High-transmittance intelligent liquid crystal dimming film and preparation method thereof

A liquid crystal dimming film, high transmittance technology, applied in optics, nonlinear optics, instruments, etc., can solve the problem of high polymer raw material price, high price of intelligent dimming film products, slow development of organic synthesis process, etc. problem, to achieve good photoinitiation efficiency, avoid aggregation and precipitation, and ensure the effect of haze and transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

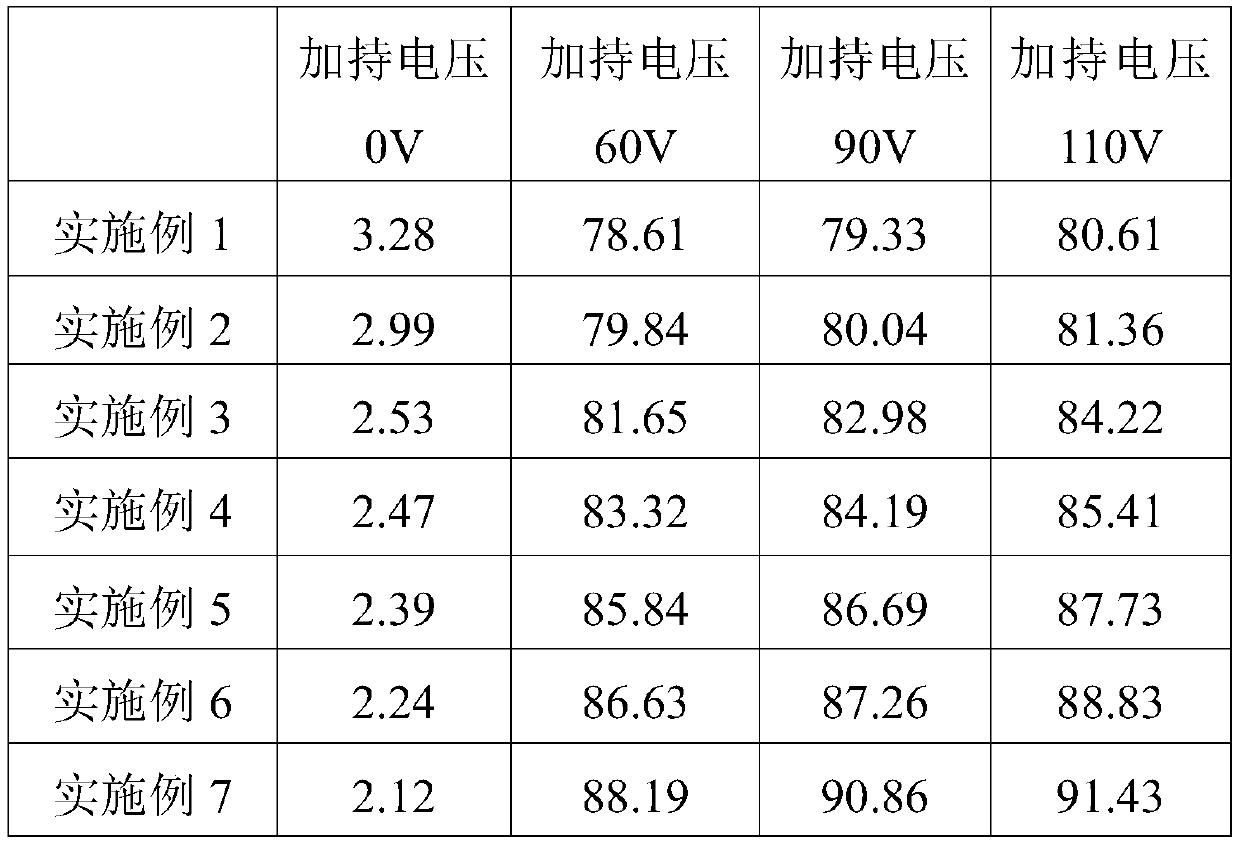

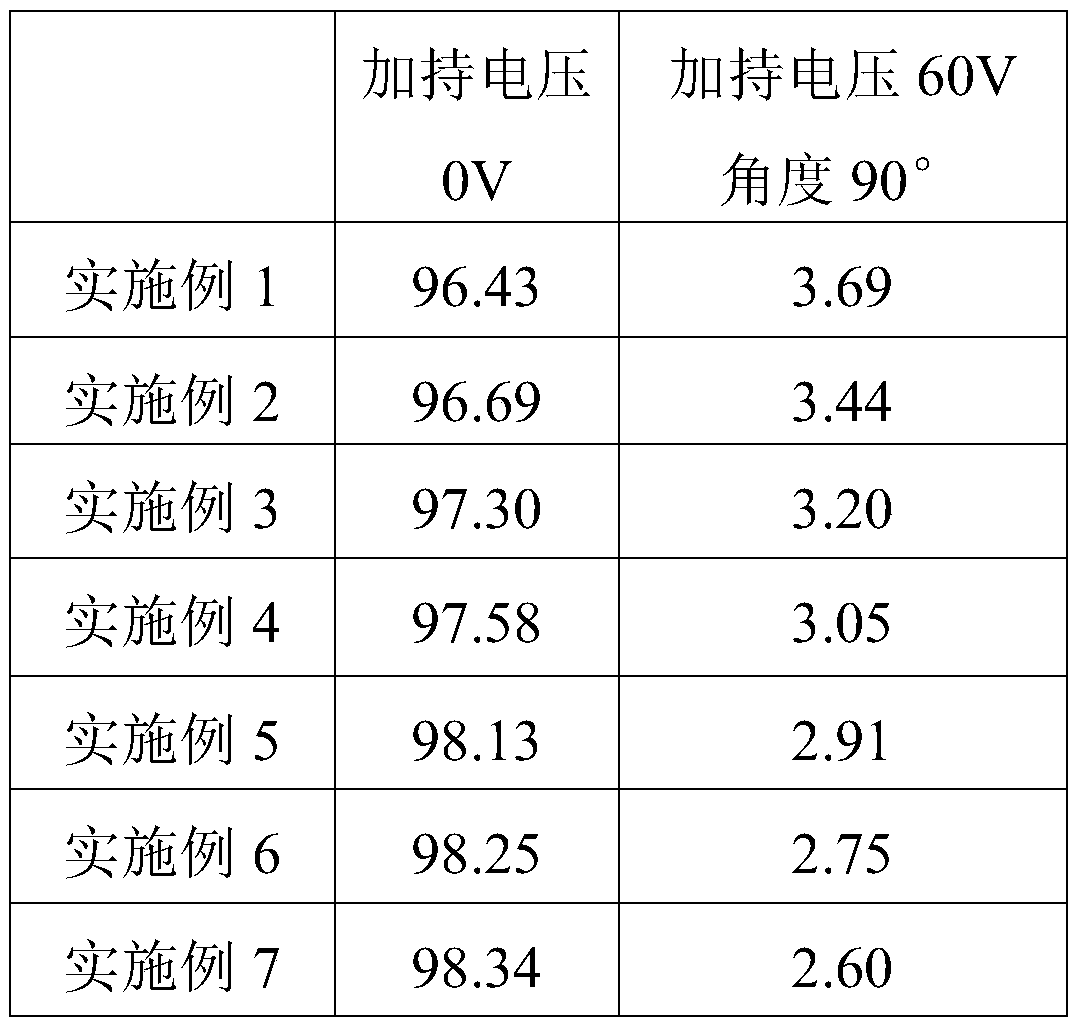

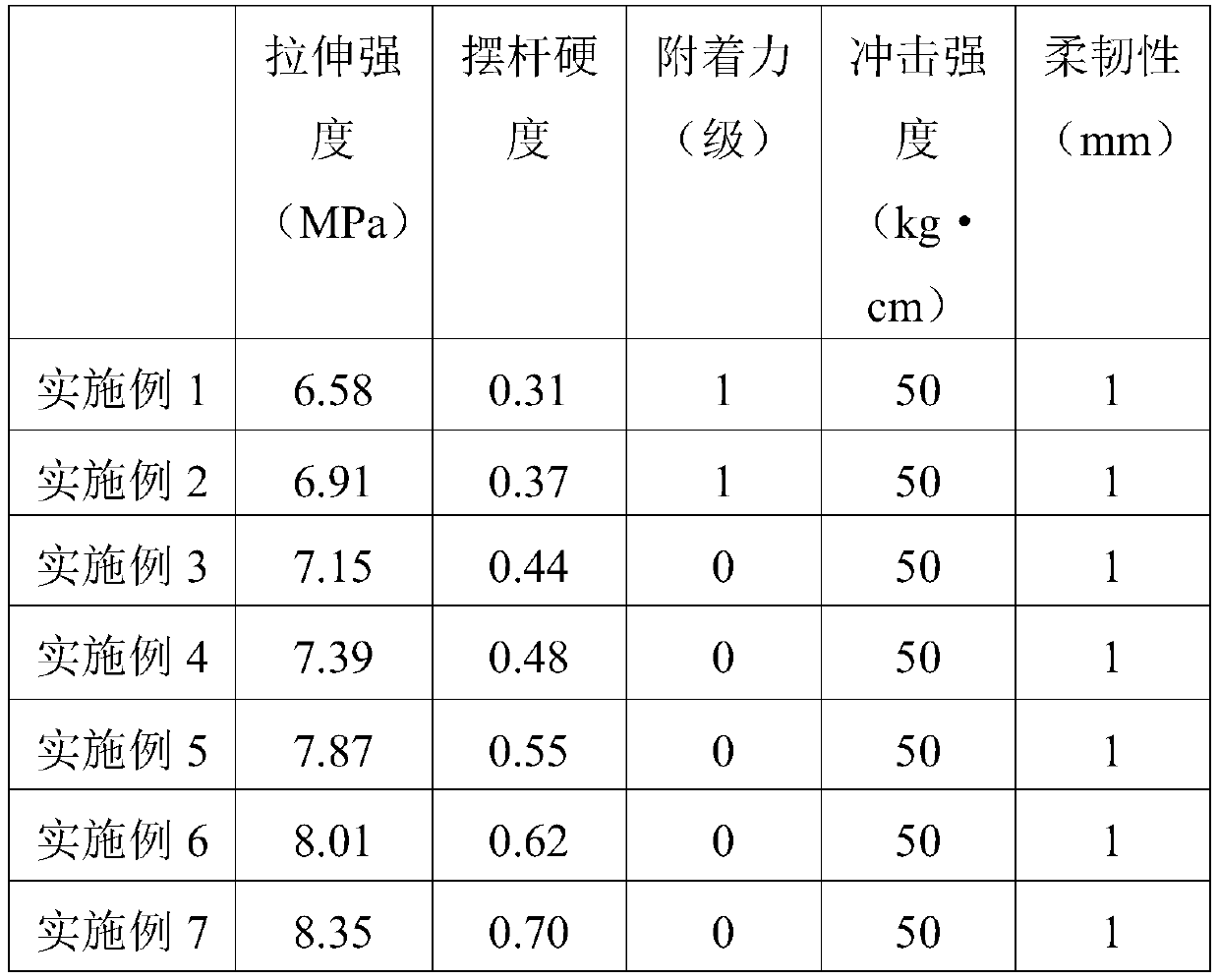

Examples

Embodiment 1

[0059] The preparation method of high transmittance intelligent liquid crystal dimming film comprises the following steps:

[0060] Step S1: Add 30 parts by weight of polyurethane acrylate, biphenyl liquid crystal (for details, use 4'-allyloxy-4-perfluorooctanoyloxy-biphenyl prepared in Example 1 of patent application number 201010165461.6) 50 Parts by weight, hollow glass microspheres (manufacturer Lingshou County Baifeng Mineral Products Processing Plant, particle size 10 μm, wall thickness 1 μm) 1.2 parts by weight, photoinitiator 1173 (chemical