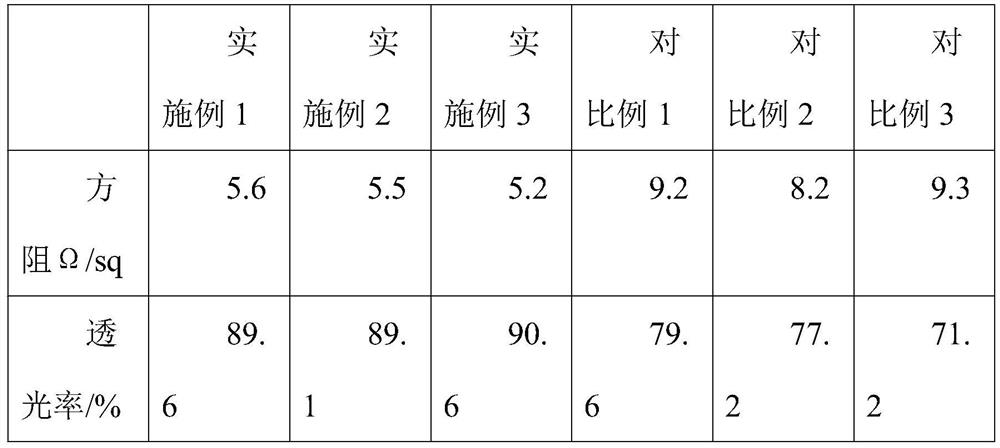

Embodiment 1

[0040]Layer hydroxyl groups substituted with amino-substituted graphene:

[0041]The dimethylformamide solution of the oxide and mass fraction of 1% is 1% by mass is mixed into the reactor in a mass ratio of 1:10, at which the temperature is 75 ° C, the stirring speed is 200R / min. After heating and stirring reaction for 1 h, filtered, cake, and dried the resulting filter to a temperature of 105 ° C to constant weight, pretreatment of oxide oxide; pretreatment of graphene and tetrahydrofuran, according to mass ratio 1 After mixing, after mixing, the ultrasonic frequency is 40 kHz, and the ultrasonic dispersion is 40 min. After the ultrasonic dispersion is completed, the pretreatment of the graphemene mass 1% hydride is added, at a temperature of 55 ° C, stirring the rotation speed of 400R / min. Under the conditions, the reaction was heated and stirred for 1 h, filtered, cake, and dried the resulting filter to the temperature of 105 ° C to a constant weight, and the hydroxyl group was...

Embodiment 2

[0057]Layer hydroxyl groups substituted with amino-substituted graphene:

[0058]The dimethylformamide solution of the oxide oxide and mass fraction of 3% is mixed into the reactor in a mass ratio of 1: 15, at a temperature of 78 ° C, stirring the rotation speed of 400R / min. After heating and stirring, the reaction was stirred, filtered, cake, and dried the resulting filter to a temperature of 108 ° C to constant weight, pretreatment of oxide oxide; pretreatment of graphene and tetrahydrofuran, according to mass ratio 1 After mixing, after the ultrasonic frequency is 60 kHz, the ultrasonic dispersion is 50 min. After the ultrasonic dispersion is completed, the pretreatment of the graphel oxide mass 3% hydrogenated aluminum hydride is added, at a temperature of 60 ° C, stirring the rotation speed of 450 r / min. Under the conditions, the reaction was heated and stirred for 2 h, filtered, cake, and dried the resulting filter to a constant weight at a temperature of 108 ° C, and a hydro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com