Electrochemical oxygen catalytic reduction cathode material for water treatment and preparation method thereof

A cathode material and oxygen catalysis technology, applied in chemical instruments and methods, water/sewage treatment, oxidized water/sewage treatment, etc., can solve the problem of electrochemical oxygen reduction efficiency, high price, and few wastewater treatment market applications, etc. problem, to achieve the effect of easy electron transfer, convenient operation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

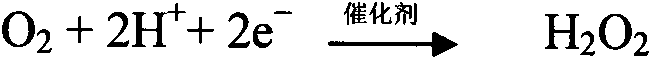

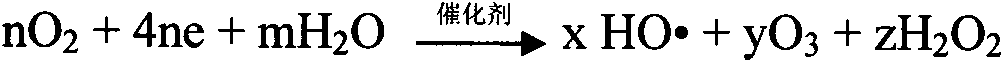

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] An electrochemical oxygen catalytic reduction cathode material for water treatment in this embodiment and its preparation method:

[0041] The metal substrate of the cathode material is a porous Q345 steel material;

[0042] Described preparation method comprises the steps:

[0043] (1) Heat the above-mentioned porous Q345 steel to 150°C in air and keep it for 180min;

[0044] (2) Cool and make a strip electrode. That is, the required cathode material has been prepared.

[0045] The above-mentioned electrode material prepared in this embodiment is applied to the cathode of electrocatalytic degradation of organic wastewater, and the specific application method is as follows:

[0046] (1) design an electrochemical reactor device, be provided with anode and cathode in this device; Anode is an insoluble anode: graphite block, and anode is connected to power supply positive pole by lead; Negative electrode is by the above-mentioned porous Q345 steel that this method is pr...

Embodiment 2

[0049] An electrochemical oxygen catalytic reduction cathode material for water treatment in this embodiment and its preparation method:

[0050] The metal substrate of the cathode material is a foamed nickel alloy material;

[0051] Described preparation method comprises the steps:

[0052] (1) Heat the above-mentioned foamy nickel alloy to 350° C. in sulfur vapor and keep it for 120 minutes without air isolation;

[0053] (2) Cool and make a strip electrode. That is, the required cathode material has been prepared.

[0054] The above-mentioned electrode material prepared in this embodiment is applied to the cathode of electrocatalytic degradation of organic wastewater, and the specific application method is as follows:

[0055] (1) design an electrochemical reactor device, be provided with anode and cathode in this device; Anode is an insoluble anode: graphite block, and anode is connected to power supply positive pole by lead; Negative electrode is by the above-mentioned...

Embodiment 3

[0058] An electrochemical oxygen catalytic reduction cathode material for water treatment in this embodiment and its preparation method:

[0059] The metal substrate of the cathode material is a reticulated 1Cr18Ni9Ti stainless steel material;

[0060] Described preparation method comprises the steps:

[0061] (1) Heat the above mesh 1Cr18Ni9Ti stainless steel to 550°C in a nitrogen atmosphere and keep it for 240min;

[0062] (2) Cool and make a strip electrode. That is, the required cathode material has been prepared.

[0063] The above-mentioned electrode material prepared in this embodiment is applied to the cathode of electrocatalytic degradation of organic wastewater, and the specific application method is as follows:

[0064] (1) design an electrochemical reactor device, be provided with anode and cathode in this device; Anode is an insoluble anode: graphite block, and anode is connected to power supply positive pole by lead; Negative electrode is by above-mentioned r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com