name 2-hydroxyl-2-methyl-1-phenyl -1-Acetone, CAS No.: 7473-98-5) 3 parts by weight, polyether modified silicone surfactant (prepared with reference to Example 1 of Patent Application No. 201510054047.0) 1 part by weight, pentaerythritol ester (CAS No. 8050 -10-0) 0.9 parts by weight, fully stirred evenly to obtain a mixed solution;

[0061] Step S2: Place the mixed solution between two conductive films, the conductive layers of th...

Embodiment 2

[0068] The preparation method of high transmittance intelligent liquid crystal dimming film comprises the following steps:

[0069] Step S1: Add 30 parts by weight of polyurethane acrylate, biphenyl liquid crystal (for details, use 4'-allyloxy-4-perfluorooctanoyloxy-biphenyl prepared in Example 1 of patent application number 201010165461.6) 50 Parts by weight, hollow glass microspheres (manufacturer Lingshou County Baifeng Mineral Products Processing Plant, particle size 10 μm, wall thickness 1 μm) 1.2 parts by weight, photoinitiator 1173 (chemical name 2-hydroxyl-2-methyl-1-phenyl -1-Acetone, CAS No.: 7473-98-5) 3 parts by weight, polyether modified silicone surfactant (prepared with reference to Example 1 of Patent Application No. 201510054047.0) 1 part by weight, pentaerythritol ester (CAS No. 8050 -10-0) 0.9 parts by weight, fully stirred evenly to obtain a mixed solution;

[0070] Step S2: Place the mixed solution between two conductive films, the conductive layers of th...

Embodiment 3

[0078] The preparation method of high transmittance intelligent liquid crystal dimming film comprises the following steps:

[0079]Step S1: Add 30 parts by weight of polyurethane acrylate, biphenyl liquid crystal (for details, use 4'-allyloxy-4-perfluorooctanoyloxy-biphenyl prepared in Example 1 of patent application number 201010165461.6) 50 Parts by weight, hollow glass microspheres (manufacturer Lingshou County Baifeng Mineral Products Processing Plant, particle size 10 μm, wall thickness 1 μm) 1.2 parts by weight, photoinitiator 3 parts by weight, polyether modified silicone surfactant (refer to patent application No. 201510054047.0 prepared in Example 1) 1 weight part, pentaerythritol ester (CAS No. 8050-10-0) 0.9 weight part, fully stirred evenly to obtain a mixed solution;

[0080] Step S2: Place the mixed solution between two conductive films, the conductive layers of the conductive films are placed on the inner side and facing each other, and the mixed solution is coa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com