Catalyst for preparing iso-octanal through selective hydrogenation of iso-octenal, preparation method and application thereof

A technology for selective hydrogenation and isooctenal, applied in catalytic reactions, organic compound/hydride/coordination complex catalysts, chemical instruments and methods, etc., can solve the problem of reduced palladium dispersion and utilization rate, complicated preparation process and other problems, to achieve the effect of increasing load stability, simple process, and improving dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

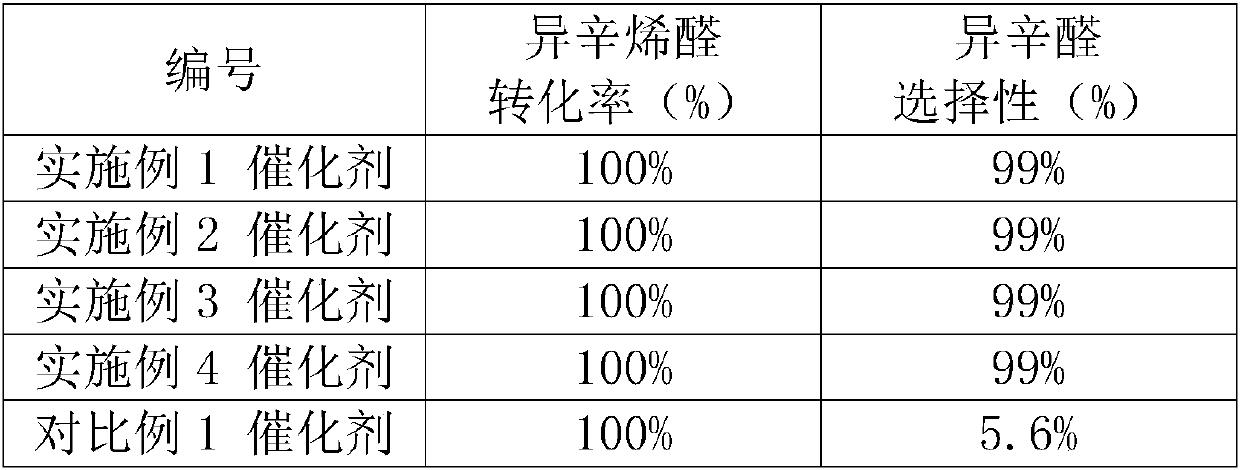

Embodiment 1

[0058] (1) Weigh 20mmol (1.88g) of polyvinylimidazole (PVIM) and dissolve it in 200ml of methanol, and add 50ml of methanol solution with a sulfuric acid concentration of 0.1mmol / ml dropwise under stirring, and a solid substance appears in the solution immediately. After the dropwise addition was completed, keep stirring for 4h. Finally, after vacuum filtration and washing with methanol for 3 times, dry at 80°C for 8h to obtain the sulfuric acid-polyvinylimidazole complex (H 2 SO 4 -PVIM).

[0059] (2) The H obtained above 2 SO 4 - PVIM is dispersed in methanol at a concentration of 0.1 g / ml. Under the condition of stirring, 10 ml of palladium nitrate methanol solution containing palladium with a concentration of 0.05 mmol / ml was added dropwise. After the dropwise addition, keep stirring for 4h. Finally, after vacuum filtration and washing with methanol for 3 times, it was dried at 80°C for 8 hours to obtain a palladium-sulfuric acid-polyvinylimidazole composite catalyst...

Embodiment 2

[0061] (1) Weigh 20mmol (1.88g) of polyvinylimidazole (PVIM) and dissolve it in 200ml of methanol, and add 50ml of methanol solution with a sulfuric acid concentration of 0.1mmol / ml dropwise under stirring, and a solid substance appears in the solution immediately. After the dropwise addition was completed, keep stirring for 4h. Finally, after vacuum filtration and washing with methanol for 3 times, dry at 80°C for 8h to obtain the sulfuric acid-polyvinylimidazole complex (H 2 SO 4 -PVIM).

[0062] (2) The H obtained above 2 SO 4 - PVIM is dispersed in methanol at a concentration of 0.1 g / ml. Take 0.4ml palladium nitrate methanol solution containing palladium concentration of 0.05mmol / ml, dilute it to 20ml with methanol, and add H 2 SO 4 -PVIM in methanol. After the dropwise addition, keep stirring for 4h. Finally, after vacuum filtration and washing with methanol for 3 times, it was dried at 80°C for 8 hours to obtain a palladium-sulfuric acid-polyvinylimidazole compo...

Embodiment 3

[0064] (1) Weigh 20mmol (1.88g) of polyvinylimidazole (PVIM) and dissolve it in 200ml of methanol, and add 10ml of a methanol solution with a sulfuric acid concentration of 0.1mmol / ml dropwise under stirring, and a solid substance appears in the solution immediately. After the dropwise addition was completed, keep stirring for 4h. Finally, after vacuum filtration and washing with methanol for 3 times, dry at 80°C for 8h to obtain the sulfuric acid-polyvinylimidazole complex (H 2 SO 4 -PVIM).

[0065] (2) The H obtained above 2 SO 4 - PVIM is dispersed in methanol at a concentration of 0.1 g / ml. Under the condition of stirring, 60 ml of palladium nitrate methanol solution containing palladium with a concentration of 0.05 mmol / ml was added dropwise. After the dropwise addition, keep stirring for 4h. Finally, after vacuum filtration and washing with methanol for 3 times, it was dried at 80°C for 8 hours to obtain a palladium-sulfuric acid-polyvinylimidazole composite cataly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com