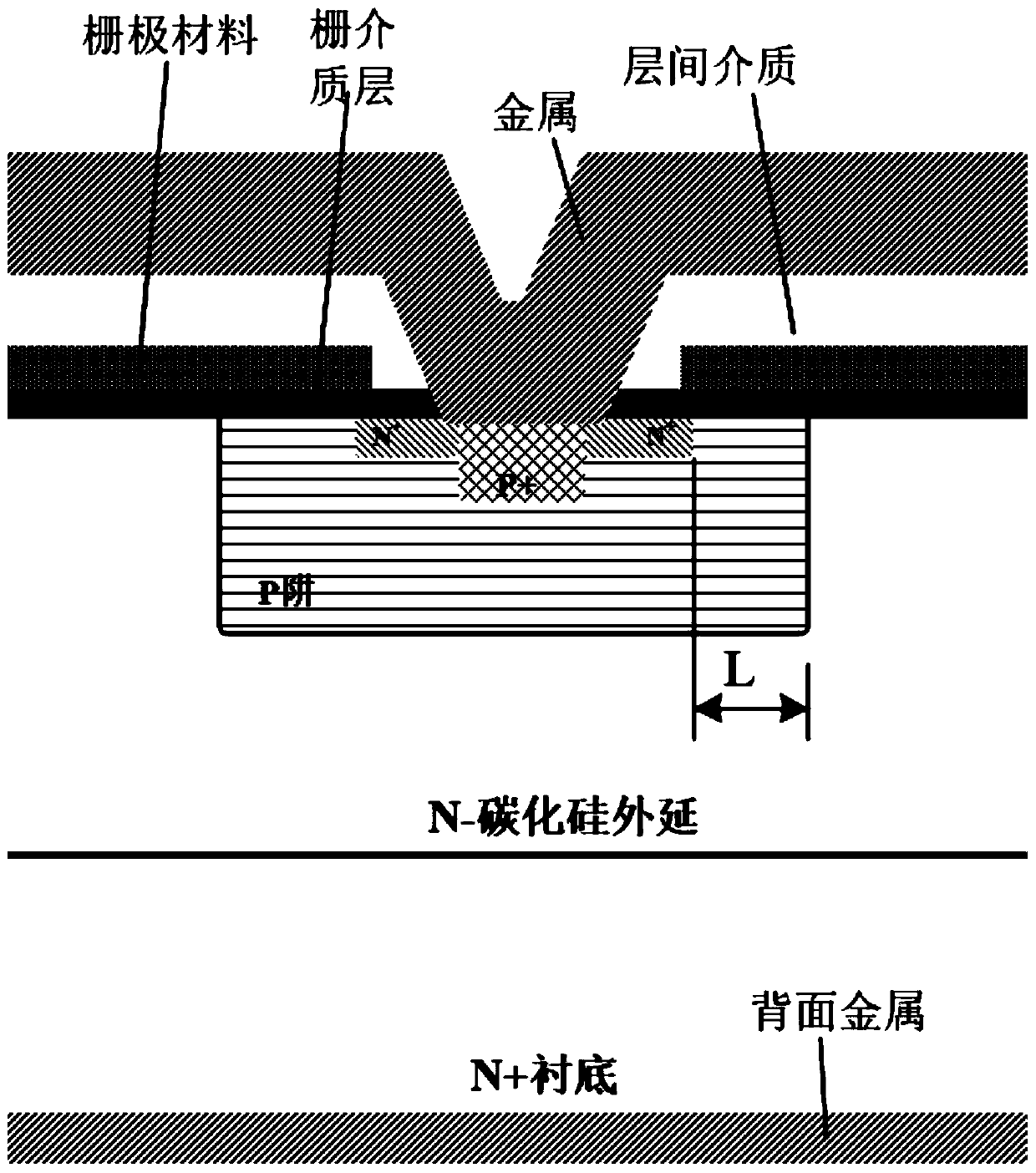

Short-channel silicon carbide MOSFET device integrating Schottky diode and manufacturing method of short-channel silicon carbide MOSFET device

A technology of Schottky diodes and manufacturing methods, which is applied in semiconductor/solid-state device manufacturing, diodes, semiconductor devices, etc., can solve the random discrete distribution of device performance, affect the consistency of device parameters, etc., and reduce the on-resistance Ron , reduce device cost, and improve consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to deepen the understanding and recognition of the present invention, the present invention will be further described and introduced below in conjunction with the accompanying drawings.

