Blue perovskite film and blue perovskite light-emitting diode

A light-emitting diode, perovskite technology, applied in semiconductor devices, electrical components, circuits, etc., to achieve the effects of simple preparation process, narrow half-peak width, and stable light color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] This embodiment provides a blue light perovskite light-emitting diode, and the preparation method thereof includes the following steps:

[0041] Step 1: The ITO transparent conductive glass substrate is cleaned and dried in a standardized manner and then pretreated;

[0042] Step 2: Transfer the ITO to the glove box, spin-coat the PVK organic solution with a concentration of 6 mg / mL and a spin-coating speed of 4000 rpm. After the spin-coating, a hole transport layer is formed on the surface of the ITO transparent conductive glass with a thickness of 40 nm. ;

[0043] Step 3: Press the general formula (PEABr) m (NPABr 2 ) c (CsBr) n PbBr 2 The ratio of PEABr and NPABr is added to the solvent 2 , CsBr and PbBr 2 , configured to obtain a perovskite precursor solution, PbBr in the perovskite precursor solution 2 The molar concentration of is 0.08mM / mL, wherein, m=0.8, c=0.4, n=1, and the solvent is DMSO;

[0044]Step 4: spin coating the precursor solution obtained ...

Embodiment 2

[0048] This embodiment provides a blue light perovskite light-emitting diode, the preparation method of which is the same as that in embodiment 1, the difference is that in step 3, in the perovskite precursor solution, the ratio of each component is adjusted to m= 0.9, c=0.6, n=1.

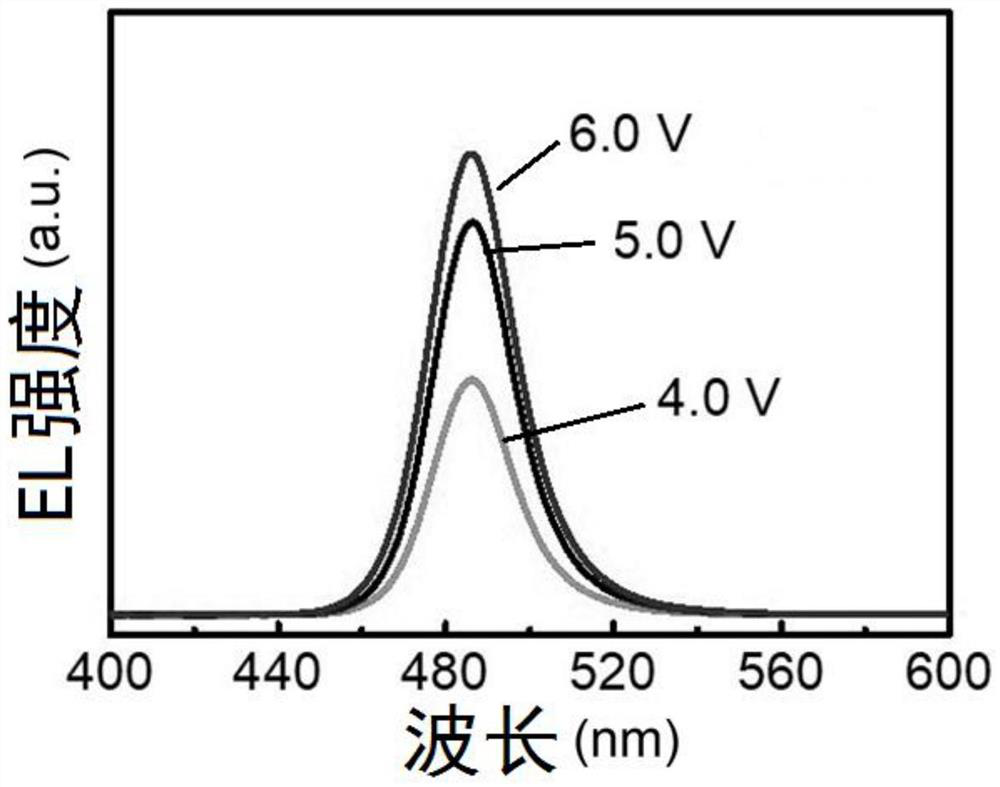

[0049] The electroluminescence spectra of the above prepared perovskite light-emitting diodes are as follows: Figure 4 , the results show that the peak position is 476nm, the half-peak width is 25nm, the spectrum is very stable under different working voltages, and the CIE coordinates are (0.105, 0.153) ( Figure 5 ).

Embodiment 3

[0051] This embodiment provides a perovskite light-emitting diode, the preparation method of which is the same as that in embodiment 1, the difference is that in step 3, in the perovskite precursor solution, the ratio of each component is adjusted to m=0.8 , c=0, n=1.

[0052] The light emitted by the perovskite light-emitting diode prepared above is green light with a peak position of 502 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com