Production method of concentrated green plum juice

A production method and technology for concentrated juice, which are applied in the production field of green plum juice concentrate, can solve the problems of difficulty in extracting juice, high cost, heavy bitterness and astringency, and achieve the effects of shortening drying time, shortening drying time and reducing viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

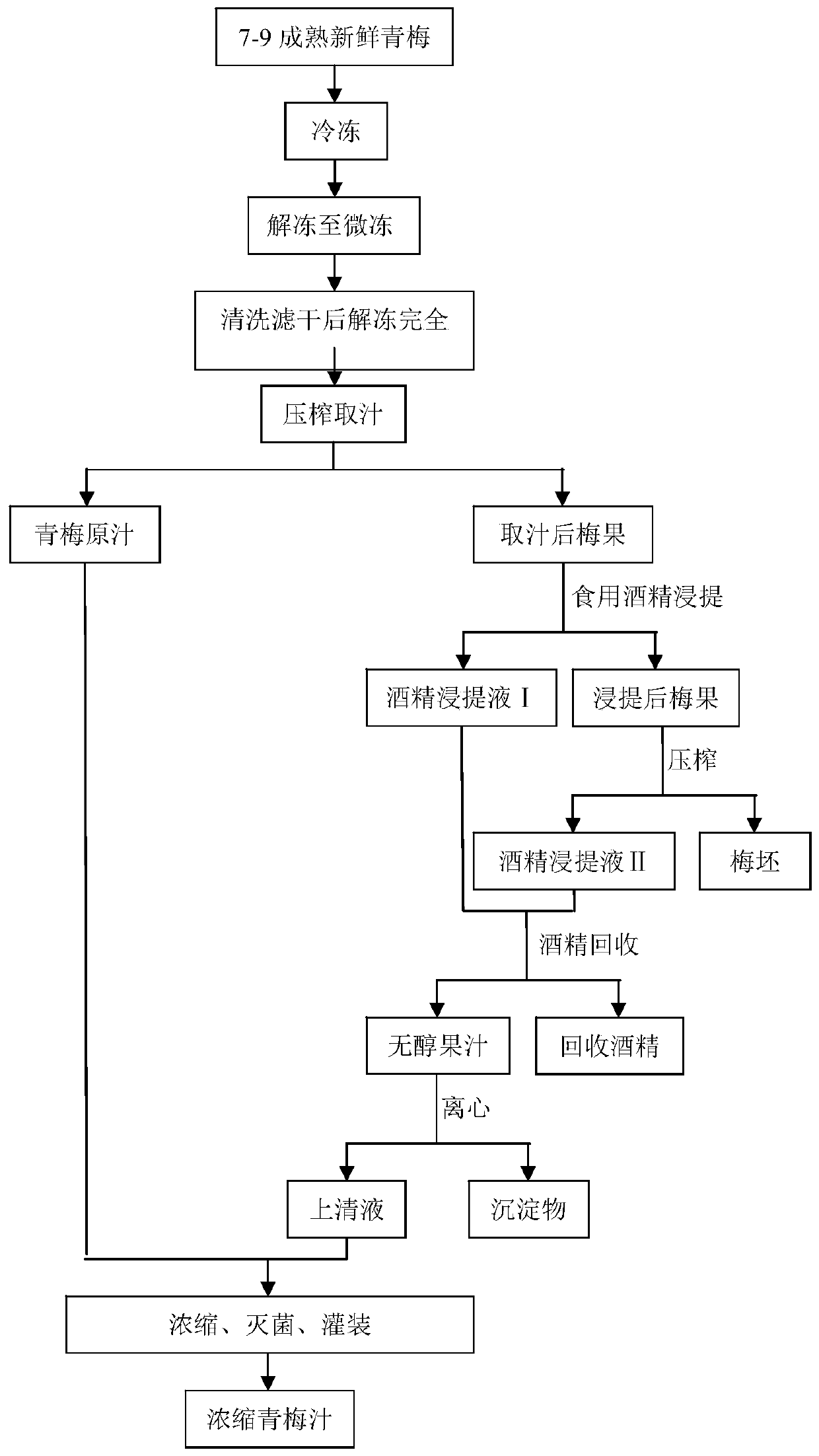

[0039] Such as figure 1 As shown in the example, the method for producing concentrated green plum juice provided in this embodiment includes the following steps:

[0040] (1) Take 1.82 kg of fresh nine-ripe green plums and place them in a -18°C freezer for 48 hours until the green plums are completely frozen.

[0041] (2) Take out the green plum that was completely frozen in step (1), place it in a refrigerator at 4°C for 24 hours, and then place it at room temperature for 4 hours to thaw to a slightly frozen state.

[0042] (3) Wash the green plums in the slightly frozen state with regular tap water, air-dry the surface water, and then thaw completely.

[0043] (4) The thawed green plums are squeezed manually to obtain the juice to obtain 0.56 kg of the green plum juice and 1.26 kg of the plum fruit after the juice is extracted.

[0044] (5) After the juice is taken, the plums are filled in a glass container with a screw cap, and 1000 mL of 95% (v / v) edible alcohol is added, and seale...

Embodiment 2

[0049] Such as figure 1 As shown in the example, the method for producing concentrated green plum juice provided in this embodiment includes the following steps:

[0050] (1) Take 10 kg of fresh nine-ripe green plums and place them in a cold storage at -18°C for 1 week until the green plums are completely frozen.

[0051] (2) Take out the green plum that is completely frozen in step (1), place it in a 4°C freezer for 48 hours, and then place it at room temperature for 4 hours to thaw to a slightly frozen state.

[0052] (3) Wash the green plums in the slightly frozen state with regular tap water, air-dry the surface water, and then thaw completely.

[0053] (4) The thawed green plums were squeezed manually to obtain the juice to obtain 3.45 kg of green plum juice and 6.55 kg of plum fruit after the juice was extracted.

[0054] (5) After the juice is taken, the plums are filled in a glass container with a lid, 30% (v / v) edible alcohol 3.0L is added, and sealed and extracted for 24 hour...

Embodiment 3

[0059] Such as figure 1 As shown in the example, the method for producing concentrated green plum juice provided in this embodiment includes the following steps:

[0060] (1) Take 1,000 kg of fresh nine-ripe green plums and place them in a cold storage at -18°C for 1 week until the green plums are completely frozen.

[0061] (2) Take out the green plum that has been completely frozen in step (1), place it in a 4°C cold storage for 48 hours, and then place it at room temperature for 12 hours to thaw to a slightly frozen state.

[0062] (3) Wash the green plums in the slightly frozen state with regular tap water, air-dry the surface water, and then thaw completely.

[0063] (4) Use a hydraulic juicer to squeeze the thawed green plum to extract the juice, gradually press it until the green plum juice flows out, and stop the pressure when a very small amount of pulp is squeezed out, and hold the pressure for 3 minutes to obtain 350kg of green plum juice. Plum fruit 650kg after juice.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com