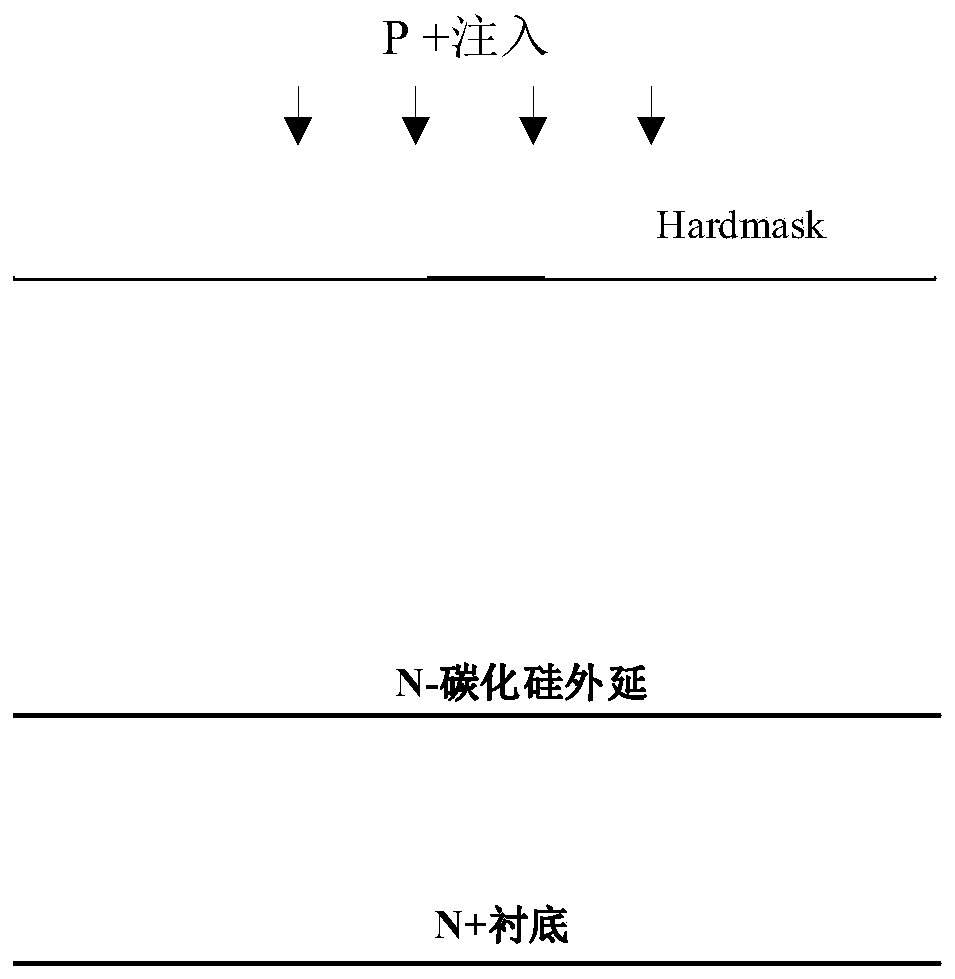

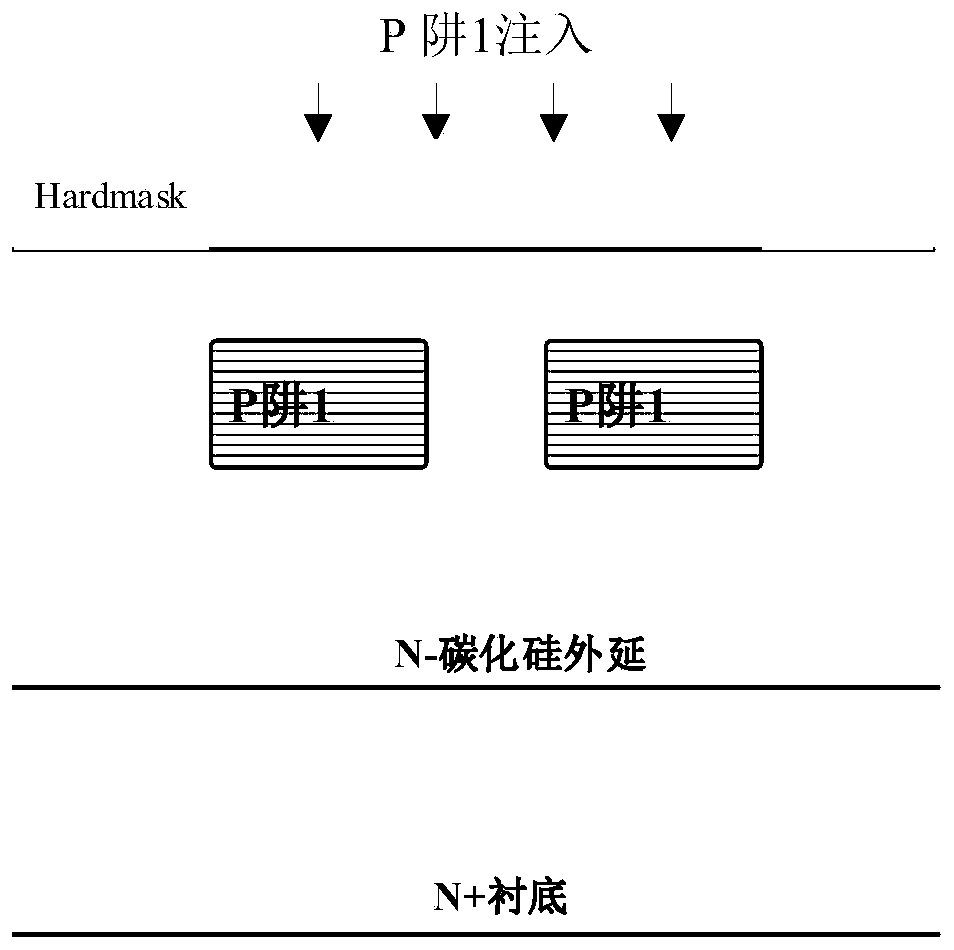

[0028] Such as Figure 2-8 As shown, a method for manufacturing a short-channel silicon carbide MOSFET device integrating a Schottky diode comprises the following steps:

[0029] (1) Deposit an N-silicon carbide epitaxial layer on the upper surface of the N+ silicon carbide substrate. The concentration and thickness of the N-silicon carbide epitaxial layer are determined according to the withstand voltage value of the device. The LPCVD or PECVD process is used on the silicon carbide epitaxial layer Deposit a layer of hardmask, coat photoresist on the hardmask, photolithography and etch the hardmask, and then inject P-type impurities into the silicon carbide epitaxial layer to form a P+ contact, which is used to form the contact of the device well region, using a wet method Or